As eco-friendly beauty packaging becomes the norm, more brands are turning to paper lip balm tubes as a plastic-free, biodegradable alternative. But with a shift in material comes new production challenges—particularly in the areas of filling and sealing. If you’re wondering how to fill paper lip balm tubes without causing leaks, waste, or structural issues, you’re in the right place.

How to Fill Lip Balm Tubes

In this guide, we’ll cover best practices for both small-batch makers and large-scale manufacturers, sharing expert-level how to fill lip balm tubes and sealing tips to ensure your packaging performs as beautifully as it looks.

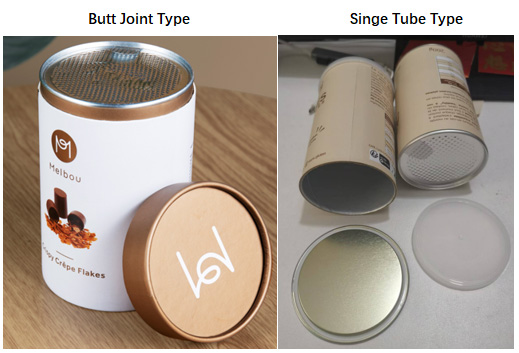

1. Understanding the Structure of a Paper Lip Balm Tube

Paper lip balm tubes are typically composed of:

An outer paper shell (often custom-printed)

An inner waxed, PLA, or oil-resistant liner

A base push-up or twist-up mechanism

Because the inner barrier is essential to keeping the balm from soaking into the paper, maintaining its integrity during filling is key. That’s why understanding how to fill paper lip balm tubes types properly starts with knowing your material.

2. Temperature Matters: Recommended Pouring Range

One of the most common causes of leakage in paper lip balm tubes is overheating the balm mixture. Excess heat can:

Soften or deform the wax or PLA liner

Weaken glue joints in the paper seams

Cause oils to soak into the paper wall

✅ Recommended pouring temperature: 60°C–70°C (140°F–158°F)

This range ensures the balm is liquid enough to pour while staying gentle on the packaging.

💡 Pro tip: Always test your exact formula in a sample tube before full-scale filling.

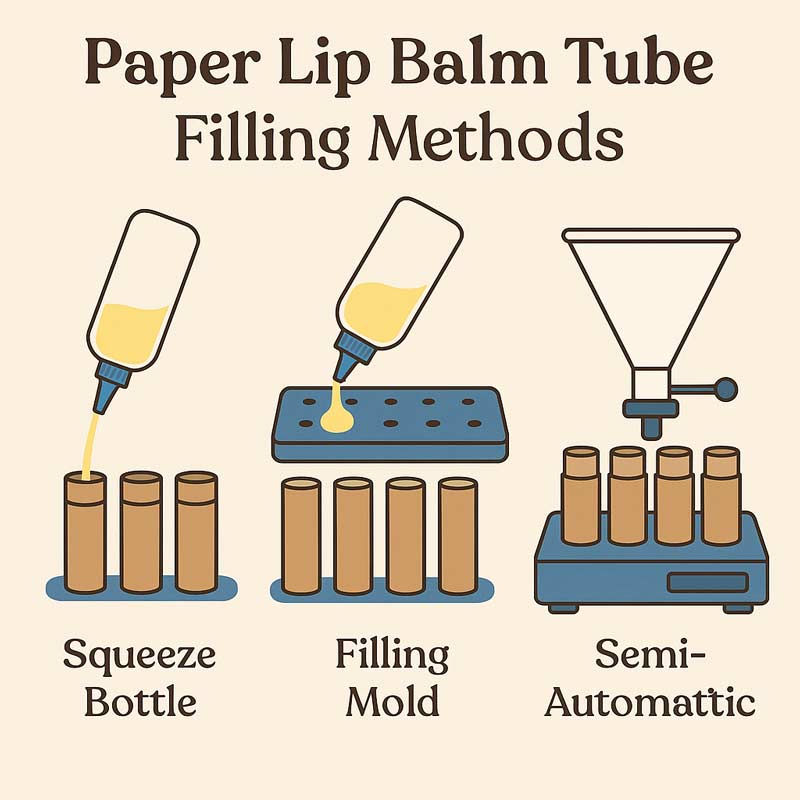

3. Filling Methods: Manual vs. Automated

A variety of tools and techniques exist depending on your production size and resources. Here’s how to fill paper lip balm tubes efficiently:

🖐 For Small-Batch Makers (Handcrafted or DIY Brands):

Use a squeeze bottle, dropper, or beaker with spout to slowly fill each tube

Keep the tube upright using a silicone or cardboard tray

Pour to just below the rim to avoid spillage during cooling

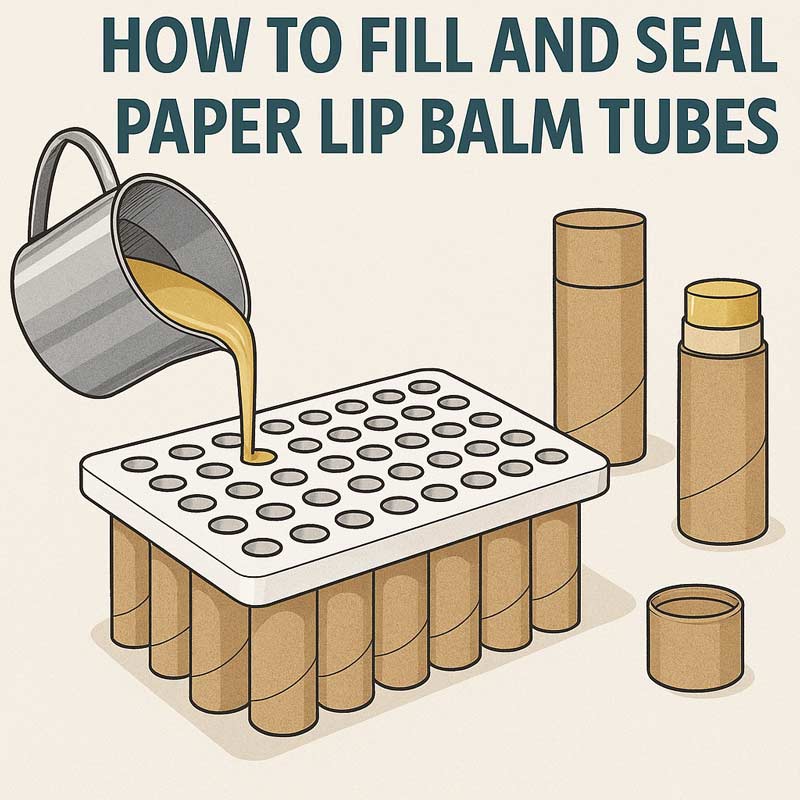

🧩 Filling Mold Boards (Small-to-Medium Scale)

Use a customized plastic filling mold board placed on top of the tubes. Each board has 50–100 holes designed to match the tube diameter.

Insert each paper lip balm tube into a hole from below—the board holds them upright and secure.

Pour the melted balm across the surface of the board—the liquid flows evenly into all tubes through the holes.

This method allows simultaneous filling of multiple units, significantly increasing efficiency for small businesses.

💡 Mold boards reduce manual labor, prevent mess, and can be easily cleaned and reused.

⚙️ For Medium to Large-Scale Production:

Consider a semi-automatic liquid filling machine with heat control

Fill tubes on a tray system that holds them upright and aligned

Clean nozzles regularly to prevent buildup and uneven fills

Knowing how to fill paper lip balm tube styles manually or by machine can reduce product loss and maximize efficiency.

Paper Lip Balm Tubes Filling Methods

4. How to Avoid Leakage and Overflow

Even when the balm is poured correctly, problems can occur during the cooling process:

✅ Tips to prevent overflow and leakage:

-

Don’t fill too full: Leave 1–2 mm at the top

-

Let tubes cool upright at room temperature before capping

-

Avoid sudden temperature shifts that can cause condensation or liner stress

-

Use barrier trays or line cartons with parchment during transport

These practical how to fill paper lip balm tube and sealing tips help maintain the tube’s appearance and prevent oil rings or bulging.

5. Sealing Options: Manual and Scalable Solutions

Once filled and cooled, sealing your tubes protects the balm from contamination and enhances shelf appeal.

🏷️ Manual Sealing:

Use kraft or PET security stickers across the cap

Apply paper tamper bands or branded paper wraps

🔄 OEM/Wholesale Sealing:

Heat-seal paper sleeves or shrink bands using a heat tunnel

Add a wax seal or foil tab for a premium unboxing experience

If you’re producing large volumes, automated sealers with temperature-controlled wraps offer consistency and speed.

6. Quality Control: Final Inspection and Storage

Before distribution, conduct a quality check to:

Inspect for leaks or oil stains

Confirm push-up mechanism works smoothly

Check print alignment and label application

📦 Storage tips:

Store tubes in a dry, cool area

Avoid direct sunlight and excess humidity

Use inner poly bags for bulk shipments to protect against dust

Get Your Process Right from the Start

Mastering how to fill paper lip balm tubes and following proven lip balm tube sealing tips ensures your eco-conscious packaging meets functional standards. Whether you’re launching your first small-batch balm or scaling a national line, success starts with understanding your tube, controlling your environment, and refining your process.

Need help with testing or sourcing food-safe, sustainable lip balm tubes? Our team at All Paper Tube Co. is ready to guide you, contact us now!