When sourcing custom cardboard tubes, smart buyers recognize that understanding the pricing structure, minimum order requirements, and production timeline is crucial for budget planning and project success. Whether you’re exploring custom cardboard tube packaging for food products, cosmetics, or industrial applications, having clear insights into these key factors helps you make informed decisions. The reality of manufacturing custom cardboard tubes involves multiple production stages, each contributing to the final cost and timeline. This comprehensive guide provides transparent information to help you navigate the process efficiently, whether you need small quantities for market testing or large volumes for product launches.

What Really Determines the Cost of Custom Cardboard Tubes?

The pricing of custom cardboard tubes isn’t arbitrary—it reflects the complexity of manufacturing processes and material requirements. Several key factors directly impact your final investment in custom cardboard tube packaging:

Material selection represents your first major cost decision. Standard kraft paper offers the most economical solution, while premium options like white coil board or FSC-certified papers with recycled content increase costs by 15-30%. The paper thickness (ranging from 0.88mm to 1.2mm) further influences material expenses, with thicker walls providing greater durability at higher cost.

Production processes contribute significantly to your overall investment. Each manufacturing stage—printing setup, tube winding, and any secondary operations like die-cutting or window punching—incurs separate setup charges. This explains why custom cardboard tubes with multiple design variations cost more per unit, as each change requires machine adjustments and increases material waste during production changeovers.

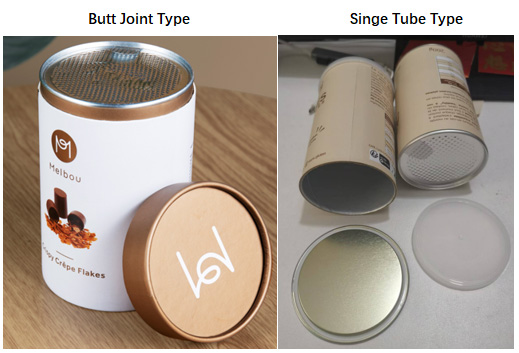

Tooling requirements vary by project complexity. While manufacturers typically maintain comprehensive tooling for standard cylindrical custom cardboard tubes, unique shapes or specialized end closures may require custom tooling development. Fortunately, most projects can utilize existing tooling, keeping this cost component manageable for standard configurations.

Making Sense of Minimum Order Quantities (MOQs)

Minimum Order Quantities exist for practical manufacturing reasons that directly affect cost efficiency in custom cardboard tube production:

The manufacturing reality is that producing custom cardboard tubes involves multiple specialized processes, each with setup requirements that make very small quantities economically challenging. This explains why MOQs typically start at 500 units for digitally printed tubes and 2,000-5,000 units for traditionally printed versions requiring plate creation.

For businesses needing smaller quantities, strategic approaches can help manage costs. Consolidating design variations, using standard tube sizes, and selecting digital printing for shorter runs all contribute to more accessible entry points for custom cardboard tube packaging projects.

The Real Timeline: From Design to Delivery

Understanding the production sequence helps set realistic expectations for your custom cardboard tube project:

The sampling phase typically requires 3-5 business days, serving as a crucial quality checkpoint before full production. This stage uses the same manufacturing processes as mass production, ensuring your final custom cardboard tubes will match the approved samples in quality and specification.

Mass production generally completes within 15 working days, encompassing three primary phases: printing and ink drying, tube winding and adhesive curing, plus any secondary processing like special finishes or assembly operations. This timeline can extend for complex projects involving multiple special finishes or unique structural elements.

Logistics options provide flexibility for your schedule, with express shipping delivering in 4-7 days, air freight requiring 10-12 days, and sea freight taking 25-40 days depending on destination. European destinations typically reach 40 days for sea freight, making this the most economical but slowest option for custom cardboard tube packaging shipments.

Case Study: Real-World Cost and Timeline Analysis

Consider NUWA chocolate who needed custom cardboard tubes for their premium tea line. Their specifications included 60mm diameter × 200mm height tubes with 4-color printing and foil stamping on white coil board, with metal ends and foil liners. For 3,000 units, their cost breakdown included approximately 40% for materials, 25% for printing and finishing, 20% for tooling and setup, and 15% for assembly and quality control. Their project completed within the standard 18-day production timeline plus 10 days for air freight delivery, demonstrating typical scheduling for mid-volume custom cardboard tube orders.

Optimizing Your Custom Cardboard Tube Investment

Strategic planning significantly enhances the value of your custom cardboard tube packaging investment. Consider consolidating orders to maximize quantity discounts and minimize per-unit costs. Planning around standard tooling availability can reduce both costs and lead times. Additionally, aligning production schedules with your marketing calendar ensures timely product launches while potentially avoiding peak season surcharges.

Ready for Your Transparent Custom Cardboard Tube Quote?

At Allpapertube Packaging, we believe in complete transparency for custom cardboard tube projects. Our expertise helps clients navigate cost structures, quantity requirements, and production schedules to find optimal solutions for their specific needs and budgets.

Contact us today with your project specifications to receive a comprehensive quotation for your custom cardboard tubes within 24 hours.