Understanding how to correctly measure the dimensions of a box is essential for anyone working with packaging, traveling, or household storage. Whether you are a business owner choosing custom packaging or a person who need to pack the item for shipping, accurate measurements will help protect your items; save you money and big stess to pack up your stuff.

The significance of accuracy of box measurements goes well beyond logistical convenience. Products may be damaged during shipment if they are too loose, or the package could be unattractive or too heavy if the fit is too tight. This all-in one guide will help to teach you the fundamental skills and information needed to measure a box correctly.

Before reading the article let me ask you if you are interested in custom packaging solutions, check our custom packaging products.

Understanding Box Dimensions: The Foundation of Proper Measurement

The Standard Dimension Format: LxWxH

The packaging industry universally follows a specific order when recording box measurements. The standard format lxwxh represents length, width, and height respectively. This consistent approach ensures clear communication between manufacturers, suppliers, and customers worldwide.

When professionals discuss width x depth x height measurements, they’re referring to the same three-dimensional aspects of a container. Understanding this terminology prevents confusion and ensures accurate specifications for your packaging needs.

The Three Essential Dimensions Explained

Length: The longest horizontal side when viewing the box from above. This dimension runs parallel to the opening edge in most standard rectangular boxes.

Width: The shorter horizontal side when looking at the box from the top view. Sometimes referred to as the depth width height measurement sequence.

Height (or Depth): The vertical dimension extending upward from the base. Industry professionals often use depth by width by height or height depth width interchangeably, depending on the box orientation.

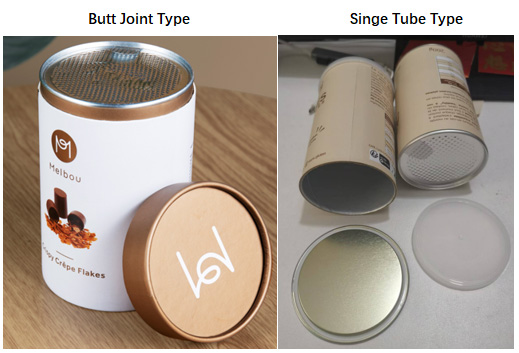

Source: paper tube packaging specifications

How Are Box Dimensions Read: Industry Standards and Best Practices

Standard Reading Order

Understanding how are box dimensions read correctly is crucial for professional packaging operations. The industry standard follows this sequence:

- Length (L) – Always listed first

- Width (W) – Second measurement

- Height/Depth (H/D) – Final measurement

This length width and height format ensures consistency across all packaging communications. Whether you encounter measurements as width height and length in some contexts, the standard remains length x width x height for professional applications.

Reading Dimension Formats

Different notation styles exist for expressing box measurements:

- Height length and width format: Used in some regional contexts

- Width by height by depth notation: Alternative professional format

- Dimension width height depth specification: Technical documentation style

- Height width and depth arrangement: Manufacturing specification format

Source : Packaging industry standards documentation

Step-by-Step Guide: How to Read Size Dimensions Accurately

Step 1: Gather Proper Measuring Tools

Accurate measurement requires appropriate tools:

- Steel tape measure (preferred for rigidity)

- Ruler for smaller boxes

- Digital calipers for precision measurements

- Notepad for recording dimensions

Step 2: Identify Box Orientation

Before measuring, determine the box’s intended orientation:

- Standard shipping position: Base flat on surface

- Display orientation: How the product will be presented

- Storage configuration: Stacking or shelving arrangement

Step 3: Measure Internal Dimensions (Critical!)

Always measure width height and length from the inside of the box. Internal measurements provide the actual usable space and ensure proper fit for contents.

Why Internal Measurements Matter:

- Account for material thickness

- Ensure product fit accuracy

- Prevent measurement errors

- Match industry standards

Step 4: Record Measurements in Standard Order

Document your findings using the height length width depth or standard lxwxh format:

- Length: _____ inches/cm

- Width: _____ inches/cm

- Height: _____ inches/cm

Source: How to Get Right Size on Custom Paper Tube Container for Your Product: A Manufacturer’s Guide

Advanced Measurement Considerations

Understanding Width x Height x Length Variations

Different industries may present dimensions in varying orders. Understanding width length height depth relationships helps interpret specifications correctly regardless of format presentation.

Common Variations:

- Height width depth (manufacturing specs)

- Width height depth (shipping documentation)

- Depth height width (storage planning)

Material Thickness Impact

Box material significantly affects measurement accuracy:

Paper Tube Packaging: Typically 2-4mm wall thickness Corrugated Cardboard: 3-6mm depending on flute size Rigid Boxes: 1-3mm material thickness

Specialized Measurement Scenarios

Cylindrical Containers (like paper tubes):

- Diameter replaces length and width

- Height remains vertical measurement

- Internal diameter critical for content fit

Irregular Shapes:

- Measure maximum dimensions

- Note critical fit points

- Consider product insertion requirements

Common Measurement Mistakes and How to Avoid Them

External vs Internal Dimension Confusion

The most frequent error involves measuring external rather than internal dimensions. This mistake can result in:

- Products that don’t fit properly

- Wasted packaging materials

- Increased shipping costs

- Customer dissatisfaction

Inconsistent Units of Measurement

Always maintain consistent units throughout the measurement process:

- Use inches or centimeters exclusively

- Convert measurements before calculations

- Double-check unit specifications with suppliers

Rounding Errors

Precision matters in packaging:

- Round to appropriate decimal places

- Consider manufacturing tolerances

- Account for material expansion/contraction

Calculating Box Volume and Capacity

Basic Volume Calculation

Once you have accurate height length and width measurements, calculate volume using:

Volume = Length × Width × Height

This calculation helps determine:

- Material requirements

- Shipping costs

- Storage efficiency

- Product capacity

Practical Volume Applications

Understanding box volume supports various business decisions:

Shipping Optimization: Match box sizes to carrier requirements Storage Planning: Maximize warehouse efficiency Material Usage: Minimize waste in custom packaging Cost Analysis: Compare packaging options effectively

Volume Conversion Considerations

Different measurement systems require conversion:

- Cubic inches to cubic feet

- Cubic centimeters to liters

- International shipping standards

Measuring Different Box Types

Standard Rectangular Boxes

The most common packaging format follows traditional width x depth x height measurement principles:

- Place box on flat surface

- Identify longest side (length)

- Measure perpendicular sides (width, height)

- Record in standard format

Square Boxes

When length equals width:

- Measure any horizontal side for length/width

- Maintain standard recording format

- Note square designation in specifications

Tall/Vertical Boxes

For boxes where height width and depth show height as the dominant dimension:

- Height becomes most significant measurement

- Length and width may be similar

- Orientation affects handling requirements

Quality Assurance in Box Measurement

Double-Check Procedures

Implement verification steps:

- Measure twice for accuracy

- Have second person verify critical dimensions

- Compare with product requirements

- Confirm with packaging supplier specifications

Documentation Best Practices

Maintain clear measurement records:

- Date and time of measurements

- Person responsible for measuring

- Tools used for measurement

- Environmental conditions (temperature affects some materials)

Tolerance Considerations

Understanding acceptable measurement variations:

- Manufacturing tolerances (typically ±2-3mm)

- Material expansion factors

- Assembly variations

- Quality control standards

Source: Quality control

Technology and Tools for Enhanced Accuracy

Digital Measurement Solutions

Modern technology offers improved measurement accuracy:

Digital Calipers: Precision measurement to 0.01mm Laser Measuring Tools: Contactless dimension capture 3D Scanning: Complete dimensional analysis Mobile Apps: Augmented reality measurement assistance

Professional Measurement Services

For critical applications, consider professional measurement services:

- Certified dimensional analysis

- CAD drawing creation

- Tolerance verification

- Quality assurance documentation

Integration with Design Software

Connect measurements with design processes:

- CAD software integration

- Automated specification generation

- Design validation tools

- Manufacturing file preparation

Source: Packaging design software recommendations

Industry-Specific Measurement Considerations

E-commerce Packaging

Online retail packaging requires special attention to:

- Shipping carrier restrictions

- Product protection requirements

- Unboxing experience design

- Return packaging considerations

Industrial Packaging

Heavy-duty applications demand:

- Structural load calculations

- Material stress analysis

- Transportation requirement compliance

- Safety standard adherence

Food and Pharmaceutical Packaging

Regulated industries require:

- Precise volume calculations

- Contamination prevention measures

- Regulatory compliance documentation

- Traceability requirements

Measuring for Custom Packaging Orders

Pre-Production Requirements

Custom packaging demands exceptional measurement accuracy:

- Product Analysis: Measure actual products, not prototypes

- Fit Testing: Account for insertion and removal requirements

- Protection Needs: Consider cushioning and void fill requirements

- Handling Requirements: Plan for human and automated handling

Communication with Suppliers

Effective supplier communication requires:

- Clear dimensional specifications

- Tolerance requirements

- Material preferences

- Quantity considerations

Source: Our custom packaging consultation services

Prototype Testing

Validate measurements through:

- Sample box creation

- Fit and function testing

- Shipping simulation

- User experience evaluation

Troubleshooting Common Measurement Challenges

Irregular Product Shapes

When measuring for non-standard products:

- Identify critical dimensions

- Consider orientation options

- Plan for secure positioning

- Account for protection requirements

Multiple Product Packaging

For boxes containing various items:

- Measure largest product dimensions

- Plan efficient arrangement

- Consider separation requirements

- Optimize space utilization

Environmental Factors

Consider conditions affecting measurements:

- Temperature variations

- Humidity effects on materials

- Seasonal dimensional changes

- Storage condition impacts

Cost Implications of Accurate Measurement

Material Optimization

Precise measurements enable:

- Minimum material usage

- Reduced waste generation

- Optimized cutting patterns

- Improved sustainability metrics

Shipping Efficiency

Accurate dimensions support:

- Optimal carrier selection

- Reduced dimensional weight charges

- Improved loading efficiency

- Lower transportation costs

Storage Optimization

Proper measurements facilitate:

- Efficient warehouse utilization

- Improved inventory management

- Reduced storage costs

- Better organization systems

Add Your Heading Text Here

Future Trends in Box Measurement

Automation and AI

Emerging technologies include:

- Automated measurement systems

- AI-powered dimension optimization

- Predictive sizing algorithms

- Smart packaging solutions

Sustainability Integration

Environmental considerations drive:

- Material reduction strategies

- Recyclability optimization

- Carbon footprint calculation

- Sustainable design principles

Industry 4.0 Integration

Connected manufacturing enables:

- Real-time measurement data

- Quality control automation

- Predictive maintenance

- Integrated supply chain optimization

Conclusion

Mastering how to correctly measure the dimensions of a box is essential for successful packaging operations. Understanding the standard lxwxh format, measuring internal dimensions accurately, and following industry best practices ensures optimal results for any packaging project.

Just keep in mind that accurate measurement is the key to successful packaging. No matter whether you are using paper tubes, corrugated boxes, or tailored boxes, the methodology of this guide will get your professional results.

The commitment to effective measuring solutions has a payoff, with savings in expenses, product preservation, and customer satisfaction. With packaging becoming more and more sustainable and effective, precise dimensional requirements are important.

For specialized packaging needs or custom solutions, consult with packaging experts who can offer expert guidance that caters to your special packing needs.