Hey there, beauty enthusiasts! Let’s dive into the world of paper tube lip balm push-up packaging, an innovative and eco-friendly choice that’s taking the market by storm. Here’s everything you need to know about this awesome packaging, from its stylish looks to how it works and how it recycles!

Keep reading:

Chapter 1: Curious About Fun and Eco-Friendly Paper Tube Lip Balm Push-Up Packaging?

Let’s explore further.

1.1 What’s lip balm push-up paper tube?

Stylish Looks

Sleek and Cylindrical Design: our paper tube lip balm push-up packaging boasts a sleek, cylindrical shape that’s perfect for holding and carrying around. It’s simple, chic, and fits any occasion.

Eco-Friendly Paper Material: The outer layer is made from high-quality paper materials, customizable to suit your brand’s needs. Choose from recycled paper, kraft paper, or other sustainable options, all with a planet-friendly twist.

Custom Printing and Decoration: Get creative with various printing and decoration techniques like foil stamping, embossing, and UV printing. Show off your brand’s logo, product info, and eye-catching designs to make your packaging truly stand out.

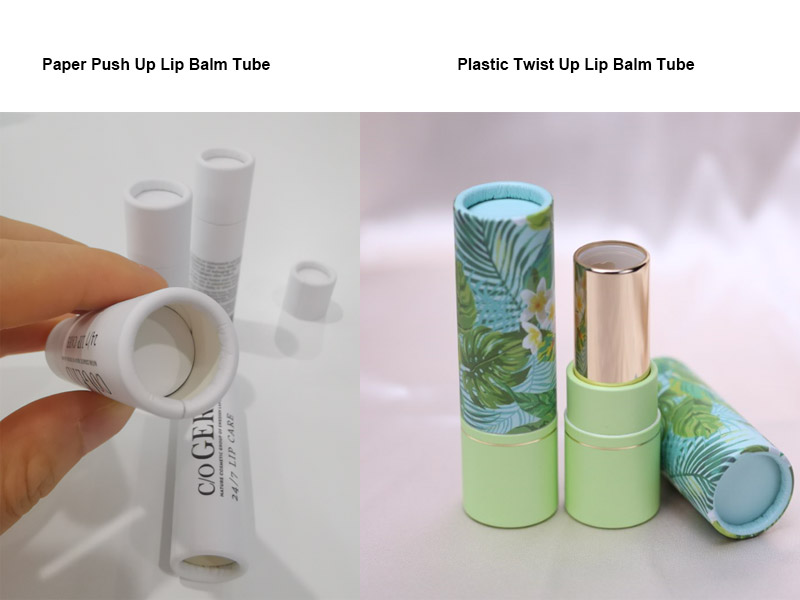

Convenient Closure: our packaging features easy-to-use closure mechanisms to keep your lip balm safe and secure when not in use. Popular options include bottom paper disc push up, bottom plastic twist up, ensuring both safety and convenience for your customers.

1.2 What are the benefits of using paper lip balm tube packaging?

Eco-Friendly: Made with sustainable paper materials, our packaging aligns with modern consumers’ eco-conscious values. Paper is easy to recycle and decomposes naturally, reducing environmental impact.

Lightweight: Paper tube packaging is lightweight and portable, making it perfect for on-the-go use or travel. This added convenience makes our packaging a practical choice for busy lifestyles.

Aesthetic Appeal: With customizable designs, our paper tube lip balm push-up packaging can reflect your brand’s unique style, from minimalist elegance to luxurious opulence. Your packaging will not only protect your product but also enhance its visual appeal.

Safety First: Our non-toxic, safe-to-use paper materials meet all cosmetic packaging safety standards. This ensures that your lip balm remains uncontaminated and intact, ready for smooth application every time.

1.3 How It Works

Push-Up Mechanism: The heart of our packaging is its nifty push-up mechanism. Inside, a movable base lets users push the lip balm up as needed. Simply press the bottom to raise the balm– easy peasy!

User-Friendly: Operating the push-up mechanism is a breeze. Just a gentle push on the bottom to adjust the balm’s length, making it super intuitive and hassle-free.

Sealed for Freshness: The push-up design ensures that the lip balm is fully sealed when not in use, keeping out dust and air to maintain its quality. The secure cap adds an extra layer of protection for a fresh and safe product.

With all these fantastic features, it’s clear that paper tube lip balm push-up packaging is not just trendy but also practical, safe, and environmentally responsible. It’s time to elevate your product’s market appeal while showing off your brand’s commitment to sustainability and innovation. Ready to make the switch? Let’s get started!

Chapter 2: How to Customize Paper Tube Lip Balm Packaging to Highlight Your Brand

Creating standout paper lip balm packaging is a fantastic way to reflect your brand’s unique identity and commitment to sustainability. Here’s how you can do it:

2.1 Structural Design Choices:

Push-Up Tubes: These are popular and eco-friendly. Users push up the balm from the bottom disc, adding a fun, interactive element.

Twist-Up Tubes: Combining convenience with eco-friendliness, these are similar to traditional plastic tubes but made from paper outer.

Moreover, we can customize the lids and bodies of paper tube packaging in various proportions to accommodate different capacity requirements, ensuring ease of use. Brands can also incorporate personalized printing designs to enhance the visual appeal.

Below are 3 examples designed in different ratio.

- Short cap long base

- Middle open type

- Long cap short base

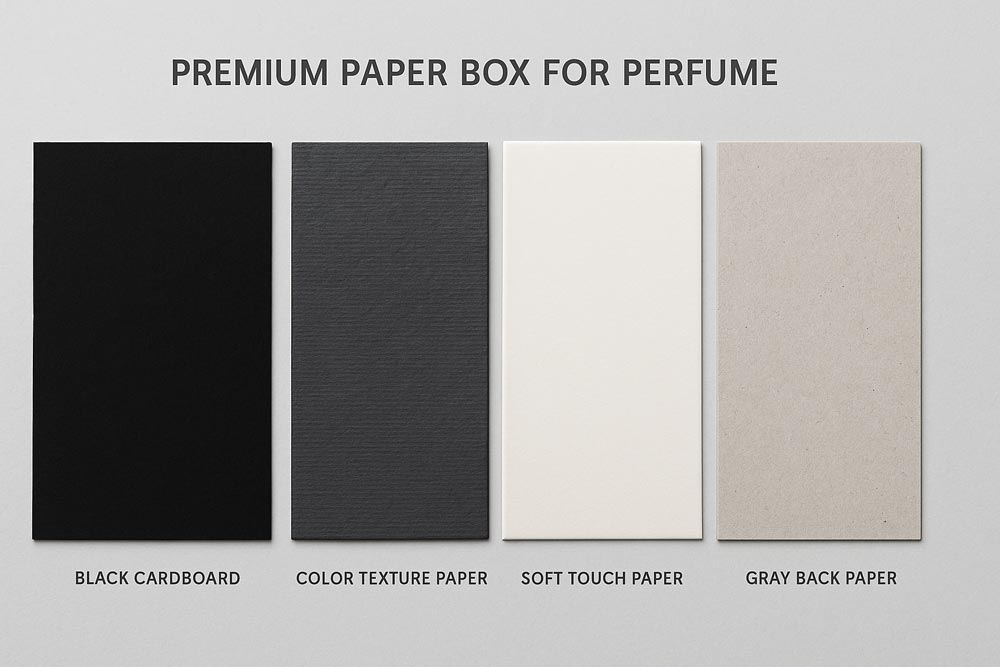

2.2. Material Selection:

Coated Paper (Copperplate Paper): Smooth and high-quality, perfect for vibrant and detailed printing. Ideal for a polished, premium look.

Kraft Paper: Rustic and eco-friendly, perfect for brands emphasizing natural and organic products.

Specialty Papers: Textured, recycled, or custom-dyed papers add a unique feel and aesthetic.

2.3. Size and Capacity Design:

Common weights of lip balm on the market typically include the following:

- 4 grams (0.14 oz)

- 5 grams (0.17 oz)

- 7 grams (0.25 oz)

- 10 grams (0.35 oz)

We can customize the sizes and dimensions of lip balm paper tube packaging to meet these capacity requirements. While one import point we must remind you that, do care about the user experience.

User Convenience: Ensure the diameter is at least 18mm so users can easily push the balm up with their fingers. Customize the height to match your product’s volume for a compact yet sufficient design. A too small diameter like 12mm will get hard for finger to fit in.

2.4. Printing and Branding:

2.4.1 Digital Printing

Digital printing offers flexibility and efficiency, making it ideal for short runs and personalized printing. Here are some ways to leverage digital printing to highlight your brand:

- Personalization: Use the flexibility of digital printing to personalize each batch or product. For example, print customers’ names or special messages on the packaging to enhance user experience and brand loyalty.

- Quick Time to Market: Digital printing eliminates the need for printing plates, reducing preparation time and allowing new products to be brought to market faster.

- High-Quality Images: Digital

printing can achieve high-quality image printing, ensuring that the

brand’s visual image is exquisite and professional.

2.4.2 Four-Color Printing (CMYK)

Four-color printing is suitable for large-scale production and can achieve rich color effects. Here are some ways to use four-color printing to highlight your brand:

- Colorful Designs: Utilize the advantages of four-color printing to design vibrant, eye-catching packaging that enhances the brand’s visual impact.

- Brand Consistency: Four-color printing ensures color consistency across large production runs, maintaining a uniform brand image.

- Complex Patterns and Gradients: Four-color printing can easily achieve complex patterns and gradient effects, adding visual layers and artistic appeal to the packaging.

2.4.3 Hot Stamping and Foil Embossing: Adds a luxurious touch with metallic or glossy effects, making your brand logo stand out.

2.4.4 Embossing and Debossing: Adds texture and a premium feel, highlighting key brand elements.

By carefully selecting materials, structural designs, and printing techniques, you can create paper lip balm packaging that not only protects your product but also enhances your brand image and appeals to eco-conscious consumers.

2.5 Brand Example: How Burt's Beese Highlight Brand on Lip Balm Paper Tube?

Creating standout paper lip balm packaging is essential to reflect your brand’s unique identity and commitment to sustainability. Let’s use Burt’s Bees as a case study to illustrate how to effectively design and customize your packaging.

- Structural Design Choice

Burt’s Bees uses a push-up tube design for their paper lip balm packaging. This structure allows users to easily push the balm up from the bottom, providing a simple and intuitive user experience.

- Material Selection

Burt’s Bees often uses kraft paper for its natural and organic look, aligning with the brand’s emphasis on natural ingredients and sustainability.

- Size and Capacity Design

Burt’s Bees lip balms provide 2 capacities to choose from, 0.13oz and 0.34oz, which are popular capacity on market. And they custom an outer display packaging for each unit, which has ensured their packaging is compact and portable, fitting easily in pockets or bags.

- Printing and Branding

Burt’s Bees uses high-quality printing for vibrant and clear branding. It uses earth tones and natural colors that reflect their commitment to nature and sustainability. The packaging features a minimalist design focusing on essential brand elements. And we do not see any foiling and other finishes on its printing, Burt’s Bees keeps it simple, focuses on straightforward printing, it believe simple is beauty.

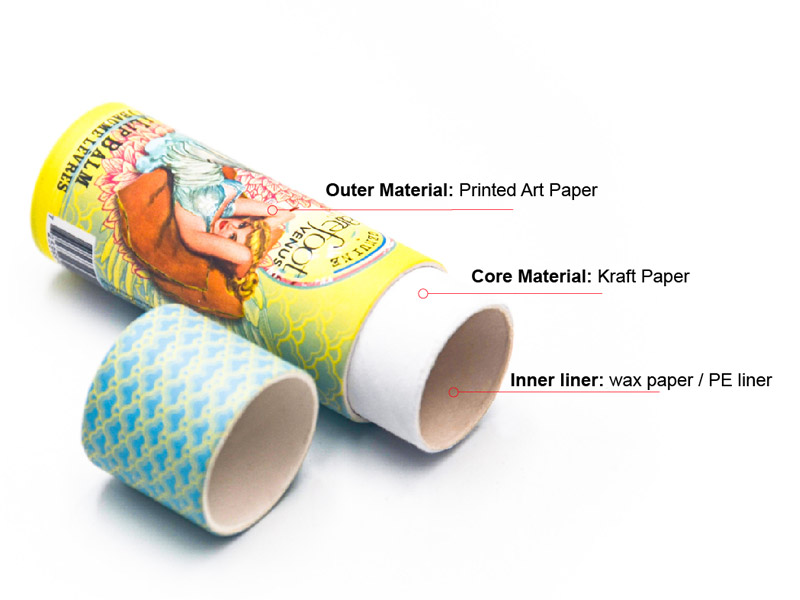

Chapter3: Different Paper Materials for Lip Balm Tube Packaging: Printing Methods and Their Effects

Choosing the right paper material for your lip balm packaging is crucial as it affects the printing method and the overall look and feel of the packaging. Here’s a fun and lively overview of different paper materials (coated paper, kraft paper, specialty paper) and the printing methods best suited for each, along with the effects they produce.

3.1. Coated Paper (Copperplate Paper)

Description:

- Coated paper, also known as copperplate paper, has a smooth, glossy, or matte finish due to a coating of clay or other substances. This surface allows for high-quality printing with vibrant colors and fine details.

Printing Methods:

- Digital Printing: Perfect for small runs and personalized prints. Digital printing works well on coated paper, delivering high-quality images and text.

- Four-Color Printing: Ideal for high-quality, full-color images and complex designs. Four-color printing produces vibrant colors and fine details on coated paper.

- Spot Color Printing: Great for maintaining brand color consistency. Spot color printing ensures accurate and stable color representation on coated paper.

Effects:

- High Gloss: Perfect for brands looking for a polished, premium look. It enhances the color vibrancy and gives the packaging a sleek finish.

- Matte Finish: Offers a sophisticated and subtle appearance, reducing glare and making the text easier to read.

- Detailed Graphics: Ideal for complex designs, high-resolution images, and intricate patterns.

3.2. Kraft Paper

Description:

- Kraft paper is made from wood pulp and has a natural, rustic appearance. It is often brown but can also be bleached to create a white version. Kraft paper is strong, durable, and eco-friendly.

Printing Methods:

- Spot Color Printing: Necessary for achieving stable colors on kraft paper. Due to the rough texture, spot color printing ensures even coverage.

- Steps: First, apply a full spot color base using a UV machine, then proceed with further printing and processing.

- Because of its multiple printing, unit cost is a bit more expensive than coated paper printing.

- Hot Stamping: Ideal for simple designs, adding metallic or glossy varnishing effects to enhance the packaging’s visual appeal, It also make packaging look high level.

Effects:

- Natural Look: Emphasizes the eco-friendly aspect of your brand, perfect for natural or organic products.

- Rustic and Earthy: Provides a warm, down-to-earth feel that appeals to environmentally conscious consumers.

- Textured Print: The rough texture of kraft paper adds depth and character to the print, making simple designs more impactful.

3.3. Specialty Paper

Description:

- Specialty paper includes a wide range of unique papers such as textured paper, recycled paper, metallic paper, and custom-dyed paper. These papers are designed to stand out with unique finishes and textures.

Printing Methods:

- Hot Stamping: Adds metallic or glossy effects using foil. It’s great for adding luxurious accents and highlighting brand elements.

- Embossing/Debossing: Creates raised or recessed designs, adding a tactile element that enhances the feel of the packaging.

- Digital Printing: Suitable for smaller runs and personalized designs. It works well with many types of specialty paper but may require adjustments for unique textures.

Effects:

- Textured Finish: Adds a unique tactile experience, making the packaging more engaging.

- Metallic and Glossy Accents: Elevate the packaging with luxurious touches, perfect for premium products.

- Custom Colors: Custom-dyed paper can match your brand’s color scheme exactly, making your packaging more cohesive and distinctive.

Choosing the right combination of paper material and printing method can significantly impact the look and feel of your lip balm packaging. And by understanding the strengths and effects of each paper material and printing method, you can create packaging that not only protects your product but also effectively communicates your brand values and appeals to your target audience.

Chapter4: The Custom Paper Lip Balm Packaging Process: From Concept to Delivery

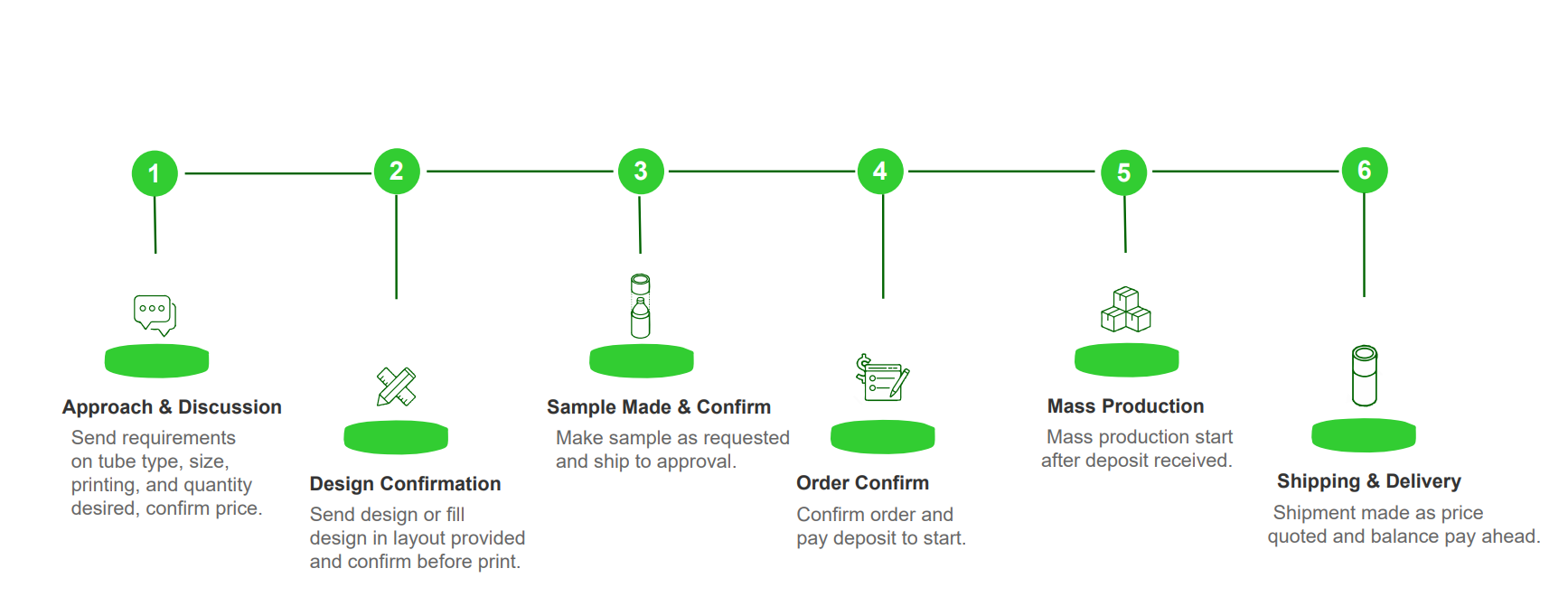

Creating custom paper lip balm packaging is an exciting journey! Here’s a lively breakdown of the process from initial communication to final delivery, ensuring your brand’s packaging is perfectly tailored to your needs.

- Approach and Discussion: Gathering and confirming all necessary details.

- Design Confirmation: Creating and refining design drafts until final approval.

- Sample Made and Confirmation: Producing and approving a prototype.

- Order confirmation: Confirm order and pay deposit to start.

- Mass Production: Manufacturing the packaging in bulk.

- Shipping and Delivery: Ensuring the final product reaches you safely and on time.

Chapter 5: How to Cut Costs on Custom Paper Lip Balm Packaging

Reducing costs on custom paper lip balm packaging can be a fun and rewarding process! Here are some easy and effective strategies to help you save money without compromising on quality.

5.1. Optimize Material Selection

Choose the Right Materials: Opt for more economical and eco-friendly materials like coated paper or kraft paper instead of pricier specialty paper.

Maximize Material Use: Design your packaging to minimize waste and make the most of the materials.

Compare Suppliers: Shop around to find suppliers who offer the best value for your money.

5.2. Simplify the Design

Keep it Simple: Avoid complicated designs and decorations that can drive up printing and production costs. With each additional process, the cost will correspondingly increase.

Standard Sizes: Stick to standard packaging sizes to avoid the extra costs of custom molds and production adjustments. And for products with similar sizes, customizing a single size of paper tube packaging, rather than separately customizing different sizes, can effectively reduce costs.

5.3. Bulk Production

Order in Bulk: Larger orders can help spread out the costs, making each unit cheaper.

Share Production Batches: Team up with other brands to share production batches and split the costs.

5.4. Optimize Production Processes

Choose Cost-Effective Printing Methods: Go for more affordable printing options like flexographic or digital printing instead of expensive spot color or foil stamping.

Streamline Processes: Cut out unnecessary production steps to save on processing costs.

5.5. Supply Chain Management

Optimize Shipping: Find the most cost-effective shipping methods and routes to reduce transportation costs.

Cut Out the Middleman: Work directly with manufacturers to avoid the extra markups from middlemen.

5.6. Long-Term Partnerships

Build Long-Term Relationships: Establish long-term partnerships with suppliers to get better prices and services. Plan and Order Ahead: Avoid last-minute orders that come with rush fees by planning and ordering in advance.

Chapter 6: The Impact of Printing Processes on Packaging Degradation

When considering the environmental impact of paper packaging for lip balm, it’s essential to understand how different printing processes and materials affect the degradation process. Here’s a breakdown of the key factors:

6.1. Degradation Process and Timeline of Paper Materials

Paper Material Degradation:

- Coated Paper: Degrades slower than uncoated paper due to the coating, which can be plastic-based, hindering microbial activity. Typically takes 3-6 months to degrade under composting conditions.

- Kraft Paper: More environmentally friendly and degrades faster, usually within 2-3 months under composting conditions.

- Specialty Papers: The degradation rate varies widely depending on the coatings and additives used.

6.2. Impact of Wax Paper/Oil-Resistant Paper/Poly-Coated Paper Linings

Wax Paper:

- Degradation: Wax-coated paper is partially biodegradable, but the wax can slow down the process.

- Environmental Impact: Natural waxes (like beeswax) are better for the environment compared to petroleum-based waxes.

Oil-Resistant Paper:

- Degradation: Typically coated with chemicals or plastic films to resist oil, slowing down degradation.

- Environmental Impact: These coatings can introduce pollutants into the soil if not properly managed.

Poly-Coated Paper:

- Degradation: Polyethylene coatings are non-biodegradable and significantly slow down the degradation process.

- Environmental Impact: These coatings can break into microplastics, causing environmental pollution.

6.3. Impact of Printing Inks

Traditional Inks:

- Degradation: Often contain heavy metals and other toxic substances that can leach into the soil during degradation.

- Environmental Impact: These inks can harm soil quality and microbial activity, delaying the degradation process.

Soy-Based Inks:

- Degradation: More environmentally friendly and degrade faster without leaving harmful residues.

- Environmental Impact: Generally safer for the environment, supporting quicker and more complete degradation of paper.

6.4. Impact of Laminated Outer Layers

Plastic Lamination:

- Degradation: Creates a barrier to microbial activity, making the paper nearly non-biodegradable.

- Environmental Impact: Can lead to plastic pollution if not recycled properly.

Biodegradable Lamination:

- Degradation: Made from materials like PLA (polylactic acid) which are compostable and degrade faster.

- Environmental Impact: More eco-friendly option, though still requires industrial composting facilities for proper degradation.

6.5. Effects of Various Printing Techniques

Foil Stamping:

- Degradation: Foil elements do not biodegrade and can interfere with the recycling process.

- Environmental Impact: Adds to landfill waste if not separated before recycling.

UV Coating:

- Degradation: UV coatings are generally non-biodegradable and slow down the overall degradation process.

- Environmental Impact: Can release harmful chemicals during degradation.

Embossing and Debossing:

- Degradation: These techniques have minimal impact on the degradation process as they do not add non-biodegradable materials.

- Environmental Impact: Environmentally friendly as long as no additional coatings are used.

By choosing the right materials and processes, brands can ensure their packaging is not only appealing but also environmentally responsible.

All Paper Tube company is committed to developing eco-friendly packaging solutions. In addition to customizing paper tube packaging to meet customer specifications, we prioritize environmental protection at every stage of production. The customized lip balm paper tubes use natural wax paper liners that are oil- and moisture-resistant, and the outer paper is printed with eco-friendly soy-based ink to minimize environmental impact.

6.6 How to Customize a 100% Recyclable and Biodegradable Paper Tube Packaging

To create a paper tube packaging that is 100% recyclable and biodegradable, careful selection of materials and processes is essential. Here are some suggestions:

- Material Selection: Choose kraft paper as the main material and use plant-based glue.

- Design Simplification: Design a simple sliding lid structure to ensure good user experience.

- Eco-Friendly Printing: Use soy-based ink for flexographic printing.

- Non-Plastic Coating: Avoid plastic lamination and choose natural plant oil as a protective coating.

By following these methods and steps, you can successfully customize a fully recyclable and biodegradable paper tube packaging, highlighting your brand’s commitment to environmental protection.

Chapter 7: Recycling and Reusing Paper Tube Lip Balm Packaging

7.1 From the Consumer's Perspective

7.1.1. Convenience and Environmental Awareness

As a consumer, using paper tube lip balm packaging is not only simple and convenient but also allows you to make eco-friendly choices in your daily life. Here are some ways to recycle and reuse paper tube lip balm packaging:

- Disposal after Use:

- Once the lip balm is finished, easily toss the paper tube packaging into your home recycling bin.

- Ensure there is no remaining balm in the packaging to avoid contaminating other recyclables.

- How to Handle the Packaging:

- At home, sort the paper tube packaging separately from other recyclables.

- Learn about your community’s recycling program requirements to ensure proper disposal of paper packaging.

- Environmental Awareness:

- By participating in recycling, you help reduce the amount of waste in landfills.

- Support the use of renewable resources and protect the environment.

7.1.2. Participating in the Brand’s Eco-Friendly Initiatives

By recycling paper tube lip balm packaging, consumers can actively participate in the brand’s eco-friendly initiatives and feel connected to the brand’s green values:

- Enhancing Consumer Experience:

- Using products with eco-friendly packaging can enhance the shopping experience, making consumers feel they are contributing to environmental protection.

- Consumers can learn more about recycling and the brand’s environmental efforts through promotional materials and social media.

7.2 From the Brand's Perspective

7.2.1. Eco-Friendly Image and Market Competitiveness

As a brand, using recyclable paper tube lip balm packaging not only reduces environmental impact but also enhances the brand’s eco-friendly image and boosts market competitiveness:

- Enhancing Brand Value:

- Eco-friendly packaging communicates the brand’s commitment to the environment, increasing brand loyalty.

- In marketing campaigns, brands can highlight the benefits of eco-friendly packaging to attract environmentally-conscious consumers.

- Boosting Market Competitiveness:

- Using recyclable paper tube packaging can help brands stand out in the market, meeting the growing demand for eco-friendly products.

- Brands can collaborate with other environmental organizations or projects to enhance their influence through eco-friendly packaging.

7.3. Practical Steps for Recycling and Reusing

Brands can take the following steps to ensure the smooth recycling and reuse of paper tube lip balm packaging:

- Collaboration with Recycling Agencies:

- Partner with local recycling centers to ensure paper tube packaging can be smoothly recycled.

- Provide clear recycling guidelines to inform consumers on how to properly dispose of the packaging.

- Incentive Programs

Brands may offer recycling reward programs, such as points or discounts, to encourage consumers to participate in recycling.

- Optimizing Product Design:

- Consider recyclability during the product design phase, using simple, easy-to-disassemble structures and eco-friendly materials.

- Ensure that the printing and adhesives used on the packaging are eco-friendly and easily degradable.

- Promotion and Education:

- Use advertisements, social media, and information on product packaging to educate consumers on the proper methods of recycling paper tube packaging.

- Regularly publish the brand’s environmental actions and achievements to enhance consumer trust and support.

Chapter 8: Storage and Filling Considerations for Paper Lip Balm Packaging and Analysis of Melting Issues

To ensure the quality and performance of paper lip balm packaging and to address whether the melting of the balm is related to the paper tube packaging, please note the following storage and filling considerations:

8.1. Temperature and Humidity Storage Recommendations for Empty Paper Tubes

Temperature Control:

- Ideal Temperature: The ideal storage temperature for empty paper tubes should be maintained between 20-40°C (68-104°F).

- Avoid Extreme Temperatures: Avoid storing empty paper tubes in very hot or very cold environments to prevent deformation or damage to the paper material.

Humidity Control:

- Ideal Humidity: Relative humidity should be maintained less than 20%.

- Moisture Control: In humid environments, use desiccants or dehumidifiers to prevent the paper tubes from becoming soft or moldy due to moisture.

Storage Environment:

- Well-Ventilated: Ensure the storage area is well-ventilated to avoid odors and moisture buildup in enclosed spaces.

- Dust Protection: Use dust covers or storage bags to keep the paper tubes clean.

8.2.Temperature Recommendations for Filling the Balm

Appropriate Temperature:

- Melting Temperature: The melting temperature of the lip balm is usually between 60-80°C (140-178°F). During filling, keep the balm within this temperature range to ensure it flows smoothly into the paper tube.

- Cooling Time: After filling, allow the balm to cool naturally to room temperature to ensure it sets and stabilizes properly.

Filling Process:

- Even Heating: Ensure the balm is heated evenly to avoid localized overheating, which can lead to inconsistent texture.

- Filling Speed: Control the filling speed to prevent the paper tube from deforming due to rapid heat exposure, or the balm from solidifying unevenly if filled too slowly.

8.3. Relationship Between Balm Melting and Paper Tube Packaging

Temperature Sensitivity:

- Environmental Temperature: Paper lip balm packaging is sensitive to environmental temperature. In high temperatures, the paper tube may soften, affecting the structural stability of the packaging.

- Filling Temperature: During the filling process, the paper tube needs to withstand a certain amount of heat. High-quality paper tubes can remain stable at the balm’s melting temperature without deforming or breaking.

Paper Tube Selection:

- High-Temperature Tolerance: Choose paper materials with good high-temperature tolerance to ensure the paper tube doesn’t deform during the filling process.

- Moisture Resistance: The inner wall of the paper tube can be treated with a moisture-resistant coating or lined with wax to prevent the oil in the balm from penetrating and causing the tube to deform.

Balm Formula:

- Stable Formula: Ensure the lip balm formula is stable and not easily affected by temperature changes to avoid deformation or leakage when the balm melts.

- Storage Conditions: Advise users to store the lip balm in a cool, dry place, avoiding high temperatures and direct sunlight to extend product life.

8.4 User Case Analysis

A user conducted a test by placing a filled paper tube lip balm in a high-temperature car trunk and found that the lip balm melted and leaked out of the paper tube. This situation is primarily due to the following reasons:

- High-Temperature Environment: Lip balm primarily consists of wax, oil, and pigments, which melt in high temperatures. The temperature in a car trunk during summer can exceed 40-50°C (104-122°F), which is well above the melting point of lip balm (usually between 60-70°C).

- Insufficient Sealing: The paper tube packaging may deform at high temperatures, reducing its sealing performance and allowing the melted balm to leak out.

- Material Characteristics: High temperatures accelerate the penetration of oils from the balm into the paper material, causing the tube to soften or lose its structural integrity.

By following proper storage and filling methods, you can effectively ensure the quality and performance of paper lip balm packaging. Controlling temperature and humidity, choosing the right paper tube materials, and ensuring the stability of the balm formula are crucial for maintaining product quality. In high-temperature environments, the melting of the lip balm is mainly due to excessive heat. The sealing and material selection of the paper tube also play a role. To avoid such issues, users should store lip balm in cool environments and consider improvements in packaging design and balm formulation to enhance stability in various conditions.

Conclusion

It would be best if you worked with a professional lip balm paper tube packaging factory. They will help you get quality lip balm paper packaging and eco-friendly custom solutions and affordable prices.

Contact us if you have any questions about custom paper tube on lip balm, deodorant too.