Ever picked up a product and immediately thought “wow, this feels expensive”? Chances are, you were holding something with foil stamping. It’s that shiny, metallic finish that makes ordinary packaging look like it belongs in a luxury boutique.

But here’s the thing – most people have no clue what foil stamping actually is or how it works. They just know it looks good and feels premium.

So, What is Foil Stamping Exactly?

Think of foil stamping as putting makeup on your packaging, but way more permanent and sophisticated. It’s a printing technique where you use heat, pressure, and specially made metal stamps to stick thin metallic film onto paper, cardboard, or other materials.

The cool part? What is foil stamped onto your packaging doesn’t fade, scratch off easily, or look cheap like some printed “metallic” inks do. We’re talking about actual metallic film that gets permanently bonded to your material.

I’ve seen companies transform their entire brand perception just by adding a simple gold foil stamp to their logo. Suddenly, customers think they’re buying something premium.

Source: Brand Enhancement Case Studies

For a behind-the-scenes look at how foil stamping transforms brands from an industry insider’s perspective, check out my Medium article: “The Art of Foil Stamping: How a 19th Century Technique Became Modern Packaging’s Secret Weapon”

The Magic Behind Foil Stamping Printing

Here’s where it gets interesting. The foil itself isn’t just one layer – it’s actually several super-thin layers stacked together, kind of like a high-tech sandwich.

You’ve got the carrier layer (think of it as the delivery truck), the release layer (which lets the foil separate cleanly), the color layer (where all the visual magic happens), and finally the adhesive layer that makes everything stick permanently when heated.

Source: External materials science research

When someone asks “what is foil stamping in printing,” this multi-layer system is what separates it from regular printing. Traditional ink just sits on top of your material. Foil actually bonds with it at a molecular level.

Why Heat Makes All the Difference

Hot foil stamping works because of something called thermal activation. Basically, when you heat that adhesive layer to just the right temperature (usually somewhere between 200-400°F), it turns into superglue for a split second. That’s when the magic happens – the foil becomes one with your packaging material.

Different Ways to Do Foil Finishing

Not all foil stamping is created equal. There are actually several techniques, and choosing the right one can make or break your project.

The Basic Flat Method

This is your bread-and-butter foil stamping. A heated metal die (usually made from brass or copper) presses the stamping foil onto a flat surface. It’s cost-effective and works great for logos, text, and simple designs. Most small businesses start here because it gives you that premium look without breaking the bank.

Getting Fancy with Sculptured Effects

Want to really impress people? Sculptured foil stamping combines embossing with foil application. You’re not just adding color – you’re creating raised, three-dimensional effects that people can actually feel. It’s like turning your packaging into a piece of art.

Source: Premium Finishing Options

Special Applications for Round Surfaces

Here’s something cool – peripheral foil stamping can wrap around cylindrical objects like paper tubes. This technique is perfect for products like lip balm tubes, document holders, or specialty food containers. The foil goes all the way around the circumference, creating a seamless premium look.

Souce: Cylindrical Packaging Solutions

Understanding What is Foil and Your Options

When people ask “what is foil” in the context of stamping, they’re usually surprised by how many options exist. It’s not just gold and silver anymore (though those are still the most popular).

The Classic Metallics

Gold foil stamp applications never go out of style. There’s something about gold that screams “luxury” to our brains. Silver gives you that modern, high-tech vibe. But you can also get copper, bronze, or even colored metallics like blue, red, or green.

Going Beyond Shiny

Matte foils are having a moment right now. They give you intense color without the mirror-like shine. Then you’ve got holographic foils that create rainbow effects (great for security features too), and specialty textured foils that can make your packaging feel like leather, wood, or even fabric.

The Weird and Wonderful

Some of the coolest projects I’ve seen use specialty effect foils. Imagine packaging that changes color when you tilt it, or foil that feels exactly like snakeskin. These materials exist, and they’re becoming more affordable every year.

How Hot Foil Stamping Actually Works

Let me walk you through what happens during the actual stamping process, because it’s pretty fascinating.

Making the Dies

Everything starts with creating a custom metal die. This is basically a stamp with your design carved into it. The die material (brass, copper, or magnesium) depends on how many pieces you’re making and how detailed your design is. A good die can last for hundreds of thousands of impressions

Getting the Settings Right

This is where experience really matters. The temperature has to be just right – too cool and the foil won’t stick, too hot and you’ll burn your material or get uneven coverage. The pressure and timing are equally critical. It’s more art than science, honestly [

Quality Control That Actually Matters

Good foil finishing operations check every batch for adhesion strength, color consistency, and registration accuracy. They’re looking for things the average person might not notice but that separate professional work from amateur attempts.

Why Paper Tubes Are Perfect for Foil Stamping

As someone who works with custom paper tube packaging every day, I can tell you that tubes are ideal for foil applications. Here’s why.

Surface Characteristics

Paper tubes have smooth, consistent surfaces that accept foil beautifully. Unlike corrugated cardboard or textured papers, tubes give you crisp, clean foil transfer every time. The cylindrical shape also adds visual interest – light hits the foil from different angles as people handle the tube.

Industry Applications

The cosmetics industry figured this out years ago. Walk into any high-end beauty store and you’ll see foil stamped paper tubes everywhere – lip balm containers, mascara tubes, serum applicators. The food industry is catching on too, especially for gourmet products and artisanal goods.

Branding Opportunities

A foil stamped logo on a paper tube creates instant brand recognition. Customers remember that tactile experience. It’s the difference between “nice product” and “I need to find out what brand this is”

Design Tips That Actually Work

Want to avoid the rookie mistakes that can ruin a foil stamping project? Here’s what you need to know.

Keep It Simple, Keep It Bold

Thin lines and tiny details are foil stamping’s worst enemy. The process works best with bold, simple designs that have plenty of space between elements. Think logos, not fine art. Your designer might love those delicate flourishes, but they probably won’t transfer well.

Choose Your Materials Wisely

Not all papers are created equal when it comes to foil stamping. Smooth, dense materials work best. Heavily textured or very porous materials can cause uneven transfer or poor adhesion. When in doubt, ask for samples.

Color Coordination Matters

Your foil choice should complement, not compete with, your overall design. A gold foil stamp might look amazing on deep blue packaging but terrible on bright yellow. Think about the whole picture, not just the foil element .

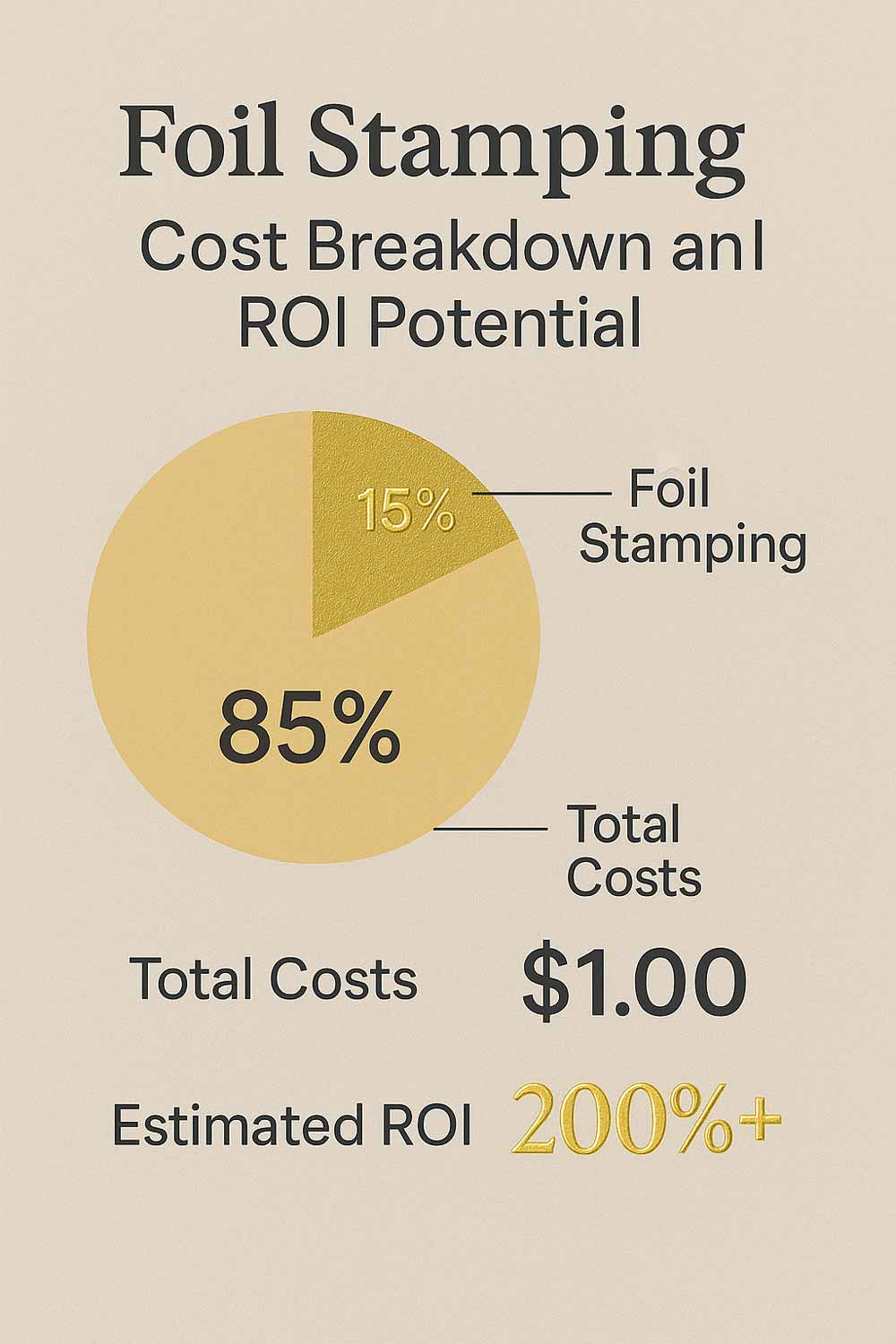

The Money Side of Things

Let’s talk about what foil stamping actually costs and whether it’s worth it.

Upfront Investment

The biggest cost is usually the custom die, which can range from a few hundred to several thousand dollars depending on size and complexity. But here’s the thing – that die will handle thousands of impressions, so the per-unit cost drops quickly with volume.

Return on Investment

I’ve seen brands increase their perceived value by 50% or more just by adding strategic foil elements. A product that used to sell for $10 suddenly commands $15-20 because it feels premium. The material cost increase? Usually under 5%.

Environmental Considerations

Everyone’s thinking about sustainability these days, and foil stamping has had to adapt.

Eco-Friendly Options

Modern foils include water-based and solvent-free options that reduce environmental impact. These work especially well with recyclable paper tube packaging, creating a comprehensive sustainability approach.

Source: Sustainable Packaging Solutions

Recycling Reality

Good news – properly applied foil stamping doesn’t interfere with standard paper recycling processes. The foil separates cleanly during the recycling process, so your beautiful packaging can still be environmentally responsible [BACKLINK: Link to external recycling industry guidelines].

Quality Control That Makes the Difference

Professional foil stamping isn’t just about having the right equipment – it’s about maintaining standards throughout production.

Testing for Durability

Quality operations test foil adhesion under various conditions. They’ll simulate handling, temperature changes, and even humidity exposure to make sure your foil won’t peel off in the customer’s hands.

Consistency Across Runs

Color matching between production runs requires careful attention to detail. Good foil stamping shops maintain detailed records of temperature, pressure, and timing settings to ensure your reorders look identical to your initial run.

What’s Coming Next

The foil stamping industry keeps evolving, and some of the new developments are pretty exciting.

Digital Integration

New hybrid technologies combine digital printing with foil stamping, opening up possibilities for variable data applications and personalized packaging. Imagine custom foil stamping for individual customers – it’s not science fiction anymore .

Advanced Materials

Researchers are developing foils with enhanced durability, broader color ranges, and improved environmental profiles. Some experimental foils can even change appearance based on temperature or viewing angle .

Choosing Your Foil Stamping Partner

Not all foil stamping services are created equal. Here’s what to look for.

Experience and Expertise

Look for a provider who can show you samples of work similar to what you want. Ask about their experience with your specific substrate and application. The learning curve for quality foil stamping is steep, and you don’t want to be someone’s practice project.

Equipment and Capabilities

Modern foil stamping requires specialized equipment. Your provider should have machinery capable of handling your substrate size and thickness, with precise temperature and pressure controls.

Making the Decision

So, is foil stamping right for your packaging? Here are some questions to consider.

Do you want to position your product as premium? Are you competing in a crowded market where you need to stand out? Do your customers value tactile experiences and visual appeal? If you answered yes to any of these, foil stamping might be exactly what you need.

The technique works across industries – from cosmetics to food packaging, from corporate materials to wedding invitations. The key is understanding your audience and choosing the right application for maximum impact.

Wrapping It Up

Foil stamping transforms ordinary packaging into something memorable. It’s not just about looking expensive – it’s about creating an experience that customers remember and associate with quality.

As a custom paper tube packaging manufacturer, we’ve seen firsthand how the right foil stamping application can completely change how customers perceive a product. The investment pays for itself through increased perceived value, better brand recognition, and higher customer satisfaction.

Whether you’re launching a new product line or refreshing an existing brand, foil stamping offers possibilities that traditional printing simply can’t match. The combination of visual impact, tactile appeal, and perceived luxury makes it one of the most effective packaging enhancements available.

The technique that started in the 19th century continues to evolve, but its fundamental appeal remains unchanged – people are drawn to things that catch the light, feel premium to the touch, and suggest quality beyond their apparent cost.

About All Paper Tube: We specialize in custom paper tube packaging with premium finishing options including professional foil stamping services. Our global manufacturing capabilities and decades of experience ensure exceptional quality for clients worldwide. Visit All Paper Tube Co. to explore our complete range of packaging solutions and foil stamping capabilities.