Printed paper tubes are cylindrical packaging solutions made from eco-friendly materials like kraft paper and cardboard. They are customizable with various printing techniques to showcase vibrant designs, branding, and product information.

Printed paper tubes are versatile and can be used in various applications across different industries:

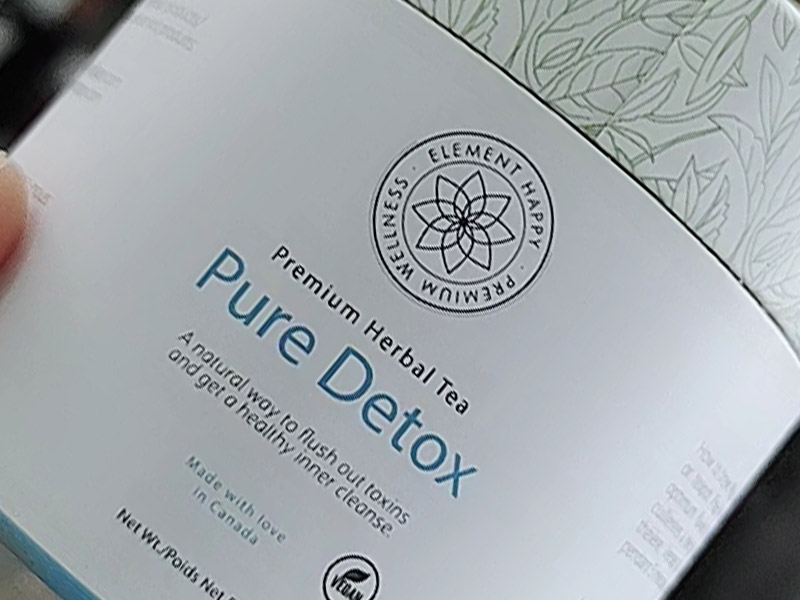

For items like tea, coffee, spices, and snacks, providing an eco-friendly and attractive packaging option.

For lip balms, lotions, and perfumes, offering a sustainable alternative to traditional packaging.

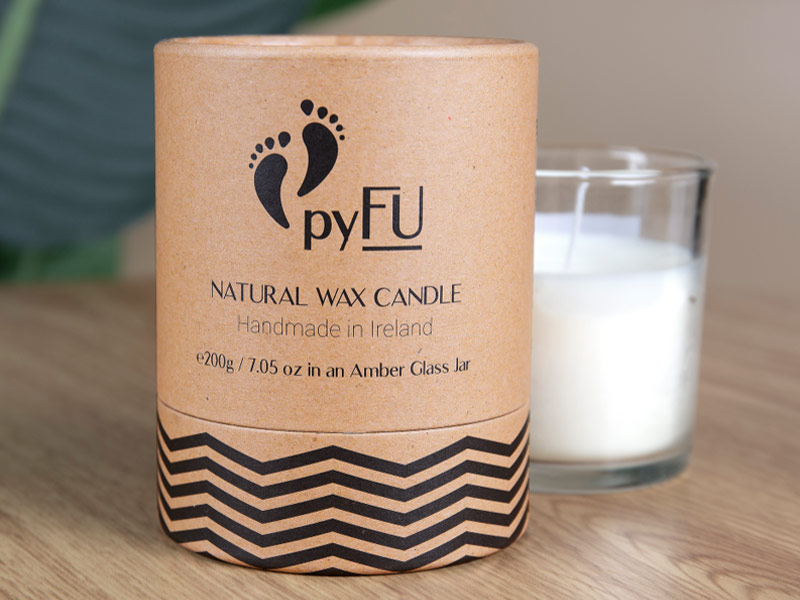

Used for candles, apparel, luxury goods, enhancing the unboxing experience and brand presentation.

Great for wine & spirits, drinks,and bottle packaging, making a memorable impression.

Great for promotional kits, giveaways, and special event packaging, making a memorable impression.

Aligning with brands that prioritize sustainability and eco-friendly practices, supporting green initiatives.

We provide diverse custom services with options for various sizes, materials like kraft and coated papers, and printing techniques such as offset, spot UV, foil stamping, and embossing.

We utilize multiple 360° edge rolling machines and labeling machines, ensuring high-quality, efficient output for all packaging needs.

We operate multiple production lines with a daily capacity of over 10,000 paper tubes and up to 20,000 composite cans, ensuring high efficiency and large-scale output.

A 1-piece paper tube, also known as a single paper tube, is a cylindrical packaging structure made from a single piece of paper or cardboard material.

Unlike multi-piece tubes, which may have separate lids or bases, a 1-piece paper tube is typically a continuous, seamless structure. It can have one end open and the other closed, or it may come with a built-in cap or closure mechanism. The bottom closed end can be iether paper disc closed or metal plug lid sealed.

These printed tubes are often used for packaging products like posters, documents, small gifts, wine, drinks, apparel, and other items that benefit from a simple, protective, and eco-friendly packaging solution.

A 2-piece paper tube, also called a telescopic paper tube. It consists of two separate parts: the main body and a separate cap or lid over the body.

The main body holds the product, while the cap fits snugly over one end of the tube, creating a secure closure. This type of tube offers added convenience and protection, as the cap can be removed and replaced, allowing easy access to the contents.

3-piece printed paper tubes consist of three distinct components: the main body, an inner base, and a separate lid or cap. This design provides additional structure and protection for the contents, as well as more versatility in terms of presentation and functionality. Here’s a breakdown of the components:

Coated paper is a type of paper that has been treated with a coating of materials such as clay or calcium carbonate to create a smoother surface. This coating enhances the paper’s brightness and opacity, making it ideal for high-quality printing.

Printed paper tubes with printing on coated paper produces vibrant, sharp images with enhanced color and detail. Glossy finishes give a bright, reflective look, matte finishes offer a soft, non-glare appearance, and satin finishes provide a balanced sheen.

Kraft paper is a strong, durable paper made from wood pulp using the kraft process. It’s typically brown, though it can be bleached white and black. Known for its toughness, kraft paper is eco-friendly and commonly used in packaging, crafting, and wrapping.

Printing on kraft paper has a rustic and natural look. The paper’s brown color gives printed designs a warm, earthy tone. Darker inks, especially black, stand out well, while lighter colors may appear more muted. The textured surface of kraft paper can add a unique, organic feel to printed materials, making it ideal for eco-friendly and artisanal products.

Specialty paper is a type of paper designed for specific applications or to achieve unique effects. It often has unique textures, colors, finishes, or coatings that set it apart from standard paper types.

Printing on specialty paper can result in unique and visually striking effects, depending on the paper’s texture, color, and finish. Specialty papers can enhance the printed design, adding depth and character, such as metallic sheen, textured surfaces, or vibrant color contrast. The specific look will vary based on the paper’s properties, but it generally creates a premium, distinctive appearance.

Matte lamination is a finishing process that applies a thin, non-glossy film to paper or cardstock. It provides a smooth, soft touch and reduces glare while enhancing durability and resistance to fingerprints and smudges. This finish used on printed paper tubes, gives them an elegant, understated appearance.

Glossy lamination is a finishing process that applies a shiny, reflective film to paper or cardstock. It enhances color vibrancy and sharpness, provides paper tubes a smooth, glossy finish, and increases durability and resistance to moisture and wear.

UV spot coating is a finishing technique where a glossy, UV-cured coating is applied selectively to specific areas of a printed piece. This coating highlights particular elements, such as text or logos, creating a contrasting shine against a matte or non-coated background. It enhance our printed paper tubes’ visual appeal and adds a tactile element to the design.

Hot foil stamping is a printing technique that applies metallic or pigmented foil to paper or other surfaces using heat and pressure. The foil adheres only to the stamped areas, creating a shiny, reflective finish that enhances the design with a luxurious look. It’s often used for special effects on printed paper tubes with high-end printed materials.

Embossing is a technique that creates raised, three-dimensional designs on paper or cardstock. It involves pressing a design into the paper using heat and pressure, producing a tactile effect. Embossing adds texture and a premium look on printed paper tubes.

Debossing is a printing technique that creates a recessed, or indented, design on paper or cardstock. Unlike embossing, which raises the design, debossing presses the design into the paper, giving it a sunken appearance. This technique adds a subtle, elegant texture to printed paper tubes.

Varnish is a clear, protective coating applied to printed materials to enhance their appearance and durability. It can be applied in various finishes—glossy, matte, or satin. It is often used on printed kraft paper tubes.

A bottom push-up paper tube is a type of paper tube with a mechanism that allows the contents to be pushed up from the bottom. It typically features a bottom end that can be manually or mechanically pushed upwards, making it easy to access the product inside as it rises to the top. This design is often used for products like lip balms, salves, or small cosmetics, where convenience and ease of use are important.

A window cutout paper tube has a transparent or semi-transparent window integrated into its design, it can be cut on top cap or body tube. This allows consumers to see part of the product inside without opening the tube. It’s commonly used for showcasing items like cosmetics, candies, or gifts while maintaining the tube’s protective and branding functions..

A ribbon-added paper tube features a decorative ribbon attached to its design. The ribbon can be used for securing the tube, enhancing its visual appeal, or adding a touch of elegance, making it ideal for gifts, special events, and premium packaging.

A neck-exposed paper tube features an exposed or partially exposed neck area of the tube, where the inner content is visible or accessible without a full closure. This design often features a protruding or exposed lip that can be used for easy opening or as a decorative element.

A child lock is a safety feature designed to prevent children from easily opening or accessing the contents of a container or packaging. For paper tubes, it typically involves a secure, often complex, closure mechanism that requires specific actions or strength to open, ensuring that the packaging is child-resistant and helps prevent accidental ingestion or misuse of the product inside.

A holder insert paper tube includes a custom-shaped insert inside the tube to secure and protect the product. This insert is often made of materials like foam or cardboard and is designed to keep items in place, prevent damage, and enhance presentation. It is commonly used for packaging delicate or valuable items.

Printed paper tubes offer a stylish and eco-friendly packaging solution. They enhance brand visibility with custom designs, attract attention with their visual appeal, and provide durable protection for a variety of products. Made from recyclable materials, they are versatile and suitable for numerous applications, making them an excellent choice for both functionality and sustainability.

Eco-Friendly: Made from recyclable materials, contributing to sustainable packaging practices.

Enhanced Product Packaging Experience: Improves customer satisfaction and loyalty with attractive, functional designs.

Brand Value Promotion: Allows storytelling through design, reinforcing brand identity and values.

Visual Appeal: Eye-catching designs attract consumer attention and make products stand out on shelves.

Durability: Provides robust protection for contents while maintaining a high-quality appearance.

Custom size: D108 x H108mm

Material applied: greaseproof paper liner + black kraft paper

Printing applied: CMYK+ PMS 2347C +matt lamination

Shipment: split shipments to meet timeline and save cost.

Expertise

We offer tailor-made packaging solutions based on industry best practices and the latest technology, ensuring your packaging needs are precisely met. Our professional team provides expert advice and solutions for design, material selection, and production processes.

12 Hours Quick Response

We are committed to efficient communication and fast responses to your needs. Whether it’s project inquiries or urgent orders, we handle them swiftly to ensure your packaging projects are completed on time.

Lowest Price Guarantee

We’ll meet or beat any total order price for an identical product and quantity. Our pricing strategy is designed to help you optimize your budget and improve cost efficiency.

Small Quantity Support

We offer flexible options for small batch orders, making it easy for startups or clients needing smaller quantities to achieve their packaging requirements without the pressure of large volume purchases.

High Capacity

We have strong production capabilities to meet large-scale order demands. No matter how substantial your production needs, we deliver stable and efficient services, ensuring timely delivery.

We deliver consistent, high-quality packaging solutions that elevate your product and brand.

Get a fast start with our specialist., to create and customzie your pacakging in a visually appealing way.

All Paper Tube Co. provides intelligent and innovative cardboard paper tube packaging solutions, from design, research, development, and production.

We hope to build a sustainable and greener future for our planet, together with you.

Copyright © 2022 Orr Industrial (Shenzhen) Co. | Sustainable Packaging Solution Provider

It is an easy step, fill out the form and we will be in touch shortly.