Custom paper tube packaging is a versatile and stylish solution for various products, from cosmetics to gifts. Whether you’re looking to protect your product or simply enhance its presentation, choosing the right packaging structure is crucial. Here’s a quick guide to help you navigate the process of customizing your paper tube packaging.

1. Determine the Purpose of the Custom Paper Tube Packaging

The first step in customizing your paper tube is to define its intended use. Are you packaging food, cosmetics, gifts, or electronic products? Different uses will dictate the choice of packaging structure and materials.

2. Choose the Custom Paper Tube Style

When selecting a packaging structure, consider whether your product requires a sealed or non-sealed solution.

Airtight Sealed Tubes

A sealed paper tube must be sealed by equipment requested, and there’s only a tube style can be easy with this operation, that’s paper canister, see picture below.

Non-Sealed Tubes

Non-sealed custom paper tubes can be customized in many styles, and with many personalized customizations. They’re widely used for products that don’t require heavy protection, offen used for beverage & spirits, apparel, gifts, houshold products, electronics.

3. Choose the Right Materials

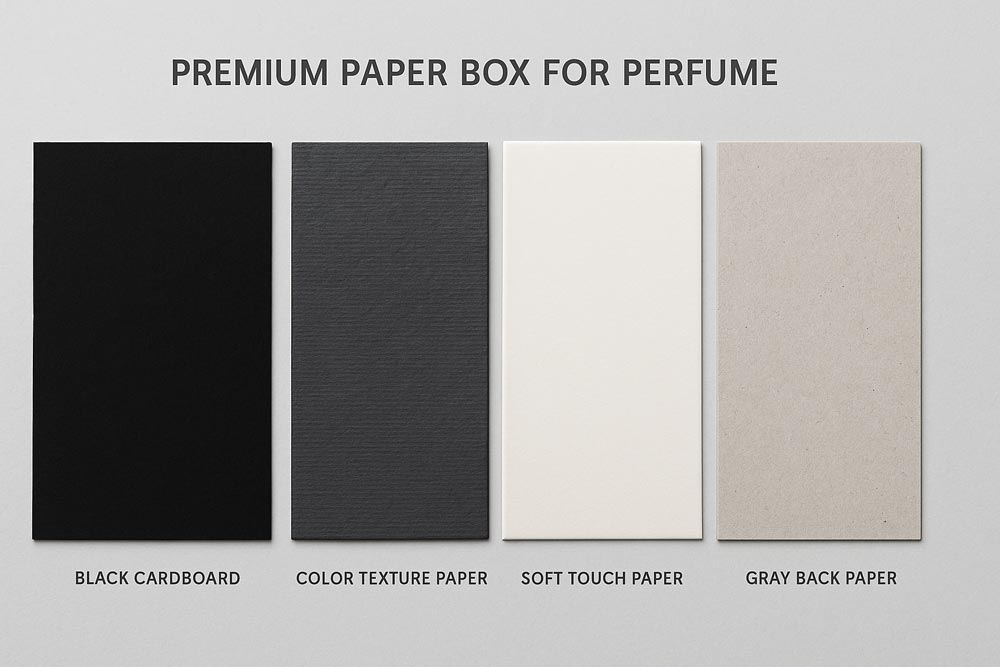

Selecting the appropriate paper material is essential for both functionality and brand presentation:

- Kraft Paper: Eco-friendly and natural, ideal for brands focused on sustainability. There are black, white and brown colors to choose from.

- Coated Paper: Emphasizes an environmental focus, suitable for gift and electronic packaging.

- Specialty Paper: Specialty papers are high-quality papers designed for specific applications, featuring unique textures, finishes, or coatings. They are used in premium custom paper tube packaging, invitations, labels, and artistic projects to enhance visual appeal and functionality.

Kraft Papers

Coated Paper

Specialty Papers

4. Design and Printing on Custom Paper Tubes

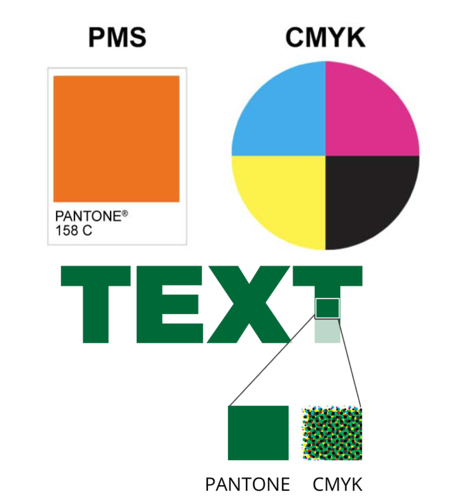

Your design should reflect your brand and product. Printing options include:

- CMYK Printing: It’s the standard for printing full-color images, like photos and brochures. It works by layering these inks in different proportions to produce various colors, making it versatile for various types of print jobs, and it is more cost-effective than using multiple spot colors.

- Pantone PMS Printing: PMS print produces consistent and accurate color reproduction. It’s ideal for ensuring that your brand’s colors are consistent and true to your identity. If you have specific brand colors that must be exact, spot color printing is the way to go.

5. Choose Printing Techniques

Enhance your custom paper tube packaging with various printing techniques:

- Foil Stamping: Adds a high-end feel for your paper tube packaging, often used for premium products.

- UV Spot Gloss: Highlights specific design elements, drawing attention to key features.

- Embossing/Debossing: Adds texture and a tactile quality to the packaging.

Foiling

UV Gloss

Embossing

6. Custom Paper Tube Sample Proofing

Before proceeding with full production on custom paper tube packaging, it’s wise to create a sample proof. This allows you to verify dimensions, structure, color accuracy, and overall print quality, reducing the risk of errors in mass production.

Custom paper tube samples will cost 5-6days on production, the labels on outer surface can be handled by digital printing or offset printing, everything will be confirmed and get approval by clients before start.

7. Confirm Production Timeline and Quantity

Finalize your production schedule and order quantity based on your needs. Generally, custom paper tube packaging production for bulk orders takes 2-3 weeks, with larger quantities leading to lower per-unit costs.

Tips:

- Simplify Design: A cleaner design often reduces production complexity and highlights your brand more effectively.

- Consider Eco-Friendly Materials: Using sustainable materials not only aligns with current trends but also appeals to environmentally conscious consumers.

- Maintain Clear Communication: Work closely with your supplier to ensure every detail is accurate and production proceeds smoothly.

By following these steps, you can quickly and efficiently customize paper tube packaging that meets your needs and enhances your product’s presentation.