Eco-friendly lip balm packaging is a fantastic sustainable choice, but it must be compatible with your product’s formula. Recently, a few customers noticed that after filling their compostable paper lip balm tubes, the thin plastic-based protective film lining the inner tube started to crack and peel. The good news: the inner oil-resistant wax paper lining of eco-friendly lip balm packaging remained intact, and the structural integrity of the paper tube was fine.

The likely culprit was the lip balm formula itself—specifically, some strong volatile ingredients in the balm that reacted with the tube’s outer protective coating. This situation highlights an important point for any brand using eco-friendly lip balm packaging: you must ensure your recipe plays nice with the packaging materials.

Why Can Eco-Friendly Tubes Crack or Peel?

Even the best eco-friendly lip balm packaging can have vulnerabilities if exposed to aggressive ingredients. In our paper tubes, the main body is sturdy paperboard with a wax paper interior lining (designed to resist oils), plus a very thin plastic film on certain surfaces for added protection and smooth operation. If your lip balm contains high levels of volatile oils, alcohol, or potent essential oils, these substances can attack and weaken the thin film of your eco-friendly lip balm packaging, leading to cracking and peeling over time.

Many essential oils are natural solvents that can break down certain plastics, for example, the compound d-limonene in citrus oils can easily dissolve polystyrene. If a thin plastic film is exposed to similarly potent oils, it’s no surprise it might crack. Likewise, ethanol (alcohol) in a formula can act as a solvent that affects adhesives or coatings. In contrast, more durable plastics like HDPE (#2 plastic) have stronger bonds that are not broken by essential oils. This is why conventional lip balm tubes (typically polypropylene or HDPE) usually handle essential oils without issue. But with compostable paper tubes, there’s less plastic involved, so any remaining plastic layer deserves extra care and testing.

Ingredient & Packaging Compatibility 101

Cosmetic chemists know that packaging and formula must work together. When developing a new balm (especially all-natural ones with lots of essential oils or flavor oils), it’s wise to do a compatibility test: fill one tube and observe it for a few weeks. Check if the balm discolors the paper, if any oil is seeping through, or if the liner film is degrading. High concentrations of components like peppermint, citrus, eucalyptus, or cinnamon oil, for instance, can be a red flag. Not only can such ingredients irritate skin in excess, they are also more likely to attack sensitive materials. Always use essential oils within recommended safe percentages for lip products (usually a very small fraction of the formula) and consider using oil-soluble flavor compounds that are less aggressive on packaging.

Remember that even “natural” ingredients can be surprisingly powerful. The interaction goes both ways: an incompatible package might alter your product’s scent or consistency, and a strong formula can compromise the package. Stability testing in real-world conditions (room temperature, heat, etc.) will reveal any issues before you commit to a full production run. If the plastic film in a paper tube is going to crack from your recipe, it’s better to find out with one test unit than after shipping a thousand units to customers!

Best Practices to Prevent Packaging Damage

Fortunately, there are several steps you can take to enjoy eco-friendly lip balm packaging without hiccups. Here are some tips to protect both your eco-friendly lip balm packaging packaging and your product:

-

Adjust Your Filling Temperature: When pouring your hot lip balm mixture into eco-friendly lip balm packaging, avoid excessive heat. Extremely high fill temperatures can not only risk burning the paper, but also cause the plastic liner to warp or weaken. Let your mixture cool slightly (while still liquid) before filling. A good practice is to pour at the lowest temperature that still allows a smooth fill.

-

Don’t Cap Immediately: After filling, leave the tubes uncapped until the balm solidifies and cools to room temperature. This allows any initial vapors from volatile oils or alcohol to dissipate. Capping too soon traps those vapors, which can concentrate and condense on the tube’s interior (increasing the chance of material breakdown or even making the balm “sweat”). Giving the balms some breathing time helps protect that inner coating.

-

Use Recommended Ingredient Levels: Formulate with packaging in mind. If you love a certain essential oil, use it sparingly and within advised limits. For example, using around 1% peppermint oil for flavor might be safe, but 5% would be excessive and potentially harsh on both lips and the tube. The same goes for any ingredient known to be a strong solvent. If you need a robust scent, consider using stabilized flavor oils or lower-volatility extracts rather than a heavy dose of pure essential oils.

-

Test a Sample Batch: Before scaling up, always test your balm in a few tubes and observe them over time. You can even accelerate the test by storing one filled tube at a slightly elevated temperature (say 30–35 °C / 86–95 °F) for a week to simulate a hot climate. This can reveal any creeping oil, softening, or cracking of liners early on. If the packaging holds up under these conditions, that’s a good sign. (As a simple at-home experiment, you can also apply a drop of your most potent essential oil to a spare piece of the tube material to ensure it doesn’t cause any change to the coating.

-

Store and Transport Wisely: Finished lip balm products should be kept in a cool, dry place. Heat can exacerbate the volatility of oils and the softness of waxes, which might amplify interactions with the packaging. While normal use conditions are fine, avoid leaving inventory in very hot cars or in direct sun for long periods, especially before they reach customers.

By following these tips, brands can maximize the life and performance of their eco-friendly lip balm packaging while still delivering sustainable beauty solutions to eco-conscious consumers.

Considering Alternative Packaging for Tough Formulas

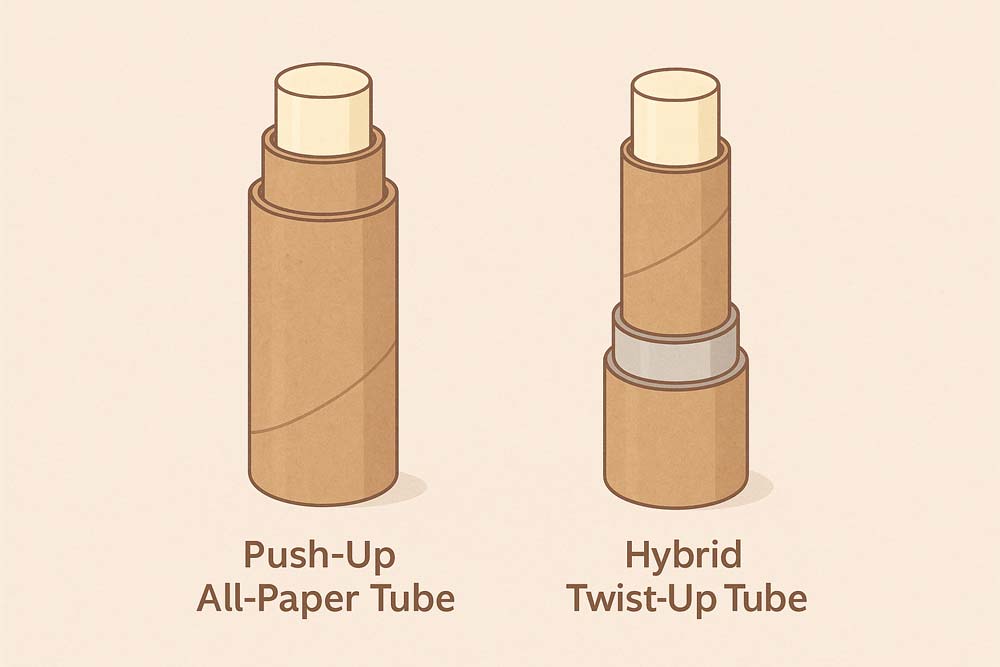

What if your signature balm simply has to have a high dose of a tricky ingredient? If you find that no amount of tweaking can prevent the protective film from reacting, it might be time to consider alternative packaging that still aligns with your sustainability goals. One option is a hybrid paper-plastic tube, where the outer shell is paperboard but there’s a minimal plastic inner mechanism (often a twist-up design). The plastic inner component (usually made of polypropylene or HDPE) can handle aggressive oils much better, while the outer paper still provides an eco-friendly look and reduces overall plastic usage. This way, you get the best of both worlds: a mostly sustainable lip balm packaging solution with the functionality and chemical resistance of a traditional tube.

Another alternative is to use small glass or aluminum containers (like screw-top tins) for formulas that are incompatible with paper lip balm tubes of any kind. Many artisanal brands sell balms in flat metal tins or glass pots. These materials are impervious to essential oils and alcohol. Of course, the user experience is different (applying with a finger instead of a twist-up stick), and tins aren’t tubes – but they can be a classy, eco-conscious option for special-edition balms that have challenging ingredients.

Formulation and Packaging Go Hand-in-Hand

In summary, encountering a peeling liner or cracked coating in your eco-friendly lip balm packaging doesn’t mean you need to abandon sustainable packaging—it means it’s time to fine-tune your approach. By understanding the interaction between your balm’s ingredients and the packaging materials, you can adjust your recipe or processes to prevent issues. Simple steps like mindful formulation, proper filling methods, and thorough testing can save you a lot of headaches down the road.

At All Paper Tube Co., we have extensive experience in crafting custom paper lip balm tubes that not only look great but also stand up to real-world use. We’re here to help you troubleshoot and find the perfect packaging for your unique formula—whether that means tweaking a coating, adding an extra barrier, or exploring a hybrid design. With a little collaboration between your product development team and our packaging experts, you can confidently offer lip balms in sustainable, custom packaging that performs as beautifully as it looks. Your creativity paired with our know-how ensures that your lip balm and its package are a perfect match!