If you ever visit a commercial print shop, you’ll see something amazing — really large machines that operate with jaw-dropping precision to move so many little pieces of paper that thousands of them are printed every single hour. This is the offset printing process at work, and it has been the heart of professional printing for decades.

But here’s what people often miss: the offset printing method isn’t just for large machines and massive runs. It is, in fact, a craft that involves chemistry, physics and artistry and, in fact, produces some of the most gorgeous stuff you read every day. From the cereal box on your breakfast table to the glossy magazine you thumb through, odds are it rolled off an offset press.

Getting familiar with the process of offset printing can save your business serious money and headaches. Too many companies jump into printing projects without understanding what makes offset printing techniques tick – and they often end up disappointed with results or shocked by costs.

Why the Offset Printing Process Works So Well

Here’s something interesting about the offset printing technique – it never actually touches the paper directly with ink. Sounds backwards, right? But this indirect approach is exactly what makes it brilliant.

Picture this: ink flows from a plate to a rubber blanket, then from that blanket onto your paper. This extra step might seem unnecessary, but it’s pure genius. The rubber blanket acts like a cushion, ensuring every fiber of paper gets perfect ink coverage without damaging delicate surfaces.

This clever offset print process delivers benefits that other printing methods simply can’t match:

- Your prints come out incredibly sharp and consistent, even on textured papers

- Large print runs become surprisingly affordable once you hit the sweet spot

- Different paper weights and types? No problem – offset handles them beautifully

- Colors stay true and registration stays tight across thousands of copies

- Printing plates last longer because they never touch abrasive paper surfaces

Manufacturing companies have discovered that offset printing techniques work exceptionally well for packaging applications. The process handles everything from lightweight labels to heavy corrugated materials with equal precision.

Source : Printing Tips for Custom Paper Tube Packaging: How to Make Your Packaging Stand Out?

Breaking Down the Offset Printing Process Step by Step

Getting Your Files Print-Ready

Before any offset printing process begins, someone needs to prepare your artwork properly. This isn’t just about making files look good on screen – it’s about translating digital designs into something physical presses can reproduce accurately.

Smart designers know these preparation tricks:

- Converting RGB screen colors to CMYK print colors (trust us, this matters more than you think)

- Bumping resolution up to 300 DPI or higher for crisp details

- Adding bleeds so colors extend beyond cut lines

- Double-checking that fonts won’t cause problems during printing

- Setting up color profiles that match your chosen printing facility

Skip any of these steps, and you might discover problems only after spending money on press time. Better to get it right upfront.

Creating the Printing Plates

The offset printing method depends entirely on precisely made printing plates. Modern facilities use Computer-to-Plate technology that’s pretty remarkable – lasers literally burn your image onto aluminum plates with microscopic accuracy.

Here’s what happens during plate creation:

- Laser systems etch image areas onto specially coated aluminum

- Chemical baths develop the plates, creating areas that attract ink and others that repel it

- Quality technicians inspect every plate under magnification

- Plates get stored in controlled environments until press time

Each color in your job needs its own plate. Four-color printing means four separate plates, each handling cyan, magenta, yellow, or black portions of your image.

Setting Up the Press

Press operators are skilled craftspeople who turn mechanical equipment into precision instruments. This phase of the process of offset printing determines whether your job turns out beautifully or becomes expensive waste paper.

Operators handle numerous setup tasks:

- Mounting plates onto rotating cylinders with perfect alignment

- Balancing ink and water systems (getting this wrong ruins everything)

- Adjusting registration so colors line up exactly

- Loading the right paper stock for your specific job

- Running test sheets and making fine adjustments until everything’s perfect

Different Offset Printing Techniques for Different Needs

The Standard Four-Color Method

Most commercial printing uses the CMYK offset printing technique – those four colors we mentioned earlier. This offset print process can reproduce almost any color by layering tiny dots in different patterns and densities.

What makes CMYK so popular:

- Covers the vast majority of colors people want to print

- Uses standardized inks that behave predictably

- Keeps costs reasonable for full-color work

- Works with established color management systems

When You Need Exact Brand Colors

Sometimes CMYK just won’t cut it. Maybe your company logo uses a specific shade that CMYK can’t match perfectly. That’s where spot color offset printing techniques become valuable.

Spot colors use specially mixed inks rather than combining standard colors. This offset printing method ensures your brand colors look identical every single time, whether you’re printing business cards or billboard posters.

Benefits of spot color printing:

- Perfect brand color matching every time

- Special effects like metallic or fluorescent inks

- Consistent results across different print runs

- Enhanced visual impact for important design elements

Source: custom packaging solutions that utilize spot color printing

Getting Fancy with Special Effects

Advanced offset printing processes can add impressive finishing touches that make printed pieces stand out. These specialized offset printing techniques create textures, shine, and depth that catch attention immediately.

Popular special effects include:

- Spot varnish that adds shine to specific areas

- Embossing that creates raised text or images

- Foil stamping for metallic accents

Multiple varnish layers for unique textures

Keeping Quality High Throughout the Offset Printing Process

Watching Everything in Real Time

Modern offset printing methods use sophisticated sensors and cameras that monitor print quality continuously. These systems catch problems before they waste material or compromise your job.

Advanced monitoring catches:

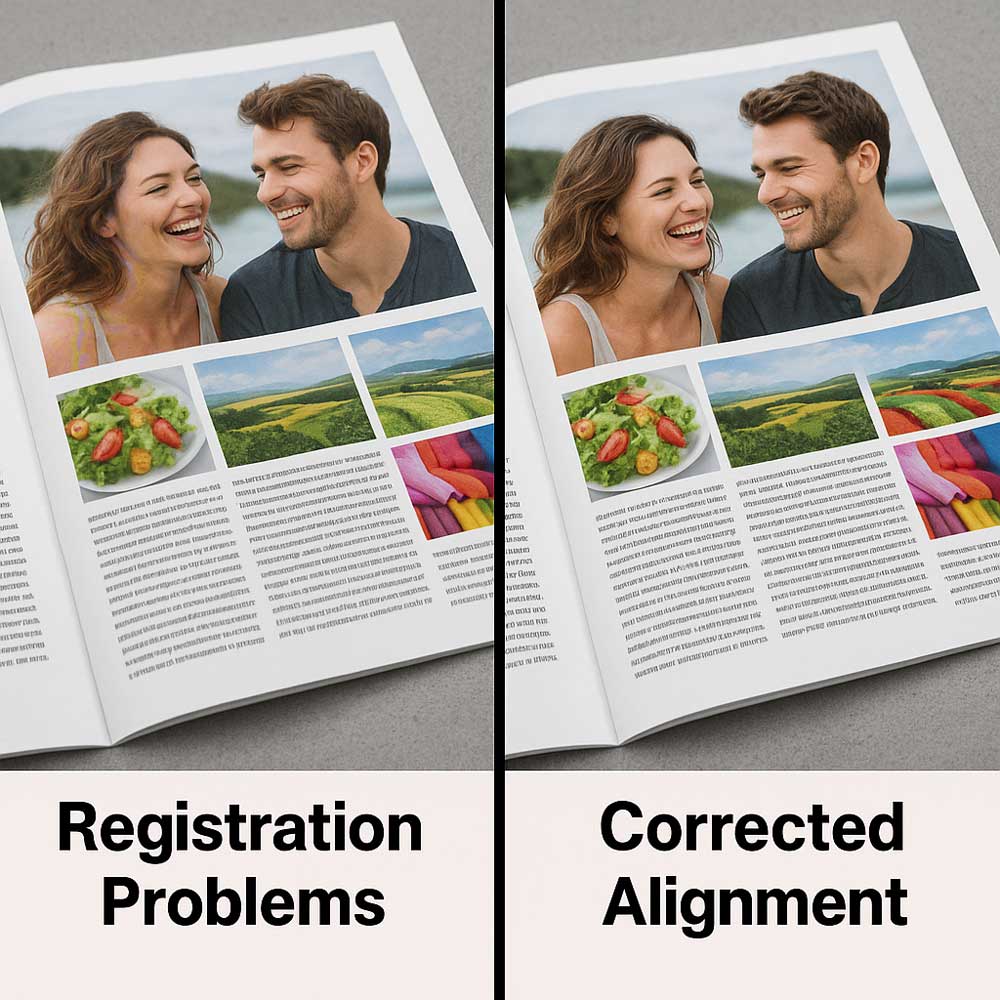

- Color shifts that happen gradually during long runs

- Registration problems that throw colors out of alignment

- Surface defects like streaks or spots

- Density variations that affect image quality

Final Inspection Before Delivery

The last step of any offset print process involves human eyes and experience. Trained inspectors examine finished pieces against your original specifications and approved samples.

Inspection covers these crucial areas:

- Color accuracy compared to approved standards

- Print registration across all colors

- Surface quality and consistency

- Dimensional accuracy for folding or assembly

- Overall appearance and finishing quality

Two Main Types of Offset Printing Processes

Web Offset for High-Speed Production

Web offset offset printing processes feed continuous paper rolls through presses at incredible speeds. This offset printing method excels when you need thousands or millions of identical pieces quickly.

Web offset shines for:

- Newspapers that need fast turnaround

- Magazines with large circulations

- Direct mail campaigns

- Packaging that requires high volumes

Sheet-Fed Offset for Premium Quality

Sheet-fed offset printing techniques handle individual paper sheets, allowing for tighter quality control and more flexibility. This process of offset printing works best when print quality matters more than raw speed.

Choose sheet-fed offset for:

- Marketing materials that represent your brand

- Packaging that needs perfect color matching

- Short to medium print runs

- Projects requiring special papers or finishes

Making Smart Choices About Materials and Inks

Picking the Right Paper

Successful offset printing processes start with choosing appropriate substrates for your specific needs. Different papers behave differently under printing conditions, and smart choices prevent problems later.

Consider these paper factors:

- Surface smoothness affects how sharply details print

- Absorbency determines how inks dry and look

- Weight and thickness impact folding and handling

- Coating types change color appearance and feel

Understanding Ink Behavior

Professional offset printing techniques rely on inks formulated for specific applications and conditions. Understanding how inks behave helps predict results and avoid disappointments.

Important ink characteristics:

- Viscosity affects how smoothly inks transfer and spread

- Drying speed determines production scheduling

- Color strength impacts how vibrant prints appear

- Environmental factors like temperature affect consistency

Solving Common Offset Printing Process Problems

When Colors Won’t Stay Consistent

Color consistency challenges plague many offset printing processes, but experienced operators know how to identify and fix these issues quickly. Understanding root causes helps prevent problems before they start.

Common culprits behind color problems:

- Ink and water balance shifts during long runs

- Temperature changes in the printing environment

- Paper characteristics that vary between batches

- Press speed adjustments that affect ink transfer

- Plate conditioning that changes over time

Registration Headaches

Perfect registration makes multi-color offset printing techniques look professional and polished. When registration goes wrong, projects can become expensive disasters that need reprinting.

Factors affecting registration accuracy:

- Mechanical adjustments on aging equipment

- Environmental conditions that affect paper stability

- Substrate expansion or contraction during printing

- Operator experience and attention to detail

- Regular maintenance schedules and equipment condition

What’s Coming Next for Offset Printing Methods

Digital Technology Integration

Today’s offset printing processes increasingly blend traditional methods with digital innovations. These hybrid approaches combine offset’s quality advantages with digital precision and automation.

Emerging digital integration includes:

- Robotic plate changing systems that reduce setup time

- Automated color management that maintains consistency

- Predictive maintenance that prevents unexpected breakdowns

- Data analytics that optimize production efficiency

- Remote monitoring capabilities for real-time oversight

Environmental Improvements

Sustainability concerns drive innovation in offset printing techniques, pushing the industry toward reduced environmental impact while maintaining quality standards.

Green printing initiatives include:

- Plant-based ink formulations that reduce petroleum use

- Chemical reduction programs that minimize waste

- Energy-efficient press designs that cut power consumption

- Waste reduction strategies that maximize material usage

- Comprehensive recycling programs for all consumables

Choosing the Right Offset Printing Process for Your Project

Making Sense of Volume and Budget

Different offset printing methods make financial sense at different volume levels. Understanding these economics helps you choose the most cost-effective approach for specific projects.

Key volume considerations:

- Setup costs get spread across more pieces in larger runs

- Break-even points vary significantly between different printing methods

- Rush jobs often cost more regardless of volume

- Quality requirements might justify premium approaches

- Future reprinting needs affect initial method selection

Matching Methods to Applications

Various offset printing techniques excel in specific applications. Smart project planning matches the process of offset printing to end-use requirements for optimal results.

Application-specific factors:

- Durability needs for outdoor or high-handling applications

- Environmental conditions that printed pieces will face

- Distribution and shipping requirements

- Regulatory compliance for food packaging or medical applications

- Brand presentation standards that affect quality expectations

The Bottom Line on Offset Printing

The offset printing process remains relevant because it delivers something many businesses need: consistent, high-quality results at reasonable costs for medium to large quantities. While digital printing grabs headlines with customization capabilities, offset printing techniques still dominate commercial production for good reasons.

Knowing how this offset print process functions will make you better decisions with print projects. Whether you’re designing the packaging for a new product, or marketing collateral for a major promotion, or any other kind of company printing, being aware of the positive and negative points associated with the different offset printing methods can save you from making costly mistakes.

There are a lot of changes happening in the printing world but the basic idea behind the offset printing process is strong. Companies that take time to understand these offset printing techniques position themselves to get better results while controlling costs effectively.

Smart businesses build relationships with printing partners who can explain options clearly and recommend the best approaches for specific projects. When you find printers who combine technical expertise with honest guidance, you’ve discovered partners who can help your business succeed.