Achieving perfect paper tube color matching is one of the biggest challenges in packaging design. The frustration of receiving a production run that doesn’t match your vision is a common but avoidable problem. This comprehensive guide breaks down the professional process to ensure your paper tube packaging colors are accurate from screen to shelf.

The Root of Color Mismatches: Why Paper Tube Packaging is Vulnerable

Achieving precise paper tube color matching requires understanding where things go wrong. The journey from a bright, backlit RGB screen to physical ink on paper is fraught with variables. The most significant factors are:

Device Discrepancies: Every monitor and printing press has a unique color gamut and calibration.

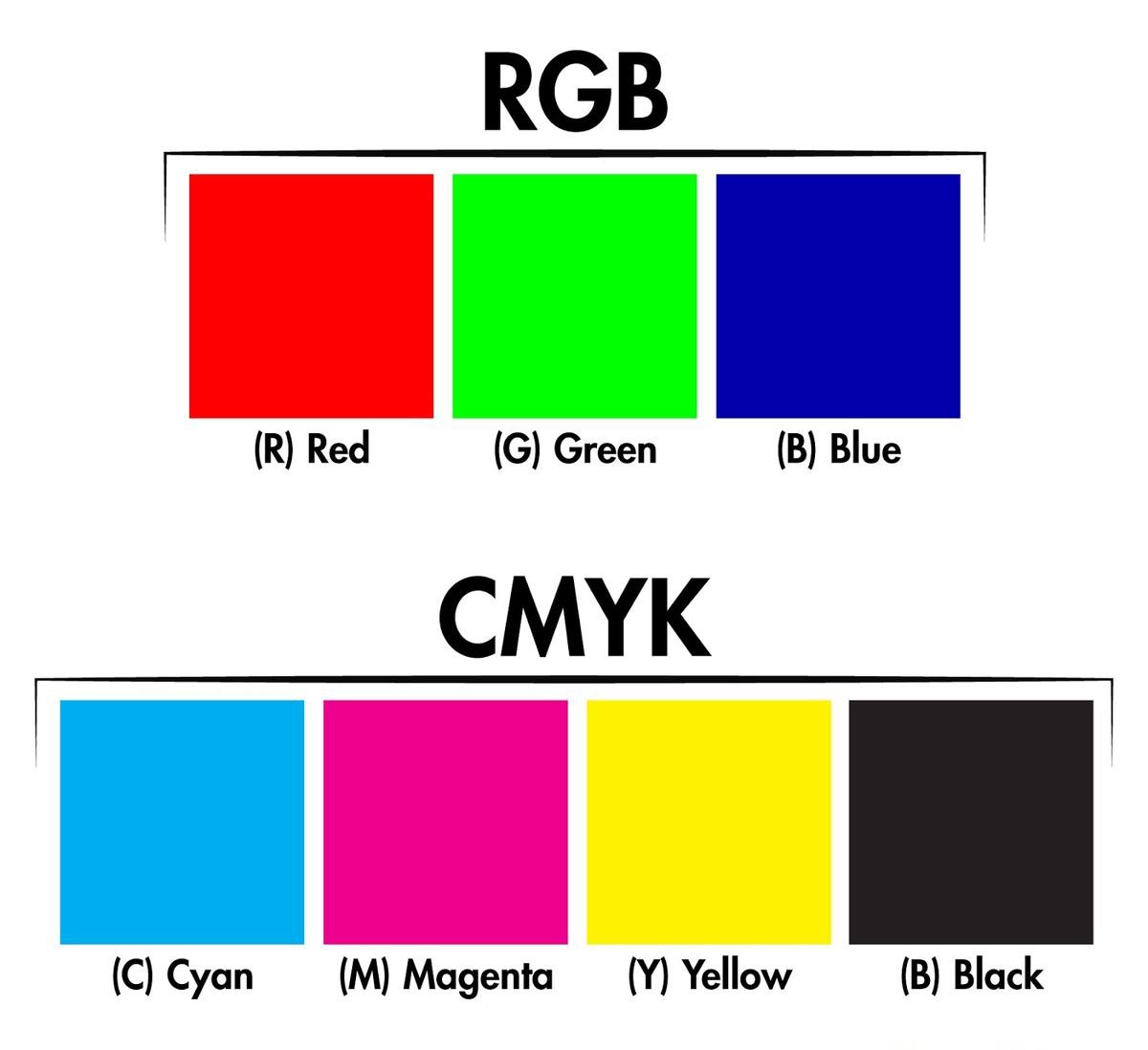

Incorrect Color Models: Using RGB (for screens) instead of CMYK (for print) is a primary cause of massive color shifts.

The Substrate’s Role: The paper material itself is a critical variable. The same ink will look vibrant on smooth, coated art paper but appear significantly duller and darker on porous, uncoated kraft paper due to ink absorption. Ignoring the substrate makes consistent paper tube color matching impossible.

Design Foundation: Building the Right Color Framework for Paper Tube Packaging

A reliable paper tube color matching process starts with standardized design practices.

Mandate CMYK Mode: From the moment you create a new document, it must be set to CMYK color mode. This is non-negotiable, as it aligns your design workspace with the printing process.

Standardize Spot Color Selection: When using Pantone colors, you must match the Pantone book series to your target paper.

Use Pantone COATED guide colors for glossy or coated paper tubes.

Use Pantone UNCOATED guide colors for uncoated or kraft paper tubes.

Applying an “Uncoated” code code to a coated surface (or vice-versa) will result in a visible color difference, a common but serious paper tube color matching error.

Verify Color Guide Versions: Ensure you and your manufacturer are using the same physical edition of the Pantone guide. Pantone updates its guides periodically, and even minor changes can impact paper tube color matching across production batches.

Proofing Standards: The Make-or-Break Stage for Paper Tube Color Matching

The proofing stage is your last and most critical checkpoint for accurate paper tube color matching.

Insist on Press-Production Proofs: For color-critical work, you must request a press proof. This proof is run on the actual production press, using the exact inks and paper tube material planned for the full order. It is the gold standard for paper tube color matching.

Understand the Limits of Digital Proofs: A digital proof (from an inkjet or laser printer) is suitable only for checking layout and content. It must not be used as a color contract standard. The imaging technology is fundamentally different from the offset or flexo printing used for mass production, and colors will not match.

Professional Collaboration: Building a Color Standard with Your Paper Tube Manufacturer

Perfect paper tube color matching is a collaborative effort between you and your manufacturer.

Establish Material Standards: At the project’s outset, ask your paper tube packaging supplier for their physical print samples and color guides. A specialized manufacturer like Allpapertube provides clients with substrate-specific color references, offering crucial support for your paper tube color matching decisions.

Provide Authoritative References: Supply your manufacturer with the specific, agreed-upon Pantone numbers and a signed physical reference, if available.

Issue Clear Instructions: In your technical files, explicitly state which colors are CMYK and which are spot colors, eliminating ambiguity at the source.

Final Verification: The Ultimate Color Judgment Under Standard Light

No matter how well-calibrated your screen or how precise your files, the human eye under consistent lighting is the final judge.

Always compare the final press proof against your standard Pantone guide in a standard light booth (D50 is industry standard). This step, which accounts for the final paper material, is the non-negotiable final gatekeeper for achieving flawless paper tube color matching and ensuring your bulk production meets expectations.