Introduction: The Importance of Sealed Packaging in the Food Industry

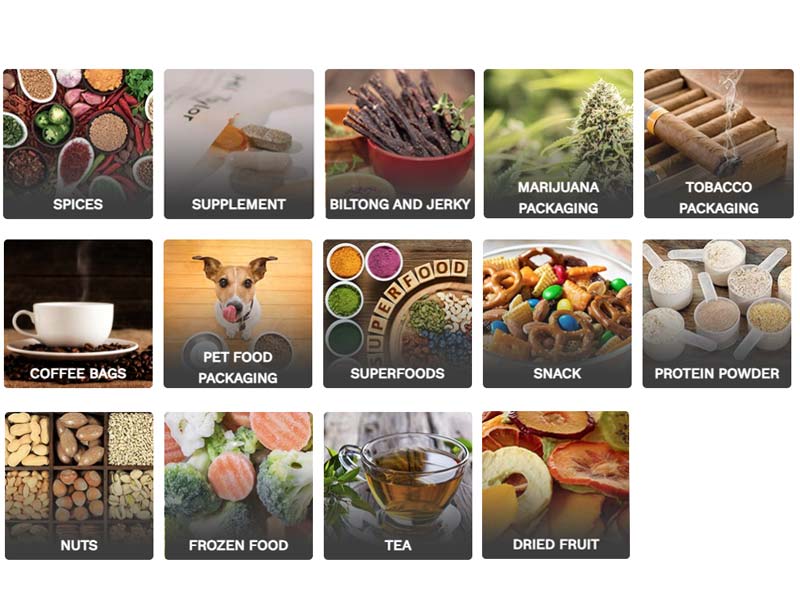

In today’s market, food manufacturers and brands—especially those in areas like puffed foods, nuts, snacks, dried fruits, and pet foods—are increasingly focused on sustainable packaging solutions. These companies aim to use eco-friendly materials while ensuring their packaging meets strict food-sealing standards. This rising demand has made composite cans a popular choice due to their environmental advantages and effectiveness in food storage. However, brands committed to eco-friendly packaging often struggle to find reliable sealing solutions for composite cans.

This article aims to assist by providing an overview of six leading Chinese manufacturers of can sealing machine, each offering machines specifically designed for sealing composite cans, tin cans, and glass jars. With these options, brands can discover the perfect solution to fulfill both their sustainability and packaging needs.

1. Levapack

Company Overview: Levapack specializes in manufacturing can sealing machines, including filling machines, capping machines, and labeling machines tailored for the food and beverage industries. They focus on providing customizable solutions to enhance operational efficiency in canning processes.

Established: 2008

Location: Guangzhou, Guangdong Province, China

Scale: Operates from a 4,000 square meter factory with a production capacity of over 80 units monthly.

Main Products: Can sealing machines, including can filling machines and sealing machines.

Export Data: Exports to various international markets, particularly in Europe, North America, and South America.

Website: levapack.com

2. Zhangjiagang King Machine Co., Ltd

Company Overview: This company specializes in manufacturing beverage machinery, particularly filling machines for various types of beverages. They emphasize quality and innovation in their equipment.

Established: 2009

Location: Zhangjiagang City, Jiangsu Province, China

Scale: Over 15 years of experience with substantial operations serving various countries.

Main Products: Beverage machinery, including filling lines for water, juice, and carbonated drinks.

Export Data: Exports internationally to North America, Europe, and Southeast Asia.

Website: king-machine.com

3. Hefei Zhongchen Light Industrial Machinery Co., Ltd

Company Overview: Specializes in the design and manufacturing of liquid filling machinery, including bottling and beverage machines. Recognized as a key enterprise in the Chinese liquid filling equipment industry.

Established: 2002

Location: Hefei, Anhui Province, China

Scale: Operates a large facility covering 16,000 square meters with between 101 and 500 employees.

Main Products: Liquid filling machines, bottling machines, beverage processing equipment (including beer can sealing machine).

Export Data: Exports to various international markets with a strong presence in the beverage sector.

Website: ahzhonghong.en.made-in-china.com

4. Shanghai iPanda Intelligent Machinery Co., Ltd

Company Overview: Focuses on manufacturing packaging equipment for various industries. They offer complete production lines that include filling machines, capping machines, and labeling machines.

Established: 2010

Location: Shanghai, China

Scale: Information not specified.

Main Products: Filling machines, capping machines, labeling machines, packaging machines.

Export Data: Products are exported to multiple regions including North America, South America, Eastern Europe, and Southeast Asia.

Website: shhipanda.com

5. Nanjing Light Industrial Machinery Group

Company Overview: A leading manufacturer specializing in canning machinery for the food and beverage processing industries. They focus on high-quality industrial equipment.

Established: 2003

Location: Nanjing, Jiangsu Province, China

Scale: Employs over 6,000 people and operates on a large scale focusing on industrial equipment manufacturing.

Main Products: Filling machines for carbonated beverages, beer production equipment, juice manufacturing equipment.

Export Data: Exports primarily to the USA, UK, and other regions in Europe.

Website: nanjiangmachine.com

6. Jinrong Machinery Co., Ltd

Company Overview: Jinrong Machinery specializes in providing comprehensive beverage machinery solutions, including filling, packaging, and processing equipment. They focus on quality and innovation to ensure efficient production for various beverage types.

Established: Not specified

Location: Zhangjiagang, Jiangsu Province, China

Scale: Significant operations with a strong reputation in the beverage machinery sector.

Main Products: Canning machines, filling machines, packaging machines, and processing equipment.

Export Data: Exports widely to international markets, emphasizing quality control and after-sales service.

Website: jinrongmachinery.com

Tips When Choosing a Can Sealing Machine

When selecting a can sealing machine, food brands should keep in mind several important factors:

Sealing Effectiveness: It’s crucial for the machine to provide excellent airtightness, ensuring that air and moisture do not affect the food’s freshness.

Compatible Materials: Various sealing machines are designed to work with different materials, such as paper cans, metal cans, and glass jars.

Efficiency: The degree of automation and the production speed of the machine have a direct impact on output and cost-effectiveness.

Flexibility and Adaptability: The machine should be adjustable to fit different can sizes, based on the brand’s packaging requirements.

Price and After-Sales Service: The machine’s price and the quality of the supplier’s after-sales service are essential considerations when making a purchasing decision.

Two Recommended Sealing Machines for Small Business

To better meet the diverse needs of food brands, we recommend the following two highly efficient can sealing machines:

Small Table Can Sealing Machine

1. seal diameter: from 45-100mm

2. seal height: from 30-180mm

3. can seal composite can, tin can, bottle can etc

4. can seal about 1000pcs per hour

5. cost: about $480-$ 500

Floor-Standing Sealing Machine

1. seal diameter: from 35-180mm (custom)

2. seal height: from 25-200mm(custom)

3. can seal composite can, tin can, bottle can etc

4. can seal about 1200pcs per hour

5. cost: about $1400 - $1600

Composite Cans: The Ideal Sealed Packaging Solution for Food

Composite cans are a great choice for food packaging as they address various requirements such as effective sealing, sustainability, and cost-effectiveness. These cans provide strong sealing without the need for plastic bags. With the help of specialized sealing machines, food can be directly inserted into the can and sealed, which helps maintain freshness over time while avoiding plastic waste. Additionally, all the materials used in composite cans are recyclable, making them an eco-friendly and efficient option.

All Paper Tube Co.: Custom Cardboard Food Containers and One-Stop Sealing Solutions

All Paper Tube Co. provides professional cardboard food containers customisation services. We not only supply high-quality paper tube packaging but also offer a one-stop solution for purchasing sealing machines. Whether for small-batch production or large orders, we deliver cost-effective solutions with quick turnaround times to meet your needs.