The journey to perfect coffee bean storage paper tubes begins with understanding a critical scientific dilemma. Freshly roasted coffee beans release significant amounts of carbon dioxide – approximately 4-8 liters of gas per kilogram of beans over several days. This “degassing” process creates substantial internal pressure that can burst conventional packaging. However, the same packaging must simultaneously prevent oxygen from entering, as exposure to just 2% oxygen can degrade coffee quality by 20% within 10 days. This delicate balance between releasing CO₂ while blocking O₂ represents the fundamental challenge in whole bean coffee packaging. The solution lies in specialized coffee storage tube designs that actively manage this gas exchange process while maintaining complete barrier protection.

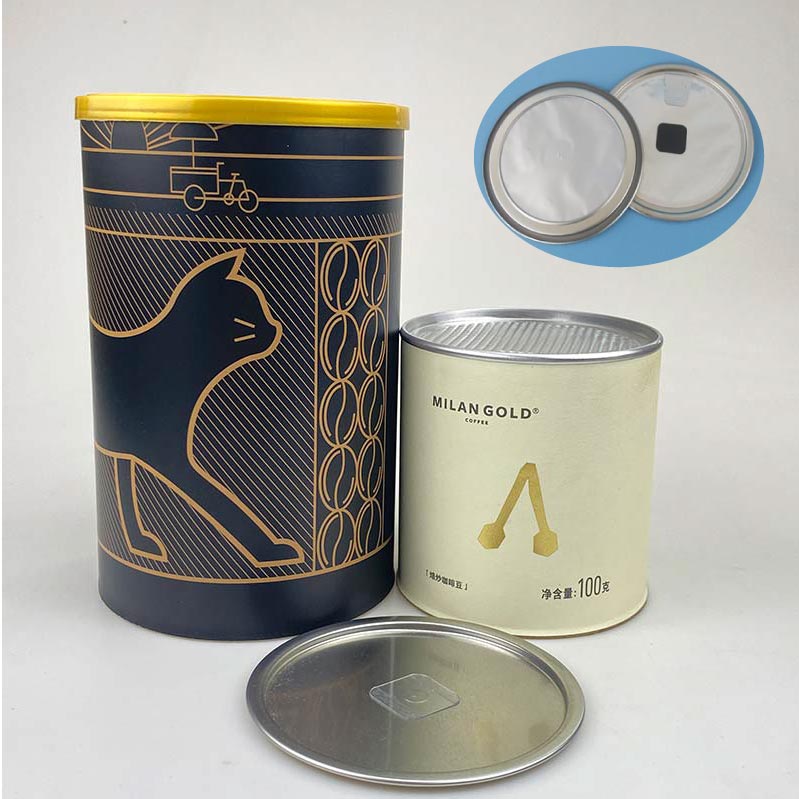

The Intelligent Solution: One-Way Degassing Valves in Coffee Storage Tubes

The coffee degassing valve represents one of the most crucial innovations in coffee packaging technology. These sophisticated one-way valves are precision-engineered to allow CO₂ to escape while preventing oxygen from entering. Typically constructed with multiple polymer layers and specialized membranes, quality coffee degassing valves can release up to 5 liters of CO₂ per day while maintaining an oxygen barrier efficiency of 99.9%. When integrated into coffee bean storage paper tubes, these valves actively protect your beans during the critical first 7-10 days post-roasting when gas emission is most intense. The visible presence of a coffee degassing valve also serves as a trust signal to consumers, demonstrating your commitment to proper coffee preservation.

Maximum Protection: Aluminum Foil Liners for Whole Bean Coffee Packaging

While valves manage gas exchange, aluminum foil liners provide the essential barrier foundation in premium coffee bean storage paper tubes. High-quality foil laminates used in professional coffee storage tube applications typically achieve oxygen transmission rates below 0.5 cc/m²/day and water vapor transmission rates under 0.3 g/m²/day. This level of protection ensures that coffee oils don’t become rancid and delicate aromatic compounds (including over 800 volatile organic compounds that create coffee’s complex flavor profile) remain intact. The foil barrier in whole bean coffee packaging also blocks UV light, which can accelerate the breakdown of essential coffee compounds. Independent studies confirm that proper foil-lined packaging can preserve coffee freshness for up to 12 months when combined with correct valve technology.

Professional Sealing: Machine-Sealed Tops for Optimal Freshness

The integrity of any coffee storage tube depends heavily on its sealing methodology. Professional machine sealing creates a hermetic environment that supplementary technologies like valves and foil layers require to function effectively. Industrial heat sealing equipment can achieve seal strengths of 3-5 Newtons per 15mm width, ensuring complete protection during shipping and storage. In optimal whole bean coffee packaging configurations, one end is factory-sealed while the other remains open for filling before final closure. This approach guarantees that the internal environment remains controlled from production through consumption. The machine-sealed tops on coffee bean storage paper tubes provide the crucial final layer in a comprehensive protection system, working in concert with valves and foil barriers.

The Complete System: How All Components Work Together

The true effectiveness of coffee bean storage paper tubes emerges when all components function as an integrated system. The aluminum foil liner blocks external oxygen (99.9% efficiency), the coffee degassing valve manages internal CO₂ pressure (releasing 5+ liters daily), and the machine-sealed tops maintain overall package integrity. This synergistic approach creates what industry experts call “active packaging” – containers that don’t merely hold products but actively participate in preserving quality. Premium coffee storage tube systems can maintain oxygen levels below 1% internally while managing the substantial gas output from freshly roasted beans. This comprehensive protection system ensures that consumers experience the coffee exactly as the roaster intended.

Perfect Sizing: Matching Coffee Storage Tubes to Your Bean Volume

Proper sizing is crucial for effective whole bean coffee packaging. Standard 12-ounce (340g) packages require approximately 450-500 cubic centimeters of internal volume to accommodate both beans and necessary headspace for proper degassing. Our coffee bean storage paper tubes are precision-engineered to match industry standards while accounting for bean density variations. For local roasters, we offer custom sizing options ranging from 4-ounce sample packages to 5-pound bulk containers. The relationship between package volume and coffee quantity directly impacts valve performance and freshness preservation – too much headspace accelerates staling, while insufficient space inhibits proper degassing. Our technical team can help optimize your coffee storage tube dimensions for your specific product line.

Custom Solutions for Local Roasters: Small-Batch Coffee Packaging

Local roasters face unique challenges in whole bean coffee packaging, often requiring smaller production runs of 500-5,000 units with flexible customization options. Our coffee bean storage paper tubes are specifically designed to meet these needs, offering:

Minimum order quantities as low as 500 units

Rapid 10-15 day production turnaround

Custom diameter and height specifications

Flexible branding and design options

Valve and component customization

We understand that local roasters need coffee storage tube solutions that scale with their business while maintaining the same quality standards as large commercial operations. Our specialized small-batch manufacturing process ensures that emerging brands can access the same advanced packaging technology as industry leaders.

Conclusion: Engineering Perfect Coffee Preservation

The science of coffee bean storage paper tubes involves careful balancing of multiple technical factors – from gas management and oxygen barriers to structural integrity and consumer convenience. By integrating one-way coffee degassing valves with aluminum foil liners and professional machine sealing, roasters can create packaging that actively participates in quality preservation rather than simply containing products.

At AllPaperTube packaging, we specialize in developing customized coffee storage tube solutions that address the specific needs of both commercial operations and local artisans. Our technical team can help you optimize your whole bean coffee packaging to ensure your product reaches consumers at peak freshness.

Contact us today to discuss your coffee packaging requirements and discover how our integrated tube solutions can enhance your product’s shelf life while strengthening your brand presence in the competitive coffee market.