When you begin the journey of developing bespoke packaging, the first question is almost always about the cost. However, because round packaging is a highly modular and tailorable solution, custom paper tube pricing is influenced by a variety of technical specifications. Providing a “rough estimate” can be difficult without understanding the finer details of your brand’s requirements.

To help you navigate the quoting process and optimize your packaging budget, we have outlined the six most critical factors that determine the final investment of your project.

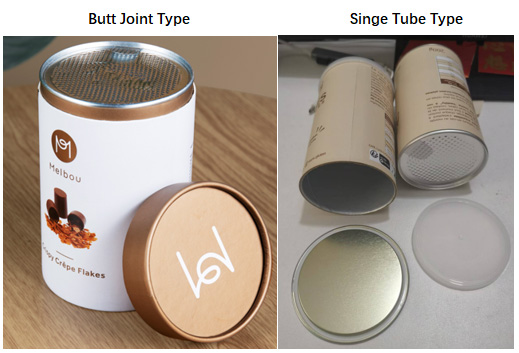

1. Structural Style and Complexity

The engineering of a paper tube dictates the amount of labor and the type of machinery required.

Two-Piece Telescopic Tubes: The most common retail style with a cap and a base. It is efficient to produce and offers a classic unboxing experience.

Three-Piece “Butter-joint” Tubes: These feature an internal “neck” so the lid and base meet seamlessly. This style requires an extra component and more precise manual assembly, which naturally elevates the custom paper tube pricing.

Single-Piece Tubes: Typically used for mailing or industrial purposes, these are the most budget-friendly but offer less “brand ceremony.”

2. Dimensions and Material Volume

It is an industry standard: larger tubes require more raw paperboard and liner material. However, size influences cost in more ways than just surface area.

Standard vs. Extreme Sizes: Extremely large diameters or very tiny, intricate tubes may require specialized tooling or slower production speeds.

Wall Thickness: If your product is heavy (like a glass bottle), you may need a thicker, reinforced wall, which adds to the material cost per unit.

3. The Choice of Outer Wrap and Liners

What you see on the surface and what lines the interior play a massive role in custom paper tube pricing.

Art Paper vs. Specialty Paper: Standard coated art paper is excellent for high-resolution 4-color printing. However, if your brand demands the tactile luxury of Specialty Paper (linen texture, metallic sheen, or black kraft), the cost increases.

The Printing Challenge: Specialty papers often have non-porous or textured surfaces that do not take standard ink well. To achieve a high-quality finish on these materials, we must use UV Printing, which involves specialized machinery and longer drying times, impacting the final quote.

4. Printing Techniques and Embellishments

The visual complexity of your artwork is a primary driver of cost.

CMYK vs. Pantone: Standard 4-color (CMYK) printing is cost-effective. If your brand guidelines require a specific Pantone (Spot Color) match to ensure global consistency, this requires custom ink mixing and dedicated press runs.

Premium Finishes: Embellishments like Hot Foil Stamping (Gold/Silver), Spot UV, or Embossing require custom-made zinc or copper plates. Each additional process adds a “pass” through the production line, which is a key variable in custom paper tube pricing.

5. Order Quantity and SKU Complexity

In the packaging industry, economies of scale are highly significant.

Setup Costs: Every custom run requires hours of machine calibration and plate mounting. When you order 5,000 units, these “sunk costs” are spread thin, resulting in a much lower unit price compared to an order of 500 units.

Multiple Variations: If you have four different flavors or scents (SKUs), even if the tube size is the same, each variation requires new plates and machine stops. More SKUs lead to higher production waste, which is reflected in the pricing.

6. Personalized Functional Customizations

The final “wow” factors often involve manual craftsmanship.

Die-cut Windows: Adding a window so customers can see the product involves a custom die-cutting tool and the manual application of a transparent PET film.

Functional Add-ons: Incorporating silk ribbons, pull-tabs, or custom-shaped foam/paper inserts increases the “hand-finishing” time. Because these steps cannot be fully automated, they add a premium to the custom paper tube pricing.

How to Request an Accurate Quote

To receive a precise and competitive quote from our team, we recommend providing the following details in your initial inquiry:

Dimensions: Internal Diameter x Internal Height (mm).

Style: 2-piece, 3-piece, or custom structure.

Quantity: Total volume and number of design variations (SKUs).

Material/Finish: Standard art paper or specialty paper? Any foil or UV requirements?

Understanding the nuances of custom paper tube pricing allows you to make informed decisions that balance brand impact with financial efficiency. Our team is always available to suggest “smart alternatives”—such as switching a specialty paper for a clever printing effect—to help you achieve a premium look within your target budget.

Ready to bring your vision to life? Contact us today for a detailed consultation!