Many brands discover the importance of paper tube printing choices only after experiencing disappointing results – when colors appear muted, fine details get lost, or special finishes fail to adhere properly. The truth is: your paper tube material selection fundamentally determines your printing success. This comprehensive guide reveals how to navigate the complex landscape of coated, uncoated, and specialty papers to achieve stunning paper tube printing results that align with your brand vision and technical requirements.

Understanding Paper Tube Printing Fundamentals

The science behind paper tube printing begins with surface characteristics. Coated papers feature a smooth clay-based layer that seals the paper fibers, creating an ideal printing surface. Uncoated papers retain their natural porous texture, which absorbs ink differently. Specialty papers introduce unique textures that require specialized printing approaches. Each paper tube material interacts distinctly with inks and finishes, making material selection the first and most crucial decision in your paper tube printing process.

Coated Papers: The Premium Choice for Vibrant Printing

Coated paper tube material delivers exceptional results across all printing parameters. The sealed surface prevents ink absorption, allowing colors to maintain their original intensity and sharpness. This makes coated papers perfect for brands requiring:

Photographic-quality imagery with subtle gradients

Precise color matching and vibrant color reproduction

Complex foil stamping and embossing effects

UV spot gloss and other specialty finishes

Industry testing confirms that coated paper tube material achieves up to 98% color accuracy compared to digital design files. The non-porous surface also supports intricate foil stamping with 95% adhesion rates, significantly higher than uncoated alternatives. However, brands should note that the plastic-containing coatings complicate recycling processes, an important consideration for sustainability-focused projects.

Uncoated Papers: Mastering the Art of Natural Printing

Uncoated paper tube material presents both distinctive aesthetic appeal and technical challenges that require strategic approaches:

Natural kraft paper tube material demands specialized printing techniques. The dark background alters color perception, typically requiring a white underbase layer before color application. UV printing systems prove most effective, with instant-curing inks preventing absorption and maintaining color integrity. Without this underbase, colors appear muted and distorted, with industry measurements showing 40-50% color distortion compared to original designs.

Black kraft paper tube material performs poorly with conventional printing but excels with alternative finishes. The dark surface makes colored inks virtually invisible, but creates stunning contrast with metallic foils and embossing. Brands achieve best results by reserving black kraft for foil stamping applications, where the combination delivers premium visual impact.

Bleached kraft paper tube material offers a balanced approach, accepting direct printing while maintaining natural characteristics. The porous surface absorbs more ink, resulting in softer color reproduction with approximately 20% reduced saturation compared to coated stocks. This creates the distinctive vintage aesthetic many brands desire, though designers must compensate for the color shift during file preparation.

Specialty Papers: Strategic Approaches for Textured Surfaces

Specialty paper tube material requires careful consideration of texture density and printing compatibility:

Heavily textured varieties like linen or embossed patterns present significant challenges for detailed printing. The uneven surface prevents consistent ink transfer, with industry tests showing up to 30% ink coverage variation across textured areas. These materials achieve optimal results with foil stamping and embossing that enhance rather than fight the existing texture.

Fine-textured specialty papers can successfully accommodate printing when approached strategically. Solid color applications and bold graphics work effectively, while detailed imagery and subtle gradients typically reproduce poorly. The key lies in designing with the texture as an integrated element, using the natural character of the paper tube material to enhance the overall aesthetic.

Implementation Framework: Selecting Your Perfect Paper Match

Choosing the right paper tube material requires balancing multiple factors through a structured decision process:

For maximum color impact and design complexity, coated paper tube material delivers superior performance across all metrics. The non-porous surface ensures color fidelity while supporting intricate finishing techniques without technical compromise.

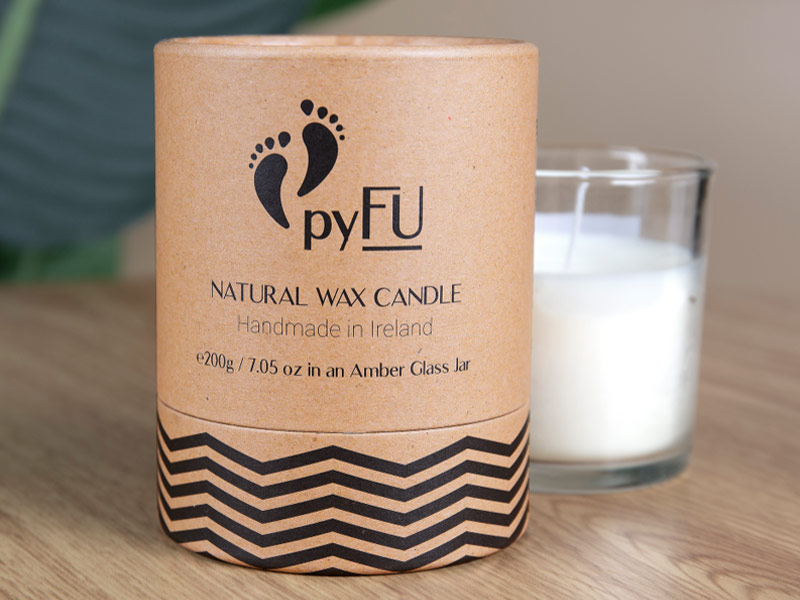

Projects emphasizing natural aesthetics typically benefit from uncoated options, though each subtype demands specific approaches. Natural kraft requires UV printing with white underbasing, bleached kraft works for softer color reproduction, and black kraft excels with foil applications.

When textural distinction takes priority, specialty paper tube material offers unique opportunities. Heavily textured varieties work best with foil and embossing, while finer-textured options can accommodate complementary printed elements.

Expert Implementation: Allpapertube’s Printing Expertise

At Allpapertube, we’ve transformed paper tube printing through scientific material analysis and production optimization. Our comprehensive paper tube material library contains over 80 validated options, each with documented performance characteristics across different printing techniques.

We recently helped a luxury cosmetics brand navigate a challenging transition from coated to recycled uncoated paper tube material while maintaining brand standards. Through controlled production trials, we developed a specialized UV printing process that achieved 90% color accuracy on the challenging substrate – a significant improvement over industry standards for similar materials.

Another client in the organic food sector needed to maintain their sustainable positioning while improving shelf impact. We implemented a strategic combination of natural kraft paper tube material with metallic foil accents, creating distinctive packaging that increased retail sales by 18% while maintaining their environmental credentials.

Our technical team maintains ongoing research into emerging paper tube printing technologies, including recent breakthroughs in water-based coatings that improve printability on recycled papers. This commitment to innovation ensures our clients access the latest advancements without sacrificing visual appeal or performance.

Conclusion: Strategic Printing for Optimal Results

Successful paper tube printing begins with recognizing that your material choice forms the foundation of all design possibilities. The specific characteristics of your selected paper tube material – whether coated, uncoated, or specialty – establish both the opportunities and limitations for color reproduction, finishing techniques, and brand communication.

By approaching paper tube printing with thorough understanding of how different papers interact with inks and finishes, brands can make informed decisions that align production outcomes with design vision. This material-first methodology transforms potential constraints into creative opportunities, ensuring final products accurately reflect brand values while accommodating practical manufacturing considerations.

The most effective paper tube printing emerges from partnerships that integrate design vision with technical expertise. At Allpapertube, we’ve built our practice around this principle, serving as both production partner and strategic advisor to brands seeking to maximize impact through informed paper tube material selection and execution.