Made from recyclable and biodegradable materials, single paper tubes are an environmentally friendly packaging option.

Can be easily customized with various printing options, finishes, and closures to meet branding and product requirements.

Less expensive than other packaging materials like metal or plastic, especially in bulk quantities.

Bottom push-up paper tubes are crafted from biodegradable and recyclable materials, featuring a movable bottom disk, which allows users to easily push the disk upwards, dispensing the product smoothly and efficiently.

The bottom push-up paper tube is a type of packaging primarily used for products like lip balms, solid lotions, deodorants, and other solid or semi-solid products.These innovative tubes provide an eco-conscious alternative to traditional plastic packaging. Try our push-up paper tube packaging today!

The bottom push-up mechanism closely resembles the conventional twist-up design of traditional lip balm packaging. This similarity ensures that the product is dispensed efficiently and smoothly, with no compromise in functionality. The user can easily push the base upwards to release the lip balm, providing a seamless and familiar experience.

The inner lining of the bottom push-up paper tubes is made from food-grade materials, ensuring that it is safe for direct contact with the product. This is particularly important for lip balms, as they are applied to the lips and can be ingested in small amounts. The food-grade lining guarantees that the product remains free from harmful contaminants and safe for everyday use.

Bottom push-up paper tubes are made from recyclable, biodegradable, and compostable materials. This eco-friendly approach significantly reduces the environmental impact compared to traditional plastic packaging. By opting for these sustainable materials, brands can contribute to reducing plastic waste and promoting a more sustainable future.

The height of the top cap and base can be adjusted according to your requirements for bottom push-up paper tubes, with options for either a short or long cap.

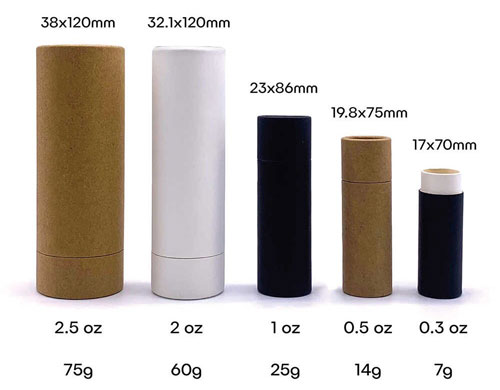

We can customize bottom push-up paper tubes in a range of sizes beyond the regular ones listed above. There are many additional sizes we can create to meet your needs.

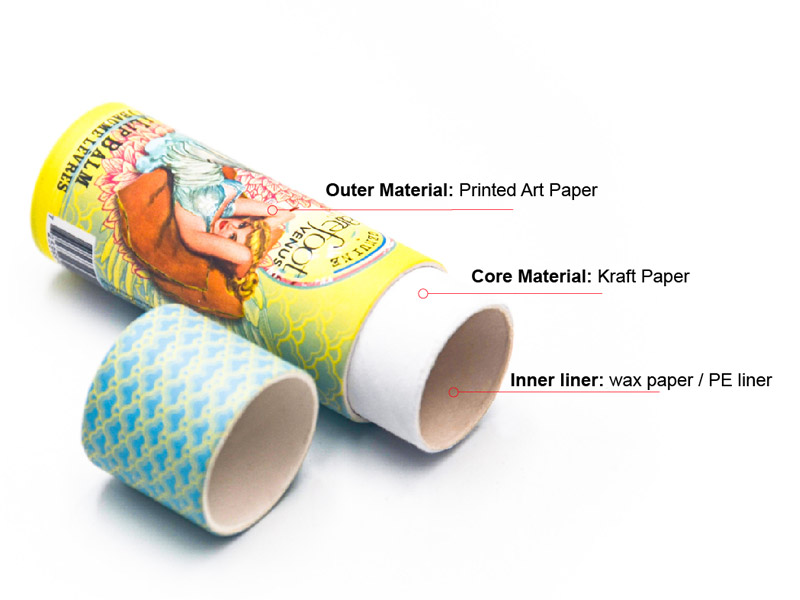

Primary materials:

black / white / brown kraft paper

Inner liner:

waxed paper / greasproof paper / PE liner

Printed materials:

kraft paper / coated artpaper / specialty paper

We provide diverse custom services with options for various sizes, materials like kraft and coated papers, and printing techniques such as offset, spot UV, foil stamping, and embossing.

We utilize multiple 360° edge rolling machines and labeling machines, ensuring high-quality, efficient output for all packaging needs.

We operate multiple production lines with a daily capacity of over 10,000 paper tubes and up to 20,000 composite cans, ensuring high efficiency and large-scale output.

Expertise

We offer tailor-made packaging solutions based on industry best practices and the latest technology, ensuring your packaging needs are precisely met. Our professional team provides expert advice and solutions for design, material selection, and production processes.

12 Hours Quick Response

We are committed to efficient communication and fast responses to your needs. Whether it’s project inquiries or urgent orders, we handle them swiftly to ensure your packaging projects are completed on time.

Lowest Price Guarantee

We’ll meet or beat any total order price for an identical product and quantity. Our pricing strategy is designed to help you optimize your budget and improve cost efficiency.

Small Quantity Support

We offer flexible options for small batch orders, making it easy for startups or clients needing smaller quantities to achieve their packaging requirements without the pressure of large volume purchases.

High Capacity

We have strong production capabilities to meet large-scale order demands. No matter how substantial your production needs, we deliver stable and efficient services, ensuring timely delivery.

Questions you may be concerned about on bottom push-up paper tubes custom.

we can custom any size as per your requirements, any size with your logo.

Following are some regulard sizes we make a lot to other customers asked:

0.14oz (4-5g): D21xH50mm

0.3oz (7-8g): D21xH70mm

0.5oz (14g): D24xH75mm

1.0oz (25g): D26xH86mm

2.0oz (60g): D36xH120mm

Yes, certainly yes!

Our bottom push-up paper tubes, used for lip balm and deodorant, are assuredly food grade and food safe.

The lining used in our lip balm push-up tubes is either waxed paper or greaseproof paper. Both options are food grade and compostable, ensuring safety and sustainability.

Yes, you can surely get sample to check.

And we normally offer samples in 3 different ways:

1. Blank sample: without printing, which allows you to check whether dimensions are correct or not.

2. Digital sample: a sample with correct dimension & structure and printing to check, but printing will be slightly different from bulk production.

3. Physical sample: which cost a bit higher, while it’s totally same as bulk production on dimesion, structure& printing.

If you need ready-stock sample, we will send it randomly, size & printing are not allowed to custom.

We offer two different printing methods:

1. Digital Printing

Digital printing is primarily used for sample production. It is fast and cost-effective. If you prefer offset printing for samples, we can accommodate that as well, though it may be slightly more expensive.

2. CMYK Printing (Offset Printing)

For bulk orders, we use CMYK printing. This method ensures high-quality printing and accurate results as required by our clients.

If your artwork is designed with Pantone colors, we will print it using the specified Pantone color numbers. Please note that the outcome between CMYK printing and Pantone color printing will differ, so it is important to specify any Pantone colors in your artwork.

To learn more about the differences between these printing methods, please click below:

It’ll depend to quantity.

Quantity <5000pcs: about 15-18 days

Quantity 10K-50K pcs: 22-25days

We can make 3-5days shorter for urgent case, which need to communicate with our pacakging specialist.

We can ship orders in different ways by air express, by vessel, by truck and rail. Our pacakging specialist can check cost FYI.

We accpet payment by Paypal, TT bank transfer, West Union, and other ways which work for both us if possible.

Get a fast start with our specialist here.

All Paper Tube Co. provides intelligent and innovative cardboard paper tube packaging solutions, from design, research, development, and production.

We hope to build a sustainable and greener future for our planet, together with you.

Copyright © 2022 Orr Industrial (Shenzhen) Co. | Sustainable Packaging Solution Provider

It is an easy step, fill out the form and we will be in touch shortly.