When it comes to eco-friendly packaging, paper tube containers have become a go-to choice for brands in cosmetics, food, health, and more. But to ensure freshness, safety, and functionality, choosing the right paper tube sealing machine is essential. Whether you’re launching a new product or scaling up production, this guide will help you understand the sealing options available and how to determine machine compatibility with your packaging.

Why Sealing Matters for Paper Tube Packaging

Sealing isn’t just a finishing step — it’s a vital part of maintaining product integrity. A reliable paper tube sealing machine prevents contamination, extends shelf life, and protects against moisture, especially for powders, teas, herbs, or cosmetics.

Because paper tube packaging often consists of all-paper materials with a protective lining, not every sealing method works. That’s why it’s important to match your sealing approach with the specific construction of your paper tube.

Common Types of Sealing Machines for Paper Tubes

1. Manual Can Sealer

Use case: Perfect for small-batch or hand-filled paper tubes.

Pros: Low cost, easy to operate, portable.

Cons: Slower, labor-intensive, harder to ensure consistent results.

Tip: Great for handmade brands or startups.

2. Semi-Automatic Can Sealer

Use case: Small to mid-size businesses needing higher speed.

Pros: Improves sealing speed and consistency while still affordable.

Cons: Requires some manual operation.

Tip: A balanced choice between cost and efficiency.

This machine is a go-to paper tube sealing machine for cylindrical paper canisters used in dry food packaging.

3. Fully Automatic Can Sealer

Use case: High-volume production lines.

Pros: Fast, efficient, and consistent for bulk production.

Cons: Expensive and larger footprint.

Tip: Ideal for factories or contract packers.

4. Heat Sealing Machine (Custom Adaptation)

Use case: Brands needing a stronger air-tight seal inside the tube.

Important: Paper tubes themselves can’t be sealed with heat unless their inner surface is coated with PE or PP film (also known as lamination).

How it works: A pre-cut aluminum heat-seal membrane is placed inside the paper tube. When the inner wall has PE lamination, the aluminum membrane can bond using heat.

Pros: Strong barrier against moisture and oxygen.

Cons: Requires laminated inner wall + custom-fit sealing heads.

What About Automatic Induction Sealers?

An induction sealing machine uses electromagnetic waves to seal plastic or foil-lined caps onto plastic bottles. While high-speed and efficient, it’s not compatible with paper tube packaging unless the container is rigid plastic or metal.

❌ Not recommended for paper-based tubes without metal caps

❌ No pressure ring means foil cannot adhere to paper

If your customer uses an induction system, it’s important to explain that a paper tube sealing machine is a different category altogether.

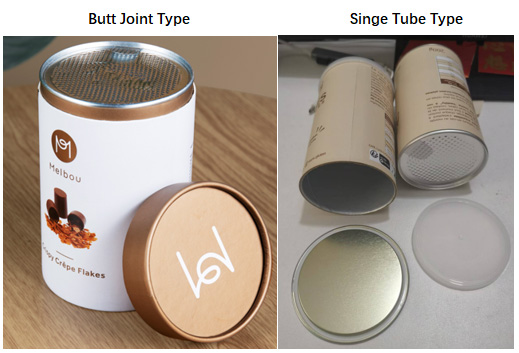

How to Know Which Paper Tube Sealing Machine Fits

Before choosing any machine, consider:

| Criteria | What to Check |

|---|---|

| Tube Liner | Is there PE, foil, or PLA coating inside? This affects adhesion. |

| Tube Thickness | Can the machine handle rigid cardboard walls? |

| Production Scale | Manual or semi-auto for small runs, full-auto for high volume. |

| Seal Type | Tear-off foil? Pull-tab lid? Heat-reactive film? |

| Container Shape | Cylindrical tubes seal best; irregular shapes need custom tooling. |

Need help matching your packaging to a sealing method? At All Paper Tube Co., we assist clients in choosing the right paper tube sealing machine setup for their production goals.

Real Example: Paper Tube with Aluminum Tear Lid

One of our recent clients packaged powdered herbs in a kraft paper tube with a tear-off aluminum seal. We helped them select a pressure-sealing machine with a custom die-cut lid mold, achieving both a food-safe barrier and a fully recyclable exterior. The result? A tamper-proof package that aligned with their zero-waste branding.

Final Tips for Paper Tube Sealing

The best sealing solution for paper tube packaging remains the mechanical can sealer + aluminum lid.

Want stronger protection? Use PE-laminated paper tubes + heat-seal membranes.

Not all sealing machines are universal. Check your customer’s machine type and give technical specs in advance.

Always do a sealing test before bulk production.

Need help choosing the right lid or laminated tube structure? All Paper Tube Co. can help you design the right paper tube for sealing, complete with test-ready samples and professional advice.

Learn more at www.allpapertube.com