In the competitive world of e-commerce and DTC branding, packaging is more than just a container—it’s a branded experience. But as customer expectations rise, so do mailer box costs, especially when factoring in materials, shipping, and storage. This guide breaks down why mailer box costs add up and shows you how to cut them smartly—without cutting corners.

Why Mailer Box Costs Add Up

Before diving into solutions, it is important to understand what contributes to mailer box costs. Typically, mailer box costs break down into several key components:

| Cost Component | Description | % of Total Mailer Box Costs |

|---|---|---|

| Material | Paperboard quality and weight (Kraft, C2S, etc.) | 35–45% |

| Printing | Color printing, coatings, and finishes | 15–25% |

| Shipping | Based on volumetric weight and distance | 15–20% |

| Storage | Warehousing and handling fees | 10–15% |

| Setup & Labor | Die-line preparation, tooling, and production | 5–10% |

According to Packhelp, premium mailer boxe costs can range between $1.80 to $3.50 per unit for small volumes—costs that quickly scale for growing brands.

🥇 Top Strategy: Combo Orders (Paper Tubes + Mailer Boxes)

If your product requires both primary and secondary packaging, combining orders—such as pairing paper tubes for product housing and mailer boxes for shipping—is a powerful strategy to reduce overall mailer box costs.

✅ Better Negotiation Power for Lower Mailer Box Costs

When you place a combined order for both paper tubes and mailer boxes, you automatically increase your order volume, which:

-

Enhances bargaining power for bulk discounts

-

May qualify for shared die-line or printing setups

-

Reduces minimum order quantity (MOQ) thresholds

-

Speeds up sample approval and production timelines

Case Example: A U.S.-based candle brand saved over 18% in total packaging cost by ordering both tube and mailer packaging from All Paper Tube Co. in a single project.

✅ Lower Freight & Storage Costs

By ordering two packaging types together:

-

Freight can be consolidated, lowering the number of shipments

-

Packaging can be optimized for container space

-

Inbound storage and warehouse handling becomes easier and more predictable

Coordinating the dimensions of your canister and mailer box to fit perfectly can dramatically reduce unused volume and shipping inefficiency.

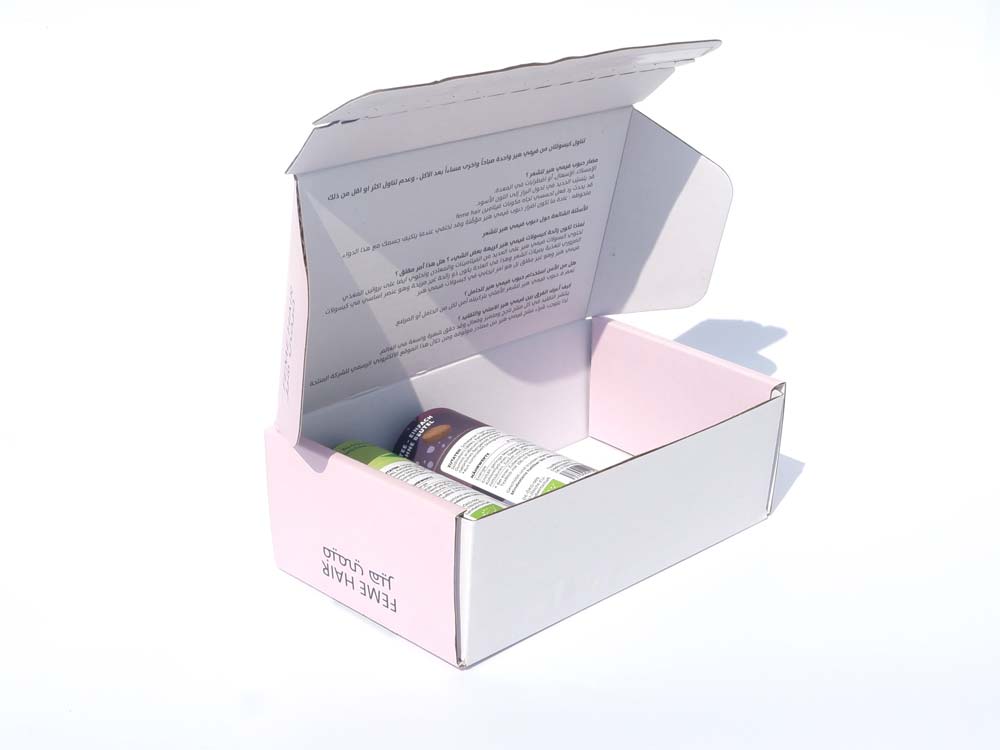

✅ Stronger Brand Cohesion

Consumers love an unboxing experience that tells a story. A consistent theme between your product tube and shipping mailer box helps:

-

Reinforce brand identity through matching graphics and tone

-

Improve Instagrammability and organic shares

-

Elevate the perceived value of your product, without adding to mailer box costs.

This strategy is especially effective in beauty, fashion, food, and gift industries.

✅ What All Paper Tube Co. Offers

We specialize in both paper tubes and foldable mailer boxes, meaning:

-

One vendor, one communication chain

-

Consistent print quality and color accuracy across formats

-

Optimized layouts for nested or compact shipping

-

Streamlined sample delivery and production scheduling

This approach not only enhances branding—it’s the smartest way to lower your mailer box costs long-term.

Other Proven Cost-Reduction Strategies

1. Lightweighting (Reduce Paperboard GSM)

Using thinner yet structurally sound materials is an easy way to trim cost:

-

For instance, switching from 250gsm to 200gsm Kraft paperboard can save up to 15% on material costs.

-

Double-wall or B-flute board can still maintain protective strength for heavy items.

Tip: Always request strength testing when reducing GSM to avoid compromising product safety.

2. Order in Bulk, Smartly

Larger orders almost always reduce unit price, but that doesn’t mean you need to overstock.

-

Negotiate tiered pricing: “What if I order 3,000 units now and another 2,000 within 3 months?”

-

Align packaging orders with promotional cycles or new launches.

3. Use On-Demand Print Services

If you’re an early-stage brand or frequently rotate designs:

-

Consider platforms like Packlane or EcoEnclose, which offer low-MOQ digital printing on eco-friendly substrates.

-

This avoids the high upfront tooling and minimums of offset printing.

Digital printing now rivals offset in quality and allows for quick A/B testing of packaging styles.

4. Standardize Box Sizes

Following the lead of brands like Warby Parker, which standardized their mailer box sizes, can help you:

-

Save up to 20% on logistics by optimizing storage and shipping pallet loads.

-

Eliminate retooling costs across SKUs.

Stick with 1–3 box templates and build internal design guides to streamline the process.

Final Thoughts

Cutting mailer box costs doesn’t mean going cheap—it means going smart. Whether it’s combining canister and mailer box orders, lightweighting materials, or simplifying SKU dimensions, the key is to work with a flexible packaging partner that understands your brand goals and growth path.

At All Paper Tube Co., we don’t just make boxes—we help you make packaging that works harder for your brand and budget.

Ready to explore combination packaging solutions? Contact our team and get started with custom options tailored to your products.