Sustainable packaging is no longer just a trend—it’s a consumer expectation. Studies show that 73% of global consumers prefer brands with sustainable packaging (Nielsen, 2024). In this paper tube packaging guide, we’ll explore how paper tube packaging fits this demand perfectly, being biodegradable, recyclable, and often made from post-consumer materials. Compared to plastic, paper tubes significantly reduce environmental impact while enhancing brand credibility.

Why Choose Paper Tube Packaging?

Paper tubes combine strength, versatility, and premium aesthetics. Unlike rigid boxes or plastic containers, the cylindrical design optimizes material use and protection. They are ideal for food powders, cosmetics, clothing, and even fragile items. This paper tube packaging guide will walk you through types, materials, customization options, and industry applications to help you make the best choice.

Chapter 1: Understanding Paper Tube Fundamentals

Materials That Make the Tube

Paper tubes are primarily made from:

Kraft Paper: Durable and eco-friendly; used in food and shipping.

Whiteboard/Greyboard: Smooth surface for premium printing; ideal for cosmetics.

Recycled Paper: Eco-conscious choice; slightly less rigid but cost-effective.

Key Terms Explained

Inner Liner: Protects against moisture or oils.

Wall Thickness (GSM): Determines rigidity (typically 200–800 GSM).

End Caps: Plastic, metal, cork, or paper; affects resealability and aesthetics.

Chapter 2: A Deep Dive into Paper Tube Types & Materials

By Material Composition

Kraft Paper Tubes: Durable, eco-friendly, used for teas, snacks, or shipping.

Whiteboard/Greyboard Tubes: Smooth finish for high-quality printing; used for cosmetics and gifts.

Recycled Material Tubes: Brands focusing on sustainability often prefer these.

kraft paper tube whiteboard tube

whiteboard tube

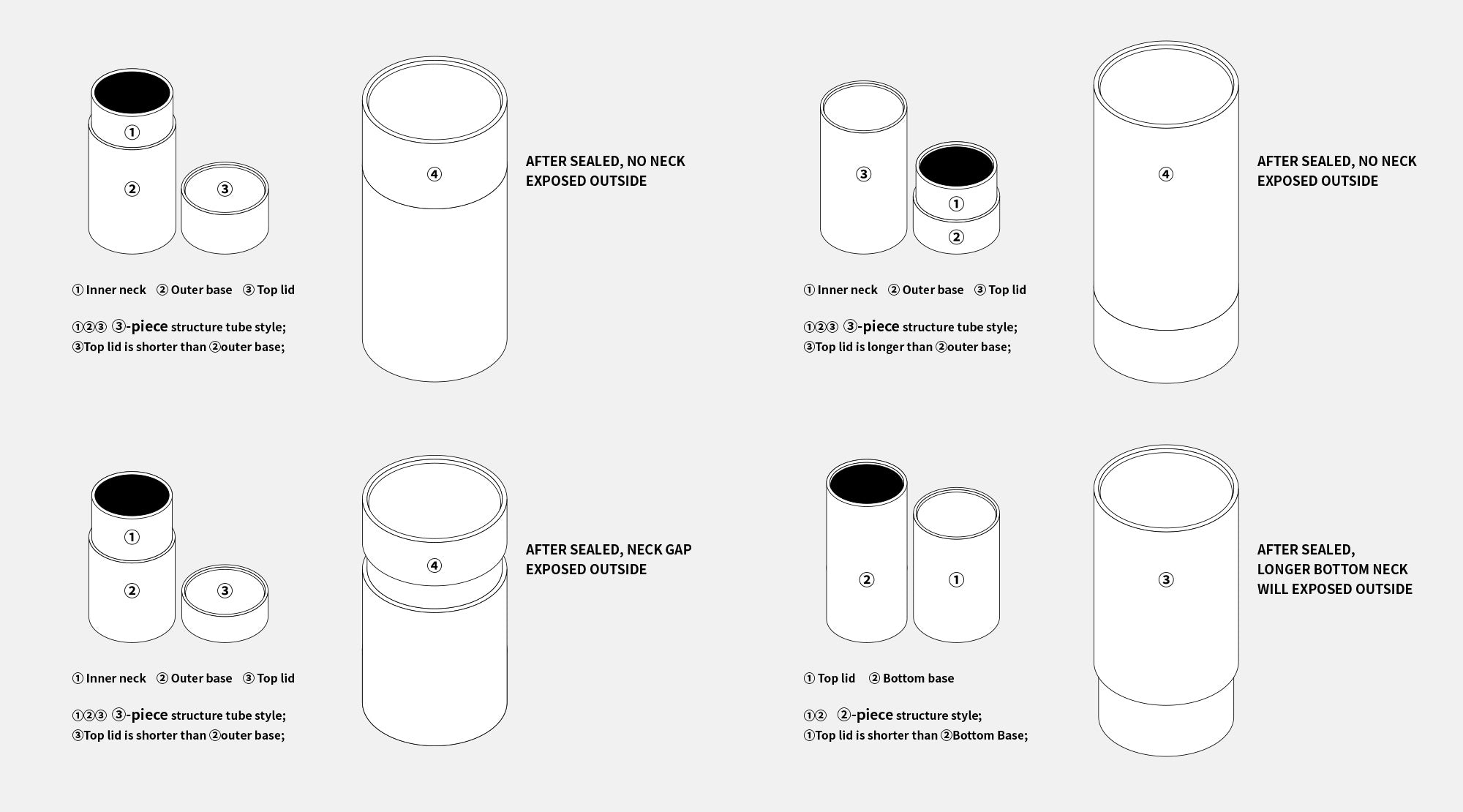

By Structural Type – A paper tube packaging guide for business

Single-Unit Tubes: Simple cylinders for powders, snacks, or posters.

Telescopic/Expandable Tubes: Adjustable height for multi-size products or gift sets.

Butt-Joint Tubes: Extra durability for heavy or long items.

paper tube packaging guide infographic

Special Function Types

Window Tubes: Transparent panel to display contents, ideal for candles or candies.

Shaker Top Tubes: Paper made or aluminum made shaker top for fine powder or spices to despens.

Bottom Push-Up Tubes: Great for lip balms or solid cosmetics; reduces waste.

Child-Safe Caps: Ensures tamper-proof closures for supplements, chemicals, or cosmetics.

Chapter 3: The Designer’s Toolkit: Finishes & Customization

Printing & Branding Options

UV Offset Printing: Vibrant, durable colors for luxury packaging.

Flexographic Printing: Cost-effective for bulk production.

Digital Printing: Short runs with complex designs, variable data possible.

Hot Foil Stamping: Adds metallic accents for premium appeal.

Surface Treatments

Embossing/Debossing: Adds tactile luxury to logos or patterns.

Spot UV Coating: Highlights specific elements like logos or text.

Matte/Gloss Laminates: Matte for premium feel, gloss for shine.

Soft-Touch/Anti-Scratch Films: Enhances user experience, common in cosmetics.

End Caps & Internal Options

Cap Types: Plastic, metal, cork, paper push-on, or twist-off.

Custom Inserts: EVA or foam trays for fragile items.

Inner Bags: Essential for powders or moisture-sensitive items.

Chapter 4: Unmatched Versatility: Industry Use Cases

Food & Beverage

Paper tubes are used for teas, coffee, protein powders, and dried snacks. Airtight liners maintain freshness. Brands replacing plastic tubs with paper tubes can reduce plastic use by up to 80%.

Beauty & Skincare

Lip balms, deodorants, and solid lotions use push-up tubes. Luxury brands also emboss logos or add foil stamping for premium appearance.

Retail & E-Commerce

T-shirts, scarves, and gifts can be shipped in paper tubes for stacking efficiency and enhanced unboxing experience.

Printing & Publishing

Posters, maps, or artwork fit perfectly in sturdy paper tubes, preventing bending or damage.

Industrial & Logistics

Paper tubes are used for transporting powders, small parts, or fragile components in warehouses.

Chapter 5: The Sustainable Choice: Environmental Credentials

Biodegradable & Recyclable

Most paper tubes are recyclable; biodegradable options degrade in 6–12 months.

Sourcing & Certifications

FSC or PEFC-certified tubes ensure sustainable forestry. Post-consumer recycled content further reduces environmental impact.

Reducing Carbon Footprint

Paper tubes consume up to 60% less energy than plastic alternatives and their lighter weight reduces shipping emissions.

Chapter 6: How to Source & Specify Your Paper Tubes

Finding Reliable Suppliers

Look for manufacturers experienced in custom paper tube packaging, who offer guidance on materials, printing, and certifications.

Specification Guidelines

Decide on:

Material type & thickness

Tube diameter & height

End cap type & finish

Inserts or inner bags

Ordering Process

Request sample approval

Approve final design proof

Confirm production timeline, shipping, and quality checks

Conclusion: The Future of Paper Tube Packaging

Innovation Trends

Smart packaging (QR codes, NFC chips)

Modular tubes for multi-product bundles

Advanced barrier coatings for moisture or oil resistance

Suggested Image: Futuristic tube concept image.

Why Paper Tubes Will Endure

Paper tube packaging offers sustainability, versatility, and premium aesthetics, making it a lasting solution for brands across industries. It is more than a container—it is a brand statement.

All Paper Tube specializes in custom paper tube packaging that fits your products and brand perfectly. Backed by years of manufacturing experience, we offer expert guidance and reliable solutions to create sustainable, high-quality packaging that meets your business needs.

Contact a packaging specialist now