When it comes to custom paper tube container, getting the right size for your product is critical to ensure that it not only fits snugly but also offers optimal protection and an excellent presentation. As a manufacturer, we understand that choosing the right size can be a complex task, but with the right measurements and considerations, you can achieve a perfect fit that boosts your brand’s image and protects your product during shipping and storage.

1. Introduction to Custom Paper Tube Sizing

In the world of packaging, custom paper tubes are a preferred solution for products that require secure, attractive, and eco-friendly packaging. However, choosing the right size for your custom paper tube is essential to ensure the safety, appeal, and functionality of the packaging. Too tight and your product could be damaged, too loose and it could shift, leading to poor customer experiences. Let’s dive into how you can get the perfect size for your custom paper tube.

2. Understanding the Importance of Proper Sizing

Proper sizing is vital for both the protection and presentation of your product. If your tube is too small, it might crush or damage your product during shipping. If it’s too large, the product could move inside, increasing the chances of breakage. The right size ensures that your product fits securely, stays in place, and is easy for customers to open without any hassle.

3. Key Measurements for Custom Paper Tube Container

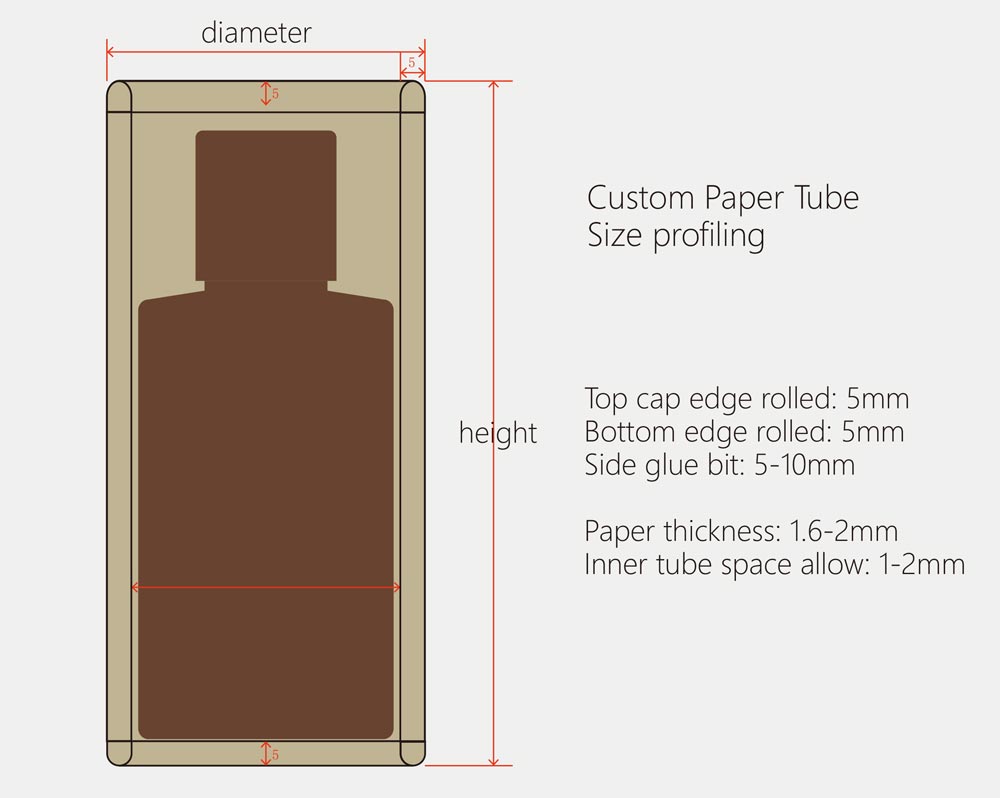

When it comes to sizing, there are a few key dimensions to consider:

Inner Diameter: This should be slightly larger than the product’s outer diameter (about 1 mm larger). This ensures your product fits comfortably inside the tube without being too tight.

Height: The height of the tube should be at least 12 mm greater than the height of the product to allow some buffer space and ensure a secure fit. This extra space will also accommodate the closure mechanism (if any) and prevent crushing.

- Extra Space for Inserts or Padding: If you plan to include inserts (like foam, fabric, or tissue paper) or padding to secure your product, account for the additional space needed. Measure the thickness of the padding and add it to the internal measurements of the tube.

- Consider the Closure Mechanism: If your paper tube has a cap or lid, ensure that the diameter and length are adequate to fit both the product and the closure. You may need to adjust the tube dimensions slightly to accommodate the closure mechanism.

- Test with a Prototype: Once you have the ideal measurements, it’s always a good idea to test your design with a prototype. This helps you confirm that the product fits snugly, is easy to insert and remove, and that the tube will protect the product during storage and transit.

4. Step-by-Step Guide to Measuring Your Product

Measuring your product correctly is crucial for getting the right fit. Here’s a simple, step-by-step guide:

Measure the Diameter: Use a caliper or ruler to measure the widest part of your product. This measurement will determine the diameter of your tube.

Measure the Height: Measure from the base to the top of the product to get the correct height for the tube.

Add Buffer Space: For optimal fit, add 1-2 mm to the diameter and 15-18 mm to the height to ensure that your product fits comfortably without being too tight or too loose.

5. Factors to Consider When Choosing Tube Size

While measuring is important, several other factors should influence your tube sizing decisions:

Product Shape: If your product has an irregular shape, it may require a custom-shaped tube (e.g., oval or square).

Material Thickness: Thicker materials like thick cards or inserts will need more space inside the tube.

Intended Use: Whether the paper tube container is for shipping, display, or retail affects the sizing decision. For example, tubes for retail display may need to be slightly taller or more decorative.

6. Common Mistakes to Avoid in Sizing

Avoiding sizing mistakes can save you from costly errors:

Not Accounting for Packaging Material Thickness: Be sure to consider the thickness of any additional materials like paper liners or protective inserts.

Insufficient Buffer Space: Avoid making the tube too tight. Buffer space is important for easy insertion and removal of the product.

Overlooking Product Weight: Heavier products need sturdier tubes and may require slightly larger dimensions to ensure they don’t get damaged during transport.

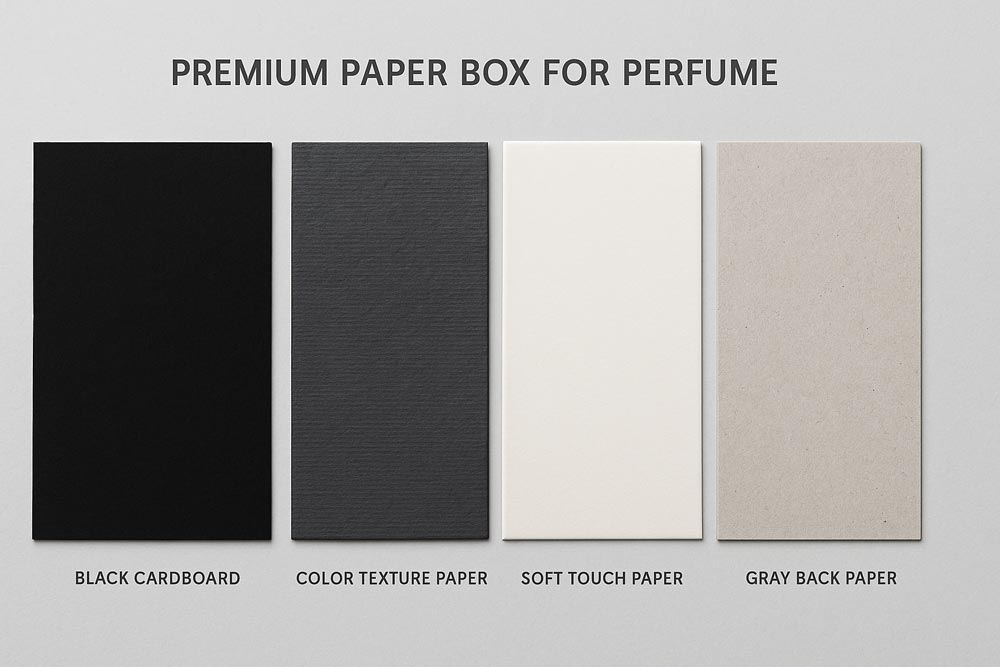

7. Customization Options for Paper Tube Container

Custom paper tube containers offer a variety of customization options. Some of the key elements you can adjust to create the perfect paper tube container for your product include:

Shape: While most custom tubes are round, you can also create oval or square shapes for unique products.

Diameter and Height: These are adjustable based on your product’s dimensions and packaging needs.

Printing and Design: Custom printing allows you to add your logo, branding, or product information to the tube, creating a cohesive look for your product.

Closure Mechanisms: Choose from various lid types such as push-on, screw-on, or snap-fit closures for secure packaging.

8. Frequently Asked Questions About Custom Paper Tube Container Sizing

What dimensions do I need for custom paper tube containers?

Measure your product’s diameter and height, then add buffer space (1 mm for diameter, about 15-18 mm for height).How do I measure my product for paper tube packaging?

Use calipers or a ruler to find the widest part (diameter) and tallest part (height) of your product.What is the standard size range for custom paper tubes?

Sizes can vary widely; typically, diameters range from 15 mm to 230 mm, with heights up to 500 mm more.Can I get a sample before ordering custom paper tubes?

Yes, most manufacturers offer samples to ensure proper sizing before bulk orders.How does the size of the paper tube affect product protection?

A well-sized paper tube container prevents movement and damage during transport, while an ill-fitting tube can lead to breakage or deformation.Are there specific guidelines for sizing tubes for different products?

Yes, different products may have unique requirements based on their shape, weight, and intended use

Conclusion: Get the Right Size for Your Custom Paper Tube

Choosing the right size for your custom paper tube is essential for product protection and customer satisfaction. By following a few simple steps and considering key factors like product shape, material thickness, and intended use, you can ensure your packaging is both functional and aesthetically pleasing. Whether you’re shipping cosmetics, food items, or gifts, the perfect-sized paper tube will not only protect your products but also enhance your brand’s image and reputation.

Wanna to a professional manufacturer who can help guide you through the sizing proces? Contact All Paper Tube Co. here to create the ideal custom paper tube container for your needs.