Custom paper tube packaging can make your products stand out – or fall flat – depending on the choices you make. In fact, 72% of consumers say packaging design influences their purchase decisions. For small business owners and brand managers, avoiding common packaging errors is key to saving costs and building a strong brand image. This guide will show you how to avoid packaging errors when designing and producing paper tubes. We’ll cover mistakes (and fixes!) in design, material selection, sizing, printing, and production.

1. Design: Keep Branding Consistent and Clear

Design is one of the most common areas where custom paper tube packaging mistakes happen. Poor design choices like unclear messaging or inconsistent branding can confuse or frustrate customers.

Common Mistakes: Using inconsistent branding or cluttered graphics on your tube can confuse customers. For example, mismatched colors or logos across products make your brand seem disorganized. Some companies even print the wrong panel or place important text where it’s hard to see – rookie errors that hurt credibility.

Actionable Tips:

Maintain Brand Consistency: Stick to your brand’s approved colors, fonts, and logo placement on all packaging. Establish clear brand guidelines and templates to ensure every design aligns with your identity. Consistent visuals help shoppers instantly recognize your product on a shelf.

Simplify and Clarify: Less is more. Avoid overloading the tube with too much text or imagery. Make sure the product name and key info are easy to read at a glance (no super tiny fonts or confusing graphics). Clear design improves customer understanding and encourages trust.

Proof and Test: Always review design proofs or mock-ups. Check that critical details (like instructions or flavor variants) are visible and not accidentally printed on the bottom or hidden by the cap. Maybe even create a sample tube to see the design in 3D and ensure nothing important falls on a seam or crease.

2. Material Selection: Choose Durable, Eco-Friendly Materials

Choosing the wrong materials is another source of custom paper tube packaging mistakes. Materials that are too thin or not suitable for the product can damage the product or hurt your brand’s eco reputation.

Common Mistakes: Selecting the wrong tube material can spell disaster. Thin or low-quality cardboard might dent or crush, failing to protect your product. Ignoring sustainability is another pitfall – today’s consumers care about eco-friendly packaging, and 67% say materials impact their buying decisions. If your paper tube isn’t sturdy or doesn’t align with customer values, you risk complaints or lost sales.

Actionable Tips:

Match Material to Product Needs: Choose a tube strength and lining appropriate for your product. For example, a food item might need a foil-lined or moisture-resistant interior for freshness, while a cosmetic lip balm could use an oil-resistant lining in a push-up tube. Don’t use cheap, flimsy tubes for heavy or fragile goods – invest in thick-walled tubes that protect against crushing and moisture.

Don’t Overlook Child-Resistance (If Needed): If your product requires safety packaging (e.g. certain supplements or cannabis products), consider a child-resistant paper tube design. These have special caps or locking mechanisms. Skipping this when it’s legally required or expected can be a costly mistake. Always check compliance for your industry.

Opt for Eco-Friendly Options: Demonstrate your brand’s commitment to sustainability by using recyclable, biodegradable paper tubes and soy-based inks when possible. This appeals to eco-conscious consumers. (For instance, about 71% of Americans are more likely to buy brands with paper or cardboard packaging over plastic.) If you must use some plastic (for food safety or durability), use it sparingly and be transparent about it.

3. Sizing: Get the Dimensions Right

A major category of custom paper tube packaging mistakes is related to product sizing. Tubes that are too big waste space and shipping costs, while those too small damage the product.

Common Mistakes: Size matters! A frequent error is using one-size-fits-all tubes that are too large or too small for your product. Oversized tubes lead to wasted space, higher shipping costs, and the need for extra filler. Undersized tubes can damage the product or simply not fit it at all. Small businesses sometimes try to cut corners by picking one generic tube size – but this “shortcut” often becomes an expensive mistake.

Actionable Tips:

Measure and Prototype: Carefully measure your product (height, diameter, etc.) and request a sample tube or prototype in that size before bulk ordering. Testing with a real sample ensures your product fits snugly and looks good. Adjust the dimensions if needed; many suppliers can customize tube diameter/height to the millimeter.

Avoid Empty Space or Overstuffing: There should be minimal empty space inside the tube, but also don’t cram it full. If a slightly larger tube is necessary, use inserts or padding (e.g. recyclable crinkle paper or foam) to secure the item and prevent it from rattling. This protects your product and maintains a premium feel when opened.

Consider Shipping and Storage: Remember that larger tubes cost more to ship and store. Choose the smallest size that comfortably fits your product and any inner packaging. A right-sized tube saves on postage and reduces the risk of damage (since the product won’t jostle around). For example, using a huge tube for a small item could increase your fulfillment costs unnecessarily.

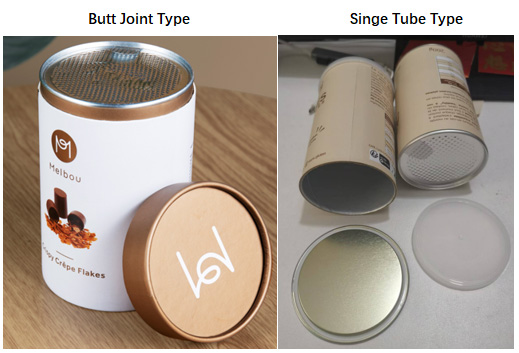

Check Cap Fit: If your tube has a separate cap/lid, test how it fits. Some caps can be too tight or too loose due to small variations in paper tubes. Communicate with your supplier about your preference (easy-open vs snug fit) and test multiple units. It’s normal for paper tubes to have slight differences, so ensure the average fit meets your expectations.

4. Printing: Ensure High-Quality Prints and Colors

Low-res graphics, poor color matching, or misaligned prints are frequent custom paper tube packaging mistakes that can harm your brand’s professional appearance.

Common Mistakes: A beautiful design can be ruined by poor printing. Common printing mistakes include low-resolution graphics that appear blurry, colors that don’t match your brand (e.g., a “red” prints as dull maroon), or misaligned prints around the tube (so designs don’t line up at the seam). Small businesses might also pick the wrong print method – for instance, choosing a method not suited for their quantity or artwork, leading to faded colors or higher costs.

Actionable Tips:

Use High-Resolution Artwork: Always provide artwork at 300 DPI or higher for clarity. This prevents pixelation on the finished tube. If you use photographs or intricate patterns on the tube, check that they remain sharp in print proofs.

Select the Right Printing Process: Understand your options – digital printing is great for short runs or prototypes, while offset printing (using CMYK or Pantone inks) yields the most exact color match for larger runs. For bold brand colors, Pantone spot printing can keep colors consistent and vibrant. Discuss with your printer which method fits your design and budget to avoid unwanted surprises (like color shifts or high per-unit costs).

Mind the Color Mode: Design in CMYK color mode for print or use Pantone colors if you need exact matches. Designing in RGB (for screens) or forgetting to convert colors could result in dull or inaccurate hues on the physical tube. Always request a color proof or sample to verify the output, especially for critical brand colors.

Check Alignment and Bleeds: Cylindrical packaging can be tricky – make sure graphics that wrap around line up correctly. Include bleed area in your design file so that prints aren’t misaligned or leaving white seams. For example, if you have a pattern or text that nearly wraps the whole tube, ensure it meets perfectly at the join. Review printer proofs to catch any alignment issues before mass production (like text accidentally creeping onto the tube’s edge or cap area).

5. Production & Quality Control: Plan, Test, and Communicate

Failing to test samples or rushing into production are some of the most expensive custom paper tube packaging mistakes. Solid quality control can save you from major setbacks.

Common Mistakes: Rushing into production without proper testing or communication can lead to costly errors. Examples include not catching a typo or wrong color until after thousands of tubes are made, or realizing the tube closure isn’t secure only when customers complain. Some businesses also underestimate lead times or minimum order quantities, ending up in a bind with packaging delays. Skipping quality checks – or “cutting corners” to save money – often results in damaged goods and unhappy customers.

Actionable Tips:

Order Samples and Do Test Runs: Before full production, always request a small batch or sample tube. Use it to test everything – fit, print quality, durability (maybe perform a drop test or leave it in a humid room to see how it holds up). It’s much easier to tweak issues in the sample stage than after you’ve ordered 5,000 units.

Coordinate with a Reliable Manufacturer: Work closely with an experienced packaging supplier who can guide you. Provide them with all necessary details (product dimensions, any special requirements like food-grade liners, etc.) and ask questions. A good manufacturer will help catch potential problems early and suggest improvements. Don’t be afraid to rely on their expertise.

Plan Ahead for Timelines: Custom paper tubes can have minimum order quantities (often 1000 or more) and longer production times than off-the-shelf packaging. Avoid last-minute orders – give yourself padding in your timeline for design revisions, production, and shipping. Starting early prevents a panic if something needs a fix.

Inspect the Finished Product: When your bulk order arrives, inspect a sample of tubes before using them. Check print accuracy, structural integrity, and cap fit across multiple units. This quality control step ensures any defects are caught immediately. It’s better to hold back a flawed package than to ship products in packaging that fails (e.g., tubes popping open or graphics misprinted). Remember, packaging mistakes can lead to returns or damage that cost you money and reputation, so a final inspection is worth it.

Continuous Improvement: Gather feedback once your packaging is in use. If customers mention difficulty opening the tube or if you observe an unusual number of damaged products during shipping, use that insight for your next production run. Packaging is an iterative process – learn and adjust to keep improving.

Conclusion & Key Takeaway

Custom paper tube packaging is a fantastic way to showcase your brand’s creativity and commitment to quality – as long as you avoid the common pitfalls. By focusing on clear design, sturdy and sustainable materials, proper sizing, quality printing, and diligent production practices, you set your product up for success. Small businesses that get packaging right can boost customer satisfaction and even attract new buyers (81% of consumers tried something new because the packaging caught their eye). In short, pay attention to the details now to avoid expensive packaging errors later. With these tips in hand, you’re well on your way to creating paper tube packaging that delights customers and strengthens your brand’s image. Happy packaging!

About All Paper Tube Co.

At All Paper Tube Co., we specialize in custom paper tube packaging that’s not only eco-friendly but also thoughtfully engineered to avoid the common mistakes brands face. Whether you’re a small business launching your first product or an established brand refining your packaging, we offer design, material, and printing expertise that brings your vision to life—beautifully and reliably.