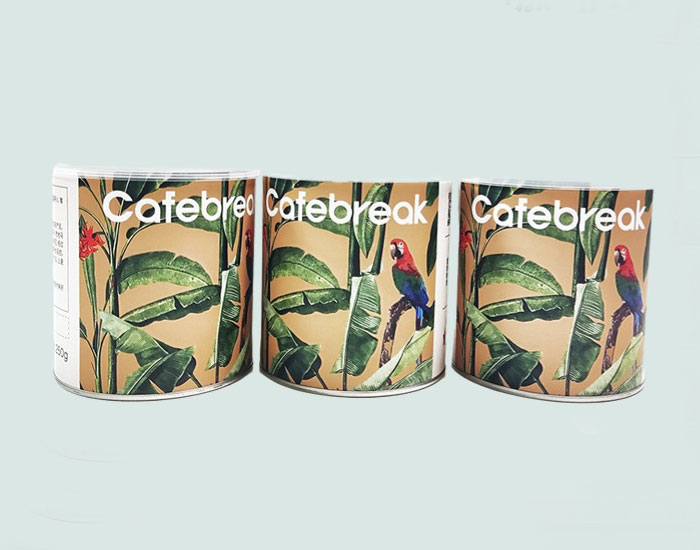

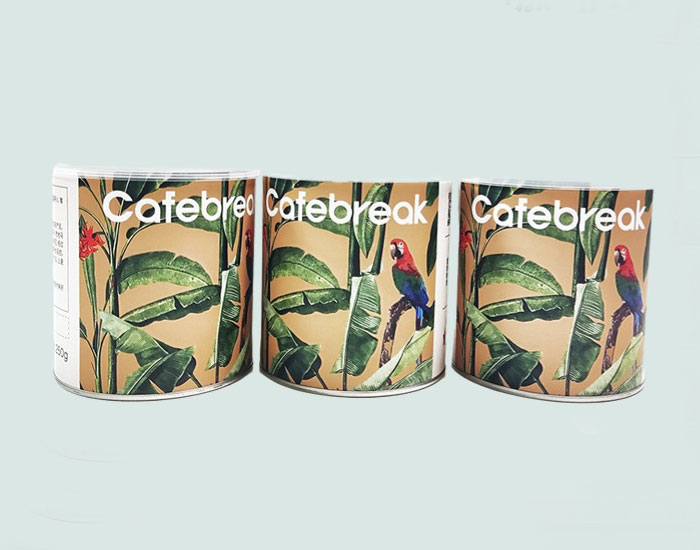

How to Blend Budget and Sustainability in Coffee Packaging: The Composite Can Solution

In the current coffee ind

Custom stickers and labels for food, beverages, daily necessities, beauty products, pharmaceuticals, and more. Clear, high-quality printing with various materials available at a low cost!

Custom semi-permanent tattoo sticker services made from safe, eco-friendly materials. Waterproof, peel-resistant, and can be applied anywhere on the body to showcase your individuality!

Custom tags and cards for clothing, pants, shoes, socks, and hats. Available in various materials and styles. Exquisite printing, high quality, and affordable prices.

Explore our versatile material pptions for custom paper tubes.

Exploring printing options for your packaging needs.

Selecting the right closure for your paper tubes ensures functionality and enhances the overall presentation of your product, offering both security and style.

2 different canning seamers for our paper tube paper canister packaging, cheap cost high efficience.

Committed to providing innovative,eco-friendly packaging solutions, custom paper tubes tailored to meet the unique needs of various industries.

We offer eco-friendly materials, flexible customization options, and high-quality printing to ensure your packaging not only protects your products but also enhances your brand's presence.

Custom paper tubes are packaging containers made of paper, using paper as the raw material. They comply with the global trend of environmentally friendly packaging, making them favored by the packaging industry. Although paper tube packaging is good, do you know how it is produced?

Don’t be fooled by the small size of a paper tube; it may seem simple, but the production process for the manufacturer is complex and cumbersome. Firstly, custom paper tubes come in various specifications. Our company’s molds alone have dozens of diameters, with heights ranging from 20mm to 600mm. Because it is a customized product, each batch is produced according to the customer’s requirements, going through all the processes to be introduced below.

Today, I will only introduce the production process of the custom paper tube.

The production process of the custom paper tube is as follows:

paper cutting – tube rolling – tube cutting – label application – assembly – cleaning – packaging.

We start with large rolls of paper. The custom paper tube requires 3-4 sheets of paper rolled together. Since different diameters require different widths of paper, the width of the cut paper varies.

This is the process of forming the paper tube using a tube rolling machine. The machine binds several cut papers together to form a paper tube. Tubes with different diameters require different widths of paper.

After rolling, the paper tube is longer than needed. It is then cut to the required height.

After tube cutting, pre-printed copperplate paper labels are manually glued onto the paper tube.

After applying labels, the paper tubes are still separate. They need to be assembled into the final cylindrical product, including the inner tube, top cap, and bottom cover. This process involves several steps as below:

1.

Inner Tube Edge Rolling: The inner tube is part of the innermost layer of the cylinder and needs to be bonded with the bottom cover. The treatment of the edges can be customized according to customer requirements. Rolling the upper edges inward serves two purposes: it complements well with the built-in iron cover (1), and it prevents the edges of the paper from cracking after multiple uses (2).

2.

Top Cover Edge Rolling and Pressing: The top cover is sealed at one end, and there are two sealing methods: rolling edge sealing (1) and flat bottom sealing (2). Rolling edge sealing is done by a machine. After rolling the edge, glue is applied, and a pressing machine is used from the inside to press the film, bonding it with the glue. Currently, flat bottom sealing can only be done manually.

3.

Bottom Cover Edge Rolling: The treatment of the bottom cover is identical to that of the top cover. According to customer requirements, the edges are processed. However, the bottom cover cannot be sealed independently. The inner tube needs to be inserted first, forming a double-layered cylinder, before sealing.

4.

Fitting the Tube: Fitting the tube involves inserting the inner tube into the bottom cover. Glue is applied to the outer part of the inner tube, and then it is inserted to prevent it from coming off.

After completing these steps, there are two major stages left:

After assembly, excess glue needs to be wiped off, and both the inner and outer tubes need to be dusted again.

Before the final packaging, the cylindrical product needs to be inspected. This involves checking for cleanliness and ensuring proper assembly without defects or mistakes. Only after inspection can the product be packaged.

By now, I believe you have gained a deep understanding of custom paper tubes manufacturing, and you are eager to use this environmentally friendly and unique packaging method to showcase your products and brand. Let us help you with that. You can contact us through the following ways to get the best packaging solution for your products using paper tubes. Come join us soon!

"Your Packaging Our Priority ! We care it for you so you don't have to."

All Paper Tube

In the current coffee ind

Packaging, presumably a s

Change Begins at the Dinn

Food safety is paramount

In the fast paced and gro

All Paper Tube Co. provides intelligent and innovative cardboard paper tube packaging solutions, from design, research, development, and production.

We hope to build a sustainable and greener future for our planet, together with you.

Copyright © 2022 Orr Industrial (Shenzhen) Co. | Sustainable Packaging Solution Provider

It is an easy step, fill out the form and we will be in touch shortly.