Paper tube packaging is a type of eco-friendly packaging made primarily from recyclable paper materials, designed in a round shape. Known for its simplicity and versatility, it meets sustainable needs while providing strong protection for various products. This type of packaging is widely used across industries, including food, cosmetics, gifts, and electronics, valued for its elegant appearance and practicality.

Constitution of Custom Paper Tube Packaging

Popular Styles of Paper Tube Packaging

1. Single-Tube Packaging

Single-tube packaging features a one-piece cylindrical structure, with either the top or bottom sealed. The design is simple, functional, and cost-effective, making it one of the most widely used styles. The sealing can be achieved through machine processes for a tamper-proof finish, ensuring basic product protection.

2. Two-Part Tube Packaging (Telescopic Style)

This style includes two components: a lid and a base tube. The lid overlaps and slides over the base tube, creating a snug fit. The telescopic structure allows for convenient opening and closing, while also offering a sleek and professional appearance.

3. Three-Part Tube Packaging (Butted Style)

Three-part packaging consists of a lid, middle tube, and base. The symmetrical design allows for easy access to the product inside while also making it perfect for stacking or displaying. It provides enhanced visual appeal and practicality for items requiring frequent use or display.

4. Other Customizable Styles

Push-Up Design:

Features a bottom mechanism where users push the base to access the product, common for items like lip balms or solid fragrances.

Windowed Design:

Includes a transparent window, often made of plastic or cellulose, to display the product inside. The window can be customized in shape and size to align with branding.

Child-Resistant Design:

Equipped with safety features to prevent accidental opening by children. This is achieved using mechanisms like press-and-turn lids or locking features.

Benefits of Custom Paper Tube Packaging

1. Eco-Friendliness

Paper tube packaging is made mainly from renewable materials like kraft paper, cardboard, and other plant-based fibers. These materials offer several benefits:

Recyclable: They can be easily processed in standard recycling systems, helping to reduce the amount of waste that ends up in landfills.

Biodegradable: Being natural materials, they break down over time, which lessens their environmental impact compared to plastics.

Sustainable: The production methods typically use sustainable forestry and eco-friendly sourcing practices.

This environmentally friendly profile meets the growing consumer demand for green packaging solutions, making paper tube packaging a preferred option for brands that prioritize sustainability.

2. Customizable

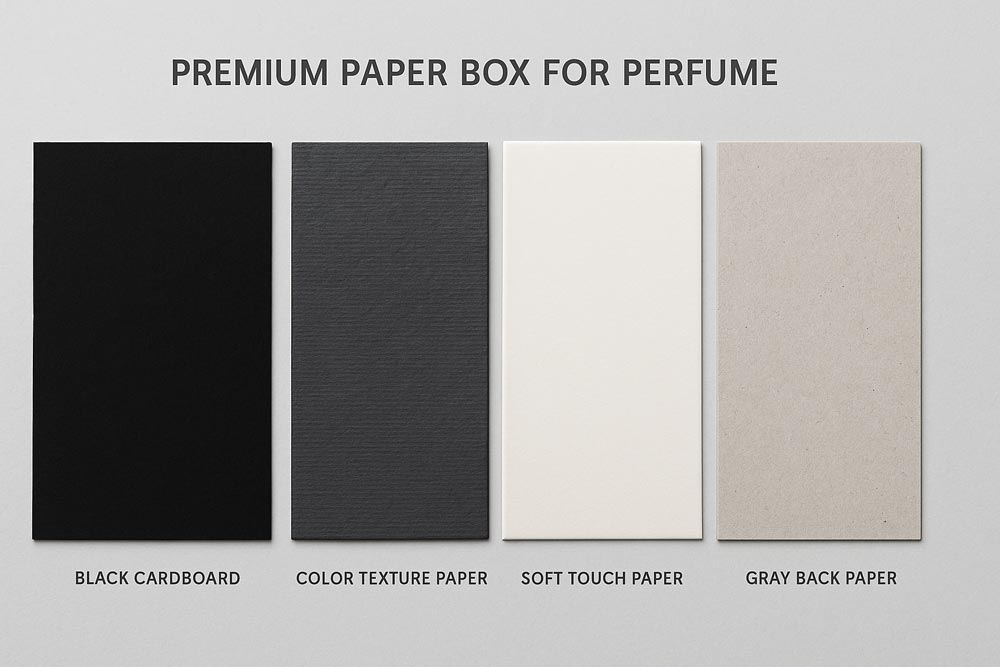

Paper tube packaging provides exceptional versatility in design and personalization. Brands can customize the following elements:

Size and Shape: Choices vary from small tubes for cosmetics to larger containers for industrial products.

Printing Options: Full-color designs, embossing, foil stamping, and matte or glossy finishes can be utilized to create eye-catching products.

Functional Add-Ons: Custom lids, window cutouts, or child-resistant features can be incorporated to address specific needs.

This degree of customization guarantees that packaging aligns with branding goals while also serving practical functions.

3. Brand Enhancement

Paper cylindrical packaging, with its premium look and feel, enhances product presentation significantly. Its sleek lines, smooth surface, and potential for high-end finishes make it perfect for:

Luxury Products: Items like cosmetics, gifts, and gourmet foods gain from its sophisticated appearance.

Differentiation: Distinctive designs enable brands to stand out in crowded markets.

Storytelling: The generous surface area provides space for captivating graphics, text, and branding elements that effectively convey a brand’s identity.

Consumers frequently link cylindrical paper packaging with quality, which boosts the perceived value of the product.

4. Protection

The robust design of custom paper tube packaging provides outstanding protection for various products. Its strength comes from:

Compression Resistance: The round shape evenly spreads pressure, helping to avoid collapse or damage during transportation and handling.

Barrier Options: It can include materials such as aluminum foil lining or PE coating to protect contents from moisture, air, and light.

Shock Absorption: Perfect for fragile or delicate items, as the design reduces the impact of external forces.

This makes it a reliable option for packaging food, cosmetics, and electronics, ensuring that products reach their destination in perfect condition.

Two Core Challenges and Solutions for Paper Tube Packaging

Challenge 1: Cannot Directly Contact Food

Custom paper tube packaging made from paper or cardboard does not provide the necessary barrier properties for direct contact with food. Without appropriate treatment, food products could be at risk of contamination, moisture, or oil absorption.

Solutions:

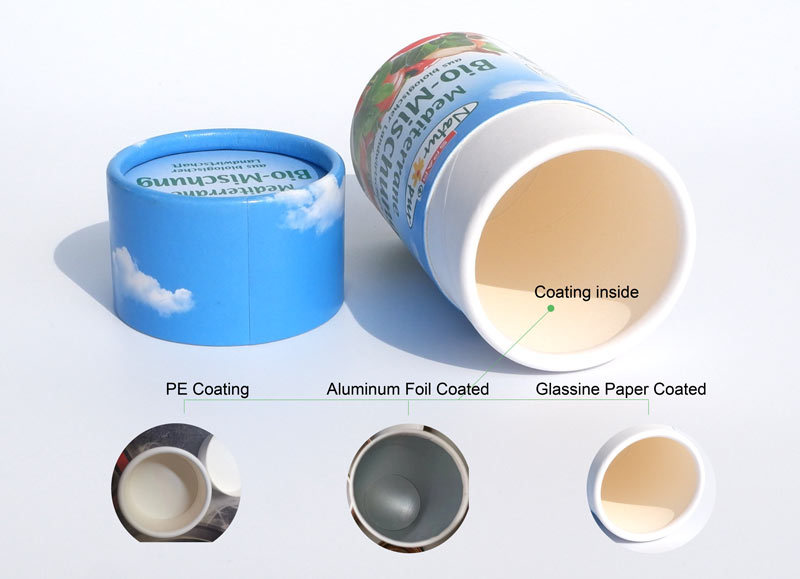

To make paper tube packaging suitable for direct food contact, we must add a food-grade coating to the inner layer of the tube. When customizing cylindrical packaging for food products, we commonly use three types of food-grade coatings, as detailed below:

PE Coating

PE coating is a layer of polyethylene applied to the interior of the tube to create a moisture-resistant barrier.

Advantages:Protects against moisture and oil penetration. Maintains the quality of dry goods like grains and powders.

Applications: Best for packaging dry items such as spices, cereals, or flour.

Disadvantage: May impact recyclability unless used with advanced recycling processes.

Food-Grade Aluminum Lining

Aluminum lining is a thin aluminum foil lining adds superior moisture and oxygen resistance.

Advantages:Provides excellent protection against spoilage. Extends shelf life for sensitive products.

Applications: Ideal for coffee, powdered milk, and premium spices.

Disadvantage: Higher cost compared to other linings.

Glassin Paper Lining

Glassin paper ling is a smooth, grease-resistant paper used for lining.

Advantages:Naturally oil-resistant and eco-friendly. Lightweight and biodegradable.

Applications: Perfect for oily snacks, confectioneries, and nuts.

Disadvantage: Limited resistance to moisture and air compared to aluminum lining.

Challenge 2: Limited Sealing Capability

Custom paper tube packaging is not inherently airtight, which can lead to exposure to air, moisture, or contaminants, affecting product freshness.

Solutions:

By applying food-safe lining materials and innovative sealing methods, paper tube packaging can address its main challenges to comply with food-grade standards. These improvements not only boost product safety but also preserve the packaging’s environmentally friendly and customizable qualities, positioning it as a leading option in contemporary sustainable packaging solutions.

Machine-Sealing

This process uses machinery to secure the top and bottom of the tube for a tight seal.

Advantages:Ensures a tamper-proof, airtight finish. Ideal for high-moisture or oxygen-sensitive products.

Applications: Best for food packaging, especially for coffee or powdered foods.

Disadvantage: Requires specialized equipment, increasing production costs.

Barrier Enhancements Inner Lids

Provides an additional layer between the product and the external environment.

Applications: Suitable for tea, spices, or other dry goods requiring extra protection.

Disadvantage: Cannot provide as good airtightness as machine sealed ones, better not to store for long time.

Sealing Films

A thin, heat-sealed film covers the product before placing the outer lid.

Advantages: Adds moisture and tamper resistance without compromising design.

Applications: Commonly used for cereals, nuts, and confectionery.

Disadvantage: Adds complexity to the packaging process.

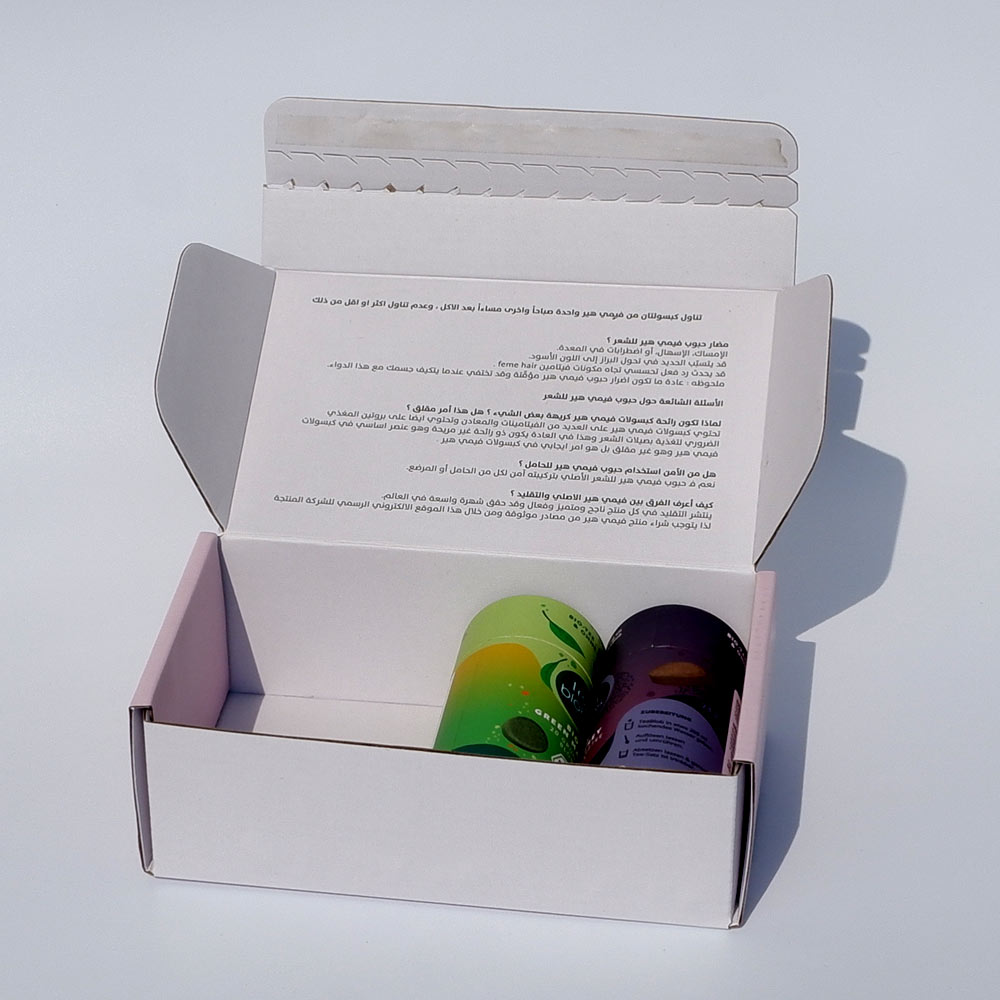

Applications of Custom Paper Tube Packaging

- Food Industry: Ideal for tea, coffee, nuts, spices, and more.

- Cosmetics Industry: Used for lip balm, skincare products, and perfumes.

- Gift Industry: Perfect for crafts, jewelry, and candles.

- Electronics: Suitable for small gadgets like headphones and power banks.

Conclusion

Paper tube packaging has emerged as a leading choice in various industries due to its eco-friendliness, versatility, and premium appearance. If you’re in search of an innovative and sustainable packaging solution, consider contacting All Paper Tube Co. for high-quality, customizable paper tube options tailored to your brand’s specific requirements. We provide competitive pricing, expert advice, and a strong commitment to sustainability.

Contact us to custom your paper tube packaging

FAQs

How Can Paper Tubes Be Made Moisture-Resistant?

Standard paper tubes are not moisture-resistant, as paper inherently lacks this property. To improve moisture resistance, an inner lining must be added. The three common materials used for this purpose include:

- PE Coating: Offers basic moisture and oil resistance.

- Aluminum Lining: Provides the best moisture barrier and is ideal for products requiring high protection.

- Glassine Paper: Known for oil resistance, offering moderate moisture protection.

Among these, aluminum lining stands out for its superior moisture resistance.

How Can I Customize 100% Biodegradable Paper Tubes?

For 100% biodegradability, all materials must be made from paper or other biodegradable substances. Here’s how to achieve this:

- Use uncoated paper for the inner lining or opt for biodegradable glassine paper.

- Replace traditional printing laminations with an oil-based coating for print protection.

These steps ensure the entire packaging is compostable and eco-friendly.

How Do I Design My Paper Tube Packaging?

To create attractive and effective designs:

- Opt for a thoughtful and appealing design that aligns with your branding.

- Use premium printing finishes such as foil stamping, UV coating, and Pantone color printing to enhance visual appeal.

- We provide blank design templates upon request for easy customization.

Which Sealing Machines Should I Use for My Paper Tubes?

We recommend two cost-effective sealing machines for different applications. Details about these machines can be foun here.

Does a Windowed Paper Tube Retain Its Sealing Properties?

While windowed paper tubes provide a great way to showcase the contents, their sealing capability is reduced compared to non-windowed tubes.

- The window section uses PVC plastic film adhered to the opening, which may have microscopic gaps.

- While not entirely airtight, it still offers moderate protection depending on the adhesive quality.

For better sealing with windowed designs, additional protective barriers might be necessary.