Launching a premium brand is a massive balancing act. You have a product you’re proud of—like Tom’s freeze-dried toddler food—but you’re also staring at the “startup paradox”: you need packaging that projects a high-end image while ensuring absolute product safety. This is where food-grade canisters become more than just a container; they become a strategic tool for growth. I’ve guided many founders through this exact transition, showing them that your packaging doesn’t have to be “final” at launch—it just needs to be smart.

1. The Reality Check: What Founders Actually Need

When you’re starting with 500 units per SKU, you’re not just buying a box; you’re buying a proof of concept. From Tom’s inquiry, we can see the three big “must-haves” in his food-grade canisters:

Premium Trust: Parents won’t buy baby food if the packaging looks flimsy. It needs that “heavy,” high-quality feel.

The Moisture Battle: Freeze-dried products turn to mush if they hit humidity. The seal isn’t just a detail; it’s the life of the product.

Tamper-Evidence: A seal that says “I’ve never been opened” is non-negotiable in the food industry.

3. My Advice to Tom (and Founders like him)

If you’re launching in May or June, my best advice is this: Don’t over-engineer the process, but never under-engineer the safety.

Focus on the Barrier: If you’re selling freeze-dried powder, moisture is your biggest risk. Whether you use an inner bag or a functional sticker seal, test it in a humid room for two weeks. If the powder stays dry, your packaging works.

Design for the “Unboxing”: Parents love the ritual. A custom paper tube feels like a gift, not just a container. Even with a simple sticker seal, the “pop” of the lid creates a brand memory.

Think in Tiers: Start with the sticker or bag method to keep your MOQs low. As your SKUs grow, we’ll help you transition into machine-sealing to bring your per-unit cost down.

2. The Evolution: Don’t Buy the Machine Before the Market

One of the biggest mistakes I see is startups buying expensive industrial sealing equipment too early. Packaging should evolve with your sales.

Stage 1: The “Smart Launch” (Manual Sealing)

Perfect for: 500 – 2,000 units

In the beginning, your goal is to get the product out the door safely. You don’t need a massive production line for this.

The Foil Bag + Tube Combo: Use a high-barrier foil bag for the food, heat-seal it manually, and tuck it into custom food-grade canisters. It’s double protection and looks incredibly high-end.

The Functional Sticker Seal: This is a game-changer for startups. Instead of a machine-crimped lid, we use a specialized, high-tack functional sticker seal that wraps over inner lip of food-grade canisters.

Why it works: It acts as a primary sealing barrier and a tamper-evident strip. It tells the customer the product is fresh and secure, but it only takes a human hand to apply. No expensive machinery required.

Stage 2: The “Scale-Up” (Semi-Auto Sealing)

Perfect for: When you’re hitting 5,000+ units

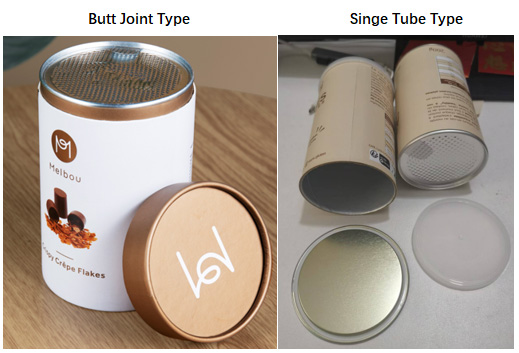

Once your product is flying off the shelves, manual stickers become a bottleneck. Now it’s time to move toward a more “industrial” look with custom food-grade canisters that uses integrated lids.

Machine-Sealed EOE (Easy-Open Ends): This is that classic “premium” feel—a metal or foil pull-tab lid.

The Setup: You don’t need a factory-sized line yet. You can start with a small semi-automatic seamer. It fits on a tabletop, costs significantly less than a full line, and gives you that 100% airtight, professional seal that extends your shelf life to 12 or 24 months.

The Next Step?

I’d love to send you a “Founder’s Sample Pack.” It includes a tube with a functional sticker seal (the manual way) and a machine-sealed EOE tube (the pro way).

You can feel the weight, test the seal, and see which one fits your current production capacity. Where should I send them?