Custom paper tube packaging is more than just a protective container for your product—it’s an extension of your brand. The printing techniques and design choices you make can significantly impact how your product is perceived. Whether you’re aiming for a minimalist look or a bold, vibrant design, understanding the right printing methods and tips can help you create packaging that truly stands out. In this blog, we’ll explore various printing techniques, share practical tips for achieving high-quality prints, and discuss how to avoid common pitfalls.

1. Understanding Printing Techniques

In our custom paper tube design printing process, we typically use two types of printing methods: 1) offset printing and 2) digital printing. Within offset printing, we further categorize it into spot color printing and four-color process printing to meet different printing needs.

Offset Printing

An offset press uses printing plates but does not transfer ink directly from the printing plate to the paper. The ink on a printing plate is first transferred to a rubber cylinder, which then transfers the ink to the paper. The ink application being “offset” rather than transferring directly to the paper is the reason this printing method is called Offset Printing.

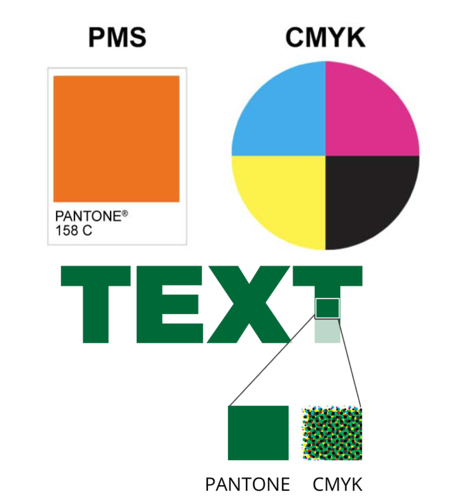

Offset printing uses two main color systems to produce high-quality images…the CMYK Process and PMS colors. This article explains the difference between these two color systems.

Spot Color (PMS) Printing

Spot color printing is often referred to as PMS (Pantone Matching System) printing. It uses pre-mixed inks used in the Pantone Matching System to produce consistent and accurate color reproduction. It’s ideal for ensuring that your brand’s colors are consistent and true to your identity. If you have specific brand colors that must be exact, spot color printing is the way to go.

Additionally, for full template or large areas of color printing, such as when the background color of our custom paper tube design is a single solid color, we should use spot color printing to avoid issues with uneven color distribution, commonly known as color inconsistency or “mottling.”

CMYK 4-color Printing

CMYK printing is a color process that uses four inks—Cyan (C), Magenta (M), Yellow (Y), and Black (K)—to create a wide range of colors. It’s the standard for printing full-color images, like photos and brochures. CMYK works by layering these inks in different proportions to produce various colors, making it versatile for various types of print jobs, and it is more cost-effective than using multiple spot colors.

While it’s versatile and cost-effective for general printing, it may struggle with precise color matching or vibrant hues compared to spot color (PMS) printing. It’s unavoidable when printing our custom paper tube design in this way, we can’t have our cake and eat it to.

Digital Printing

Digital printing is perfect for short runs and personalized designs. It’s cost-effective for smaller batches and allows for more flexibility in design changes. If you’re experimenting with different designs or need a quick turnaround, digital printing is your best bet.

While pls be noted that for digital printing, we must ensure our artwork resolution is at least 300 DPI (dots per inch). This ensures that images and graphics print clearly and sharply without pixelation.

When custom paper tube samples, digital printing is the most efficient way, not only can save cost but also save time. While same as to CMYK printing, the main drawback of digital printing is that color consistency can be less stable and precise compared to PMS (spot color) printing.

General Tips

In our custom paper tube process, we use different printing methods based on the customer’s product requirements.

Sample Printing

Digital printing is used for paper tube samples print, which aim to confirm packaging structure, dimensions, and information accuracy, as it saves both time and costs for the customer. While special requirements are handled on a case-by-case basis.

Bulk Order Printing

For large production runs, we must use offset printing, and would provide recommendations for either spot color or four-color process printing based on the design elements provided by customers.

2. Tips for Achieving High-Quality Printing

Once you’ve chosen your printing technique, here’s how to ensure the best results on the custom paper tube printing:

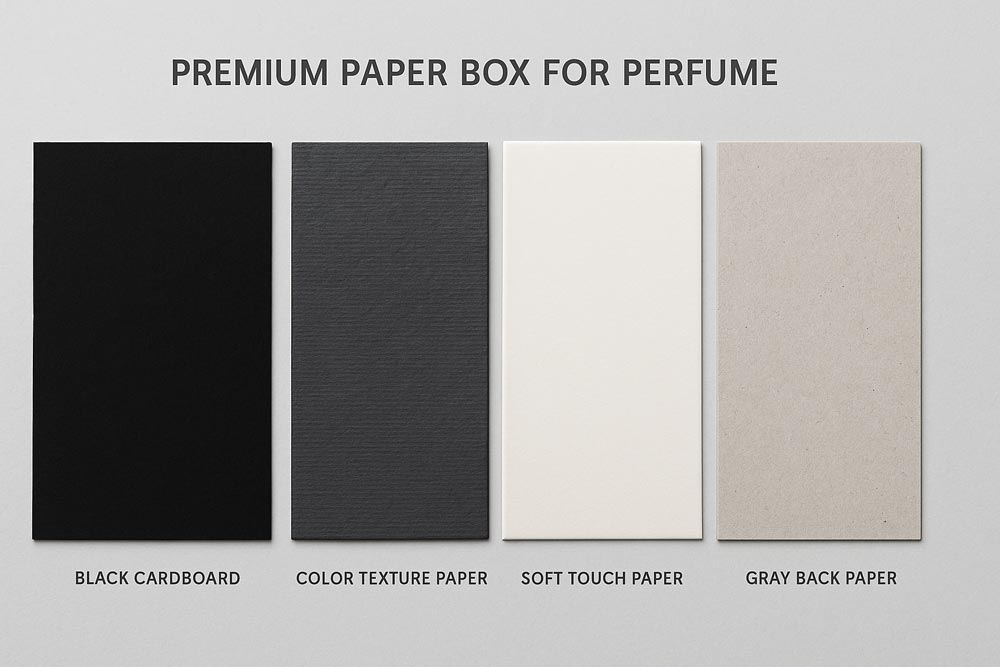

Choosing the Right Paper Material

The paper material you select plays a significant role in the final print quality. For example, kraft paper gives a rustic, natural look, while coated paper offers a smooth, glossy finish. Make sure to choose a paper type that complements your design and product. We can learn about the paper material options from this page.

Resolution and Image Quality

High-resolution images are crucial to avoid pixelation. Ensure your artwork is prepared at a minimum of 300 DPI (dots per inch) for crisp, clear prints. This is especially important for intricate designs or detailed images.

High-resolution images can be used for sample digital printing; however, for large-scale production of custom paper tubes, we require vector files, as high-resolution images alone are not sufficient. If needed, we will provide you with die-cut templates to assist you in filling out your design.

Color Consistency

Maintaining color consistency is vital for brand recognition. Use color profiles and proofs to ensure that what you see on the screen matches what will be printed. Request print proofs to check for any color discrepancies before the final run.

Design Considerations

When designing for print, keep it simple. Avoid overly intricate details that may not reproduce well. Instead, focus on clean lines, balanced patterns, and strategic use of negative space to ensure your design prints clearly and looks professional.

3. Enhancing Your Packaging with Finishing Techniques

Beyond basic printing, consider these finishing techniques to add extra flair to your packaging:

Foil Stamping

Foil stamping adds a touch of luxury by applying a metallic finish to certain elements of your design, such as logos or text. It’s an excellent choice for creating a premium look and feel. And it’s highly suggested on a custom paper tube packaging made of kraft paper, which is rough surface and not good for ink print.

Embossing and Debossing

Embossing raises parts of the design on custom paper tube packaging, while debossing impresses it into the surface, adding texture and depth. These techniques work well for highlighting specific elements like your brand name or logo, making your packaging more tactile and visually appealing.

UV Spot Printing

UV spot printing applies a glossy finish to specific areas of our custom paper tube design, creating contrast with the rest of the packaging. This technique is perfect for highlighting important details or adding a subtle, eye-catching effect.

4. Common Pitfalls to Avoid

Even the best designs can falter without attention to detail. Here are some pitfalls to avoid:

Overcomplicating the Design

While creativity is important, avoid overcomplicating your design with too many elements. Simplicity often leads to a more impactful and visually pleasing result.

Ignoring the Bleed Area

The bleed area is the space beyond the trim edge where your design can extend. Ensure you include this in your design files to avoid any unwanted white edges when the packaging is cut to size.

You can ask a blank layout from our packaging specialist for your custom paper tube packaging design, which will show you areas where to print, and where to cut off, we will help you don’t worry.

5. Case Studies and Real-World Examples

Brand Highlight

Consider a brand that used foil stamping and embossing on their paper tube packaging. The luxurious finish helped them stand out in a crowded market, and the tactile elements enhanced the customer’s unboxing experience, reinforcing the brand’s premium positioning.

Conclusion

Printing on custom paper tube packaging is a craft that combines creativity with technical expertise. By selecting the right printing techniques, following practical tips, and avoiding common pitfalls, you can create packaging that not only protects your product but also elevates your brand. Whether you’re looking to make a bold statement or create a subtle, luxurious feel, the right approach to printing can make all the difference. Apply these tips to your next project and watch your packaging come to life.