As modern consumer attitudes shift and environmental awareness increases, the food packaging industry is continually innovating. Paper tube packaging, as an emerging form of packaging, is gradually gaining a significant foothold in the food industry. This article will explore the current state and trends of food-grade paper tube packaging, its popularity reasons, application areas, and how to customize food-grade sealed paper tube packaging with a specific process.

Table of Contents

1.Current State and Trends of Food Paper Tube Packaging

2. Why Food-Grade Paper Tube Packaging is Popular?

2.1 Environmental Protection and Sustainability

2.2 High Customization and Brand Identity

2.3 Superior Protective Performance

2.4 Multifunctionality and Convenience

2.5 Cost-Effectiveness

2.6 Wide Market Applications

3. Basic Requirements for Food-Grade Paper Tube Packaging

3.1 Food-Grade Materials

3.2 Sealing and Freshness Preservation

3.3 Structural Integrity

3.4 Shelf Life Extension

4. Food-Grade Paper Tube Packaging Options

4.1 Composite Paper Canister: The Preferred Solution for Food Packaging

4.1.1 Material Composition

4.1.2 Advantages

4.1.3 Application Areas

4.2 Paper-base paper tube: An Eco-Friendly and Versatile Food Packaging Solution

4.2.1 Material Composition

4.2.2 Advantages

4.2.3 Disadvantages

4.2.4 Application Scenarios

4.2.5 Optimization Solutions

4.2.6 Application Areas

5. How to Customize the Right Packaging Solution for Your Food Products?

5.1 Understand the Characteristics and Needs of the Food

5.1.1 Food Type

5.1.2 Shelf Life Requirements:

5.1.3 Market Positioning and Brand Image

5.2 Choose the Right Packaging Materials and Types

5.2.1 Paper Canister

5.2.2 Paper Based Paper Tube

5.3 Customization Process

5.4 Consider Environmental and Sustainability Factors

5.5 Get Professional Advice

Conclusion

1. Current State of Food-Grade Paper Tube Packaging

Current State

At present, the application scope of food paper tube packaging is expanding. Whether high-end food brands or small and medium-sized enterprises, many are adopting this new packaging method. Its advantages lie in being both aesthetically pleasing and practical, meeting various consumer needs.

2. Why Food-Grade Paper Tube Packaging is Popular?

Food-grade paper tube packaging is increasingly becoming a popular choice in the food industry due to its significant advantages in functionality, sustainability, and aesthetics. Here are the major benifits of food-grade paper tube packaging in the food industry:

2.1 Environmental Protection and Sustainability

As consumers become more environmentally conscious, companies are placing greater emphasis on the sustainability of packaging materials. Food-grade cylinder packaging, typically made from recyclable and biodegradable paper materials, aligns with the current trend of green sustainability.

- Renewable Materials: More brands are opting for paper from sustainably managed forests, reducing their environmental impact.

- Reducing Plastic Use: By adopting all-paper or composite paper cans, reliance on plastic is minimized, further promoting environmental protection.

2.2 High Customization and Brand Identity

Food-grade cylinder packaging offers a high degree of customization options, catering to different brands’ unique packaging design needs.

- Innovative Designs: A variety of shapes and sizes, combined with high-quality printing techniques, allow brands to create unique and attractive packaging.

- Brand Storytelling: Packaging design can convey the brand’s story and philosophy, strengthening the emotional connection with consumers.

2.3 Superior Protective Performance

Food paper tube packaging excels in protecting food, making it especially suitable for foods that require moisture and oxidation resistance.

- Sealing Performance: By adding moisture-proof liners and sealing lids, food remains fresh during transportation and storage.

- Structural Stability: The sturdy cylindrical structure protects food from external pressure and impact during transportation.

2.4 Multifunctionality and Convenience

Food-grade paper tube packaging not only protects food but also provides a convenient user experience for consumers.

- Easy-to-Open Design: Easy-peel and pull-tab lids make it easy for consumers to open the packaging and use the product.

- Reusable Design: Some cylindrical packaging is designed to be reusable, offering additional practical value to consumers.

2.5 Cost-Effectiveness

Paper tube packaging is relatively cost-effective compared to other packaging materials like glass or metal. It offers a balance between functionality and cost, making it a popular choice for many food brands.

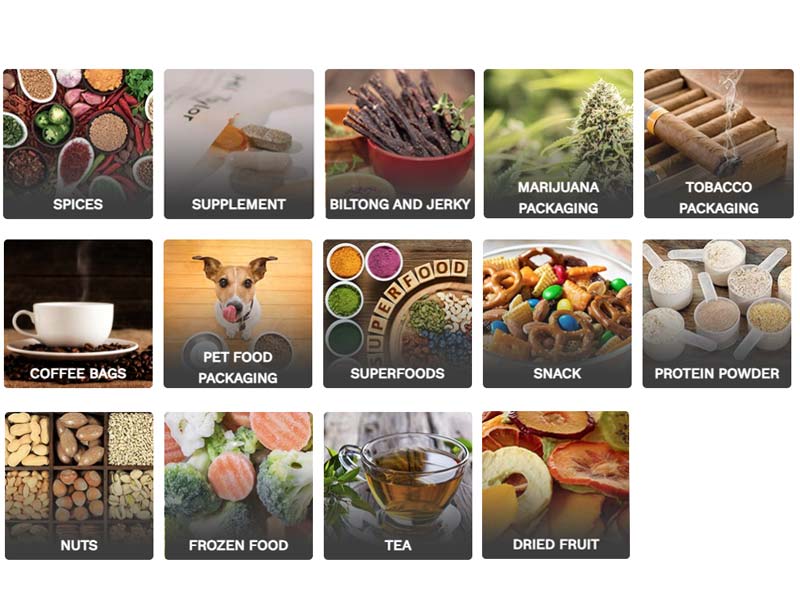

2.6 Wide Market Applications

Food paper tube packaging is suitable for various types of food, with a wide range of market applications.

- Dry Food: Such as coffee beans, tea, grains, and nuts, using its excellent moisture resistance to maintain the original flavor.

- Snacks and Confectionery: Such as biscuits, candies, and chips, attract consumers with exquisite packaging design.

- Powdered Food: Such as nutritional powder, protein powder, and spices, providing convenient storage and use solutions.

3. Basic Requirements for Food-Grade Paper Tube Packaging

When it comes to food-grade paper tube packaging, several crucial requirements must be met to ensure the safety, quality, and appeal of the packaged food products. Here are the key requirements we think are the most important:

3.1 Food-Grade Materials

- Safety Standards: The materials used in the packaging must comply with food safety standards and regulations, such as those set by the FDA, EFSA, or other relevant authorities. This ensures that the materials do not contain harmful chemicals or contaminants that could migrate into the food.

- Non-Toxic: All inks, adhesives, and coatings used in the packaging should be non-toxic and safe for food contact.

3.2 Sealing and Freshness Preservation

- Airtight Sealing: The packaging must be capable of creating an airtight seal to prevent exposure to air, which can lead to oxidation and spoilage of the food.

- Moisture Barrier: Effective moisture resistance is crucial to prevent food from becoming soggy, moldy, or losing its texture.

- Light Barrier: For light-sensitive foods, the packaging should provide a barrier against light to preserve color, flavor, and nutritional value.

3.3 Structural Integrity

- Durability: The packaging should be sturdy enough to protect the contents from physical damage during transportation, handling, and storage.

- Impact Resistance: It should withstand impacts and prevent crushing or breaking of delicate food items like cookies or chips.

3.4 Shelf Life Extension

- Preservation Properties: The packaging should have properties that help extend the shelf life of the food, such as oxygen barriers, desiccants, or modified atmosphere packaging.

- Barrier Layers: Incorporating barrier layers like aluminum foil, PE coatings, or other materials can help protect the food from external factors.

There are more requirements we need to consider about, while we think those are must important,especially the sealing airtightness issue, any food pacakging must meet it.

4. Food-Grade Paper Tube Packaging Options

In the food packaging field, composite canister and paper based paper tube are essential choices, each with its unique advantages and application scenarios. Here is a detailed explanation of these two packaging solutions:

4.1 Composite Paper Canister: The Preferred Solution for Food Packaging

If you were looking for a round paper tube packaging for your food products, composite paper canister is the top recommendation from us.

It features in airtight tube packaging because of its enclosure is sealed by machine, making it perfect food packaging providing long shelf life.Besides it gets more benifits, let us introduce it in deep for you below, and you can see more portfolios from here.

4.1.1 Material Composition

- Kraft Paper Tube: The outer layer is made of kraft paper, providing a sturdy structure and natural appearance.

- Food-Grade Aluminum Film Liner: The inner layer is covered with food-grade aluminum film, offering excellent moisture and oxygen barrier properties.

- Top Seals: Various custom options, including aluminum foil easy-peel lids, easy-peel films, pull-tab lids, and composite lids.

- Tinplate Bottom Lid: The bottom uses a tinplate lid, sealed by machine for robustness and sealing performance.

4.1.2 Advantages

Excellent Sealing:

- Moisture Barrier: The food-grade aluminum film liner effectively blocks moisture, keeping food dry and preventing mold.

- Oxygen Barrier: The aluminum film prevents oxygen from entering, preventing food oxidation and extending shelf life.

Variety of Top Sealing Options:

- Easy-Peel Lids: Aluminum foil easy-peel lids are convenient for frequent opening and consumption.

- Easy-Peel Films: Aluminum foil easy-peel films provide sealing and are easy to peel, commonly used for powdered foods.

- Pull-Tab Lids: Similar to can lids, suitable for high-end foods and imported snacks.

- Composite Lids: Dual-layer protection, suitable for foods requiring high sealing and moisture resistance.

Robust Bottom Structure:

- Tinplate Bottom Lid: Machine-sealed for a sturdy bottom structure, ensuring food safety during transportation and storage.

4.1.3 Application Areas

- Coffee and Tea: Retains aroma and freshness, prevents moisture.

- Biscuits and Nuts: Prevents crushing and retains crispness.

- Nutritional Powders and Seasonings: Prevents clumping and retains original flavor.

- Natural Foods: Eco-friendly packaging, aligning with green health concepts.

- High-End Snacks: Enhances product grade and brand image.

4.2 Paper-base paper tube: An Eco-Friendly and Versatile Food Packaging Solution

This is a packaging solution that many customers love but we don’t highly recommend. Since paper lacks flexibility and elasticity, and because the top and bottom lids are glued, there can be small gaps, making it not a completely sealed cylindrical packaging. However, we have always wondered why it remains popular among many customers. Besides adding an aluminum foil liner for moisture resistance, there aren’t many sealing options available during customization. We believe it is popular due to the following advantages:

4.2.1 Material Composition

- Primarily Made of Paper: Both the outer and inner layers are made of high-quality food-grade paper.

4.2.2 Advantages

Eco-Friendly and Recyclable:

- Biodegradable: Made of paper, biodegradable, and environmentally friendly, suitable for brands focusing on sustainability.

- Recyclable: Easy to recycle, reducing environmental impact.

Diverse Design Options:

- Flexibility: Can be designed and printed according to brand needs, enhancing product market appeal.

- Lightweight: Lightweight, easy to transport and store, reducing logistics costs.

4.2.3 Disadvantages

- Weaker Sealing: Due to the nature of paper, paper-made paper tubes lack excellent sealing properties and are usually used as secondary packaging.

4.2.4 Application Scenarios

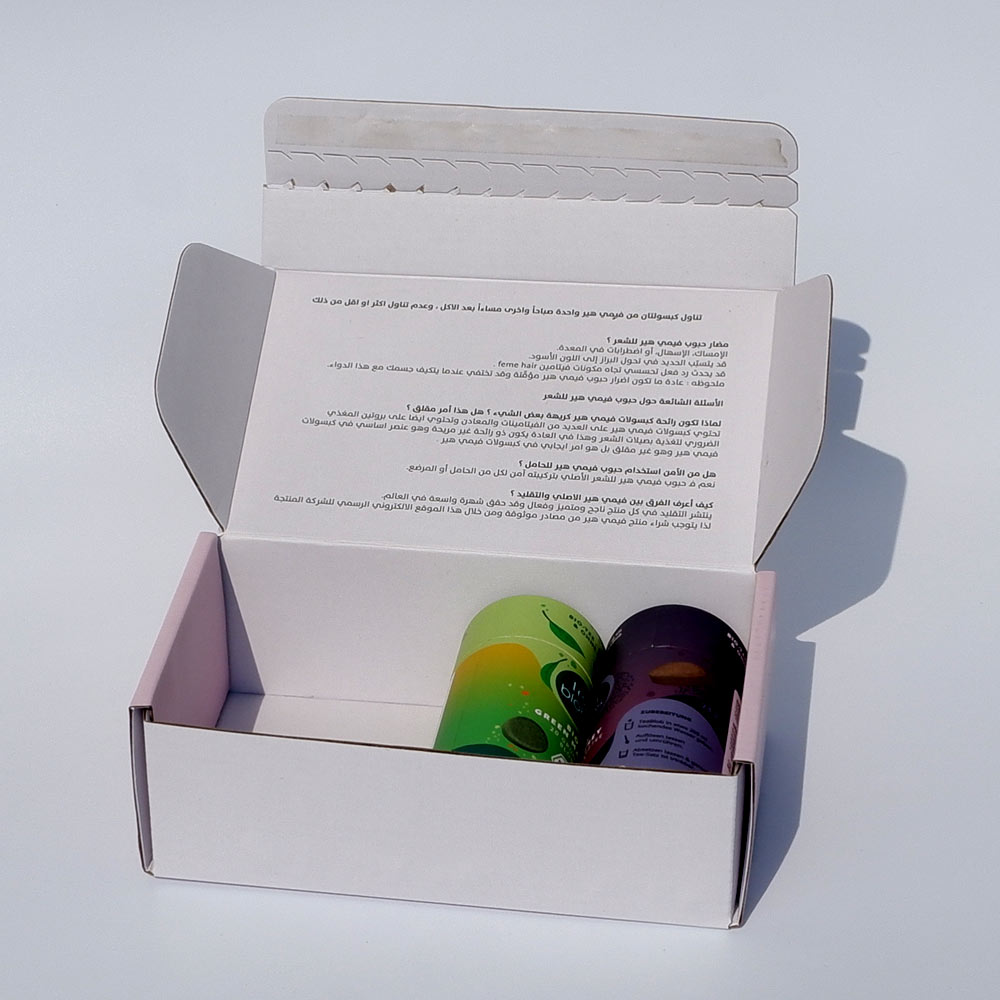

- Secondary Packaging: Commonly used as outer packaging for food, protecting the inner packaging and enhancing aesthetics.

- Direct Usage Improvements: If needed for direct food packaging, moisture and oxygen barrier liners and sealed top and bottom lids can be added to improve sealing performance.

4.2.5 Optimization Solutions

Despite the numerous advantages mentioned above, we still recommend sealed composite cans as our preferred solution for food packaging. If you truly prefer all-paper cans, we can also customize and optimize them to meet the shelf life requirements of food packaging. Below are some optimization solutions we have customized for our clients. Although some of these may not achieve complete sealing, they are tailored to client needs and are provided here for your reference.

Add Liner: Add a moisture and oxygen barrier material (such as PE coating or aluminum foil) to the inner wall of paper tube can to enhance its moisture and oxygen barrier properties.

Sealed Lids: Add sealed lids to the top and bottom, using PE lids or other plastic materials to enhance the can’s sealing, preventing air and moisture from entering.

4.2.6 Application Areas

- Dry Foods: Such as grains, flour, candies, etc.

- Eco-Friendly Products: Suitable for products emphasizing environmental sustainability, such as organic and natural products.

Composite paper canister and paper-made paper tube packaging each have unique advantages and application scenarios. Composite paper canisters are the preferred solution for food packaging due to their excellent sealing performance and diverse design options. paper-made paper tube, with their eco-friendliness and flexibility, are ideal for brands focusing on sustainability. Depending on the specific type of food and packaging needs, the most suitable packaging solution can be chosen to ensure the safety, quality, and market competitiveness of the food.

5. How to Customize the Right Packaging Solution for Your Food Products?

Customizing the right packaging solution for your food products involves considering multiple factors, including the characteristics of the food, shelf life, market positioning, and environmental requirements. Here are the detailed steps and recommendations for customizing food packaging solutions:

5.1 Understand the Characteristics and Needs of the Food

5.1.1 Food Type

- Dry Foods: Such as grains, flour, biscuits, nuts, etc., usually require moisture-proof and anti-oxidation packaging.

- Powdered Foods: Such as coffee powder, spices, nutritional powder, etc., require easy-to-open packaging that prevents clumping.

- Moist Foods: Such as sauces, honey, etc., require highly sealed and leak-proof packaging.

- High-End Foods: Such as premium snacks and imported foods, require high-end and unique packaging designs.

5.1.2 Shelf Life Requirements:

- Determine the shelf life of the food to select suitable barrier materials that ensure freshness and safety throughout the shelf life.

5.1.3 Market Positioning and Brand Image

- Consider the brand’s market positioning and image, and choose packaging designs that enhance brand value.

5.2 Choose the Right Packaging Materials and Types

5.2.1 Paper Canister

- Applicable Range: Suitable for various foods that require high sealing performance, such as coffee, tea, biscuits, nuts, nutritional powder, etc.

- Material Composition: Outer kraft paper, food-grade aluminum film lining, aluminum foil easy-peel lid, pull-tab lid, tinplate bottom lid, etc.

- Advantages: Excellent sealing performance, moisture-proof and anti-oxidation, diverse design options, sturdy structure.

5.2.2 Paper Based Paper Tube

- Applicable Range: Suitable for dry foods and eco-friendly products, such as grains, flour, candies, organic foods, etc.

- Material Composition: Primarily made of food-grade paper, can add moisture and oxygen barrier liners and sealed top and bottom lids to enhance sealing performance.

- Advantages: Eco-friendly, recyclable, biodegradable, flexible design, lightweight.

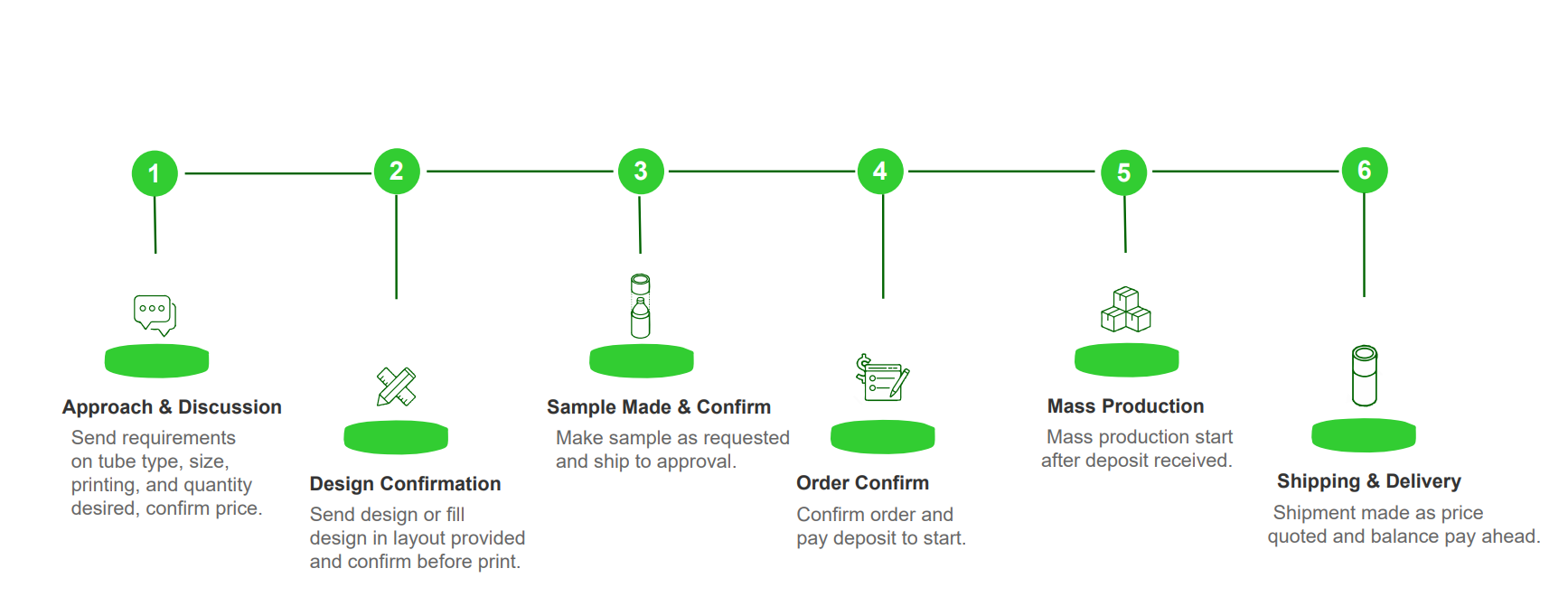

5.3 Customization Process

The custom food paper tube packaging process is a collaborative and detailed journey that involves:

- Information Communication and Confirmation: Gathering and confirming all necessary details, tube type, size, printing & quantity.

- Design Draft Confirmation: Creating and refining design drafts until final approval.

- Sample Confirmation: Producing and approving a prototype sample sent.

- Order Confirmation: Order will be started with a 50% deposit paid.

- Mass Production: Manufacturing the packaging in bulk, normally take like 18-20days.

- Shipping and Delivery: Ensuring the final product reaches you safely and on time.

By following these steps, you’ll ensure your packaging not only looks fantastic but also aligns perfectly with your brand’s vision and needs. And our packaging specialists will guide you on each steps too.

5.4 Consider Environmental and Sustainability Factors

Eco-Friendly Materials:

- Choose recyclable, biodegradable packaging materials to reduce environmental impact and meet modern eco-friendly trends.

Sustainable Development:

- Consider the sustainability of the packaging, choosing materials and processes that reduce carbon footprint and resource consumption.

Brand Promotion:

- Use eco-friendly packaging to enhance brand image and market competitiveness, attracting environmentally conscious consumers.

5.5 Get Professional Advice

Consult Our Professional Packaging Specialist:

- Packaging customization is a meticulous task that leaves no room for error, and it must be approached with great care and attention. Our packaging consultants not only possess professional packaging knowledge but are also patient and detail-oriented. We are committed to providing you with high-quality service.

Continuous Optimization:

- Continuously optimize and improve the packaging solution based on market feedback and consumer needs, enhancing product competitiveness.

By following these steps, you can customize a packaging solution that fits your food products, ensuring their safety, quality, and market appeal. Choosing the right packaging materials and design can also enhance brand image and achieve sustainability goals. If you have further needs or questions, feel free to contact us for more customized advice.

Conclusion

After reading this guide on customizing food-grade cylinder packaging, we believe you now have a deeper understanding of the application of cylinder packaging in the food industry. If you want to customize food-grade cylinder packaging or have any other questions, please contact us, and we will provide you with detailed answers.