How to Blend Budget and Sustainability in Coffee Packaging: The Composite Can Solution

In the current coffee industry, many brands are finding […]

Custom stickers and labels for food, beverages, daily necessities, beauty products, pharmaceuticals, and more. Clear, high-quality printing with various materials available at a low cost!

Custom semi-permanent tattoo sticker services made from safe, eco-friendly materials. Waterproof, peel-resistant, and can be applied anywhere on the body to showcase your individuality!

Custom tags and cards for clothing, pants, shoes, socks, and hats. Available in various materials and styles. Exquisite printing, high quality, and affordable prices.

Explore our versatile material pptions for custom paper tubes.

Exploring printing options for your packaging needs.

Selecting the right closure for your paper tubes ensures functionality and enhances the overall presentation of your product, offering both security and style.

2 different canning seamers for our paper tube paper canister packaging, cheap cost high efficience.

Committed to providing innovative,eco-friendly packaging solutions, custom paper tubes tailored to meet the unique needs of various industries.

We offer eco-friendly materials, flexible customization options, and high-quality printing to ensure your packaging not only protects your products but also enhances your brand's presence.

Hey there, beauty enthusiasts! Let’s dive into the world of paper tube lip balm push-up packaging, an innovative and eco-friendly choice that’s taking the market by storm. Here’s everything you need to know about this awesome packaging, from its stylish looks to how it works and how it recycles!

Keep reading:

Let’s explore further.

Sleek and Cylindrical Design: our paper tube lip balm push-up packaging boasts a sleek, cylindrical shape that’s perfect for holding and carrying around. It’s simple, chic, and fits any occasion.

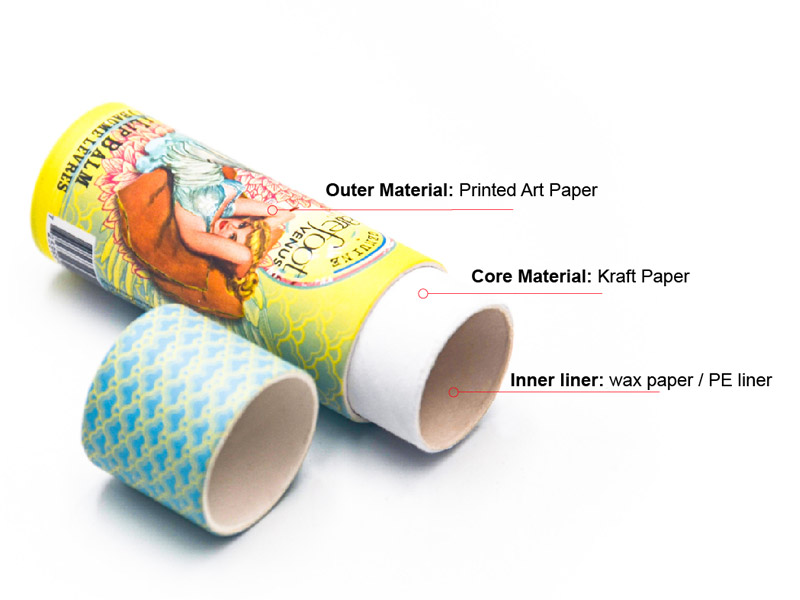

Eco-Friendly Paper Material: The outer layer is made from high-quality paper materials, customizable to suit your brand’s needs. Choose from recycled paper, kraft paper, or other sustainable options, all with a planet-friendly twist.

Custom Printing and Decoration: Get creative with various printing and decoration techniques like foil stamping, embossing, and UV printing. Show off your brand’s logo, product info, and eye-catching designs to make your packaging truly stand out.

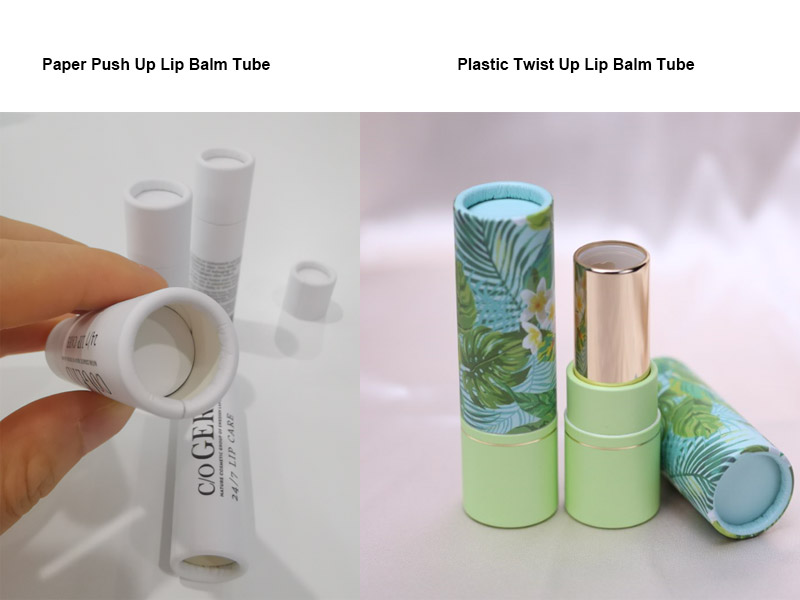

Convenient Closure: our packaging features easy-to-use closure mechanisms to keep your lip balm safe and secure when not in use. Popular options include bottom paper disc push up, bottom plastic twist up, ensuring both safety and convenience for your customers.

Eco-Friendly: Made with sustainable paper materials, our packaging aligns with modern consumers’ eco-conscious values. Paper is easy to recycle and decomposes naturally, reducing environmental impact.

Lightweight: Paper tube packaging is lightweight and portable, making it perfect for on-the-go use or travel. This added convenience makes our packaging a practical choice for busy lifestyles.

Aesthetic Appeal: With customizable designs, our paper tube lip balm push-up packaging can reflect your brand’s unique style, from minimalist elegance to luxurious opulence. Your packaging will not only protect your product but also enhance its visual appeal.

Safety First: Our non-toxic, safe-to-use paper materials meet all cosmetic packaging safety standards. This ensures that your lip balm remains uncontaminated and intact, ready for smooth application every time.

Push-Up Mechanism: The heart of our packaging is its nifty push-up mechanism. Inside, a movable base lets users push the lip balm up as needed. Simply press the bottom to raise the balm– easy peasy!

User-Friendly: Operating the push-up mechanism is a breeze. Just a gentle push on the bottom to adjust the balm’s length, making it super intuitive and hassle-free.

Sealed for Freshness: The push-up design ensures that the lip balm is fully sealed when not in use, keeping out dust and air to maintain its quality. The secure cap adds an extra layer of protection for a fresh and safe product.

With all these fantastic features, it’s clear that paper tube lip balm push-up packaging is not just trendy but also practical, safe, and environmentally responsible. It’s time to elevate your product’s market appeal while showing off your brand’s commitment to sustainability and innovation. Ready to make the switch? Let’s get started!

Creating standout paper lip balm packaging is a fantastic way to reflect your brand’s unique identity and commitment to sustainability. Here’s how you can do it:

Push-Up Tubes: These are popular and eco-friendly. Users push up the balm from the bottom disc, adding a fun, interactive element.

Twist-Up Tubes: Combining convenience with eco-friendliness, these are similar to traditional plastic tubes but made from paper outer.

Moreover, we can customize the lids and bodies of paper tube packaging in various proportions to accommodate different capacity requirements, ensuring ease of use. Brands can also incorporate personalized printing designs to enhance the visual appeal.

Below are 3 examples designed in different ratio.

Coated Paper (Copperplate Paper): Smooth and high-quality, perfect for vibrant and detailed printing. Ideal for a polished, premium look.

Kraft Paper: Rustic and eco-friendly, perfect for brands emphasizing natural and organic products.

Specialty Papers: Textured, recycled, or custom-dyed papers add a unique feel and aesthetic.

Common weights of lip balm on the market typically include the following:

We can customize the sizes and dimensions of lip balm paper tube packaging to meet these capacity requirements. While one import point we must remind you that, do care about the user experience.

User Convenience: Ensure the diameter is at least 18mm so users can easily push the balm up with their fingers. Customize the height to match your product’s volume for a compact yet sufficient design. A too small diameter like 12mm will get hard for finger to fit in.

2.4.1 Digital Printing

Digital printing offers flexibility and efficiency, making it ideal for short runs and personalized printing. Here are some ways to leverage digital printing to highlight your brand:

2.4.2 Four-Color Printing (CMYK)

Four-color printing is suitable for large-scale production and can achieve rich color effects. Here are some ways to use four-color printing to highlight your brand:

2.4.3 Hot Stamping and Foil Embossing: Adds a luxurious touch with metallic or glossy effects, making your brand logo stand out.

2.4.4 Embossing and Debossing: Adds texture and a premium feel, highlighting key brand elements.

By carefully selecting materials, structural designs, and printing techniques, you can create paper lip balm packaging that not only protects your product but also enhances your brand image and appeals to eco-conscious consumers.

Creating standout paper lip balm packaging is essential to reflect your brand’s unique identity and commitment to sustainability. Let’s use Burt’s Bees as a case study to illustrate how to effectively design and customize your packaging.

Burt’s Bees uses a push-up tube design for their paper lip balm packaging. This structure allows users to easily push the balm up from the bottom, providing a simple and intuitive user experience.

Burt’s Bees often uses kraft paper for its natural and organic look, aligning with the brand’s emphasis on natural ingredients and sustainability.

Burt’s Bees lip balms provide 2 capacities to choose from, 0.13oz and 0.34oz, which are popular capacity on market. And they custom an outer display packaging for each unit, which has ensured their packaging is compact and portable, fitting easily in pockets or bags.

Burt’s Bees uses high-quality printing for vibrant and clear branding. It uses earth tones and natural colors that reflect their commitment to nature and sustainability. The packaging features a minimalist design focusing on essential brand elements. And we do not see any foiling and other finishes on its printing, Burt’s Bees keeps it simple, focuses on straightforward printing, it believe simple is beauty.

Choosing the right paper material for your lip balm packaging is crucial as it affects the printing method and the overall look and feel of the packaging. Here’s a fun and lively overview of different paper materials (coated paper, kraft paper, specialty paper) and the printing methods best suited for each, along with the effects they produce.

Description:

Printing Methods:

Effects:

Description:

Printing Methods:

Effects:

Description:

Printing Methods:

Effects:

Choosing the right combination of paper material and printing method can significantly impact the look and feel of your lip balm packaging. And by understanding the strengths and effects of each paper material and printing method, you can create packaging that not only protects your product but also effectively communicates your brand values and appeals to your target audience.

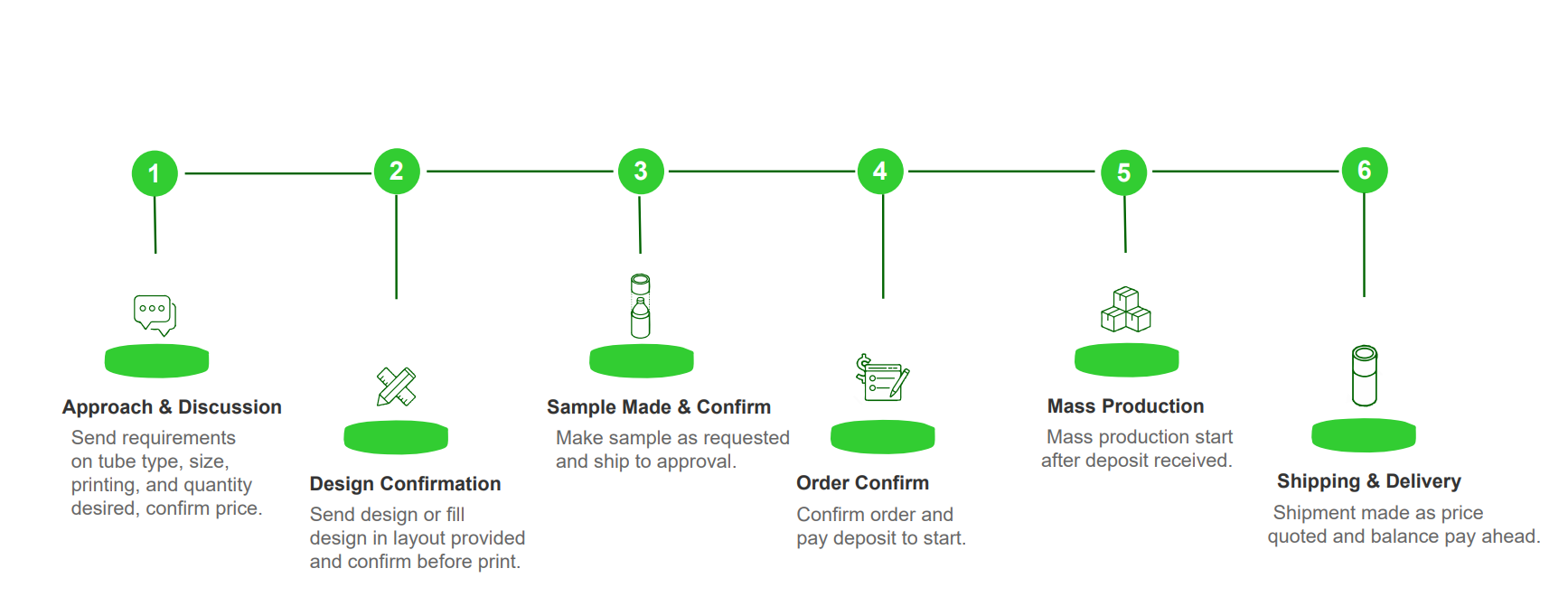

Creating custom paper lip balm packaging is an exciting journey! Here’s a lively breakdown of the process from initial communication to final delivery, ensuring your brand’s packaging is perfectly tailored to your needs.

Reducing costs on custom paper lip balm packaging can be a fun and rewarding process! Here are some easy and effective strategies to help you save money without compromising on quality.

Choose the Right Materials: Opt for more economical and eco-friendly materials like coated paper or kraft paper instead of pricier specialty paper.

Maximize Material Use: Design your packaging to minimize waste and make the most of the materials.

Compare Suppliers: Shop around to find suppliers who offer the best value for your money.

Keep it Simple: Avoid complicated designs and decorations that can drive up printing and production costs. With each additional process, the cost will correspondingly increase.

Standard Sizes: Stick to standard packaging sizes to avoid the extra costs of custom molds and production adjustments. And for products with similar sizes, customizing a single size of paper tube packaging, rather than separately customizing different sizes, can effectively reduce costs.

Order in Bulk: Larger orders can help spread out the costs, making each unit cheaper.

Share Production Batches: Team up with other brands to share production batches and split the costs.

Choose Cost-Effective Printing Methods: Go for more affordable printing options like flexographic or digital printing instead of expensive spot color or foil stamping.

Streamline Processes: Cut out unnecessary production steps to save on processing costs.

Optimize Shipping: Find the most cost-effective shipping methods and routes to reduce transportation costs.

Cut Out the Middleman: Work directly with manufacturers to avoid the extra markups from middlemen.

Build Long-Term Relationships: Establish long-term partnerships with suppliers to get better prices and services. Plan and Order Ahead: Avoid last-minute orders that come with rush fees by planning and ordering in advance.

When considering the environmental impact of paper packaging for lip balm, it’s essential to understand how different printing processes and materials affect the degradation process. Here’s a breakdown of the key factors:

Paper Material Degradation:

Wax Paper:

Oil-Resistant Paper:

Poly-Coated Paper:

Traditional Inks:

Soy-Based Inks:

Plastic Lamination:

Biodegradable Lamination:

Foil Stamping:

UV Coating:

Embossing and Debossing:

By choosing the right materials and processes, brands can ensure their packaging is not only appealing but also environmentally responsible.

All Paper Tube company is committed to developing eco-friendly packaging solutions. In addition to customizing paper tube packaging to meet customer specifications, we prioritize environmental protection at every stage of production. The customized lip balm paper tubes use natural wax paper liners that are oil- and moisture-resistant, and the outer paper is printed with eco-friendly soy-based ink to minimize environmental impact.

To create a paper tube packaging that is 100% recyclable and biodegradable, careful selection of materials and processes is essential. Here are some suggestions:

By following these methods and steps, you can successfully customize a fully recyclable and biodegradable paper tube packaging, highlighting your brand’s commitment to environmental protection.

As a consumer, using paper tube lip balm packaging is not only simple and convenient but also allows you to make eco-friendly choices in your daily life. Here are some ways to recycle and reuse paper tube lip balm packaging:

By recycling paper tube lip balm packaging, consumers can actively participate in the brand’s eco-friendly initiatives and feel connected to the brand’s green values:

As a brand, using recyclable paper tube lip balm packaging not only reduces environmental impact but also enhances the brand’s eco-friendly image and boosts market competitiveness:

Brands can take the following steps to ensure the smooth recycling and reuse of paper tube lip balm packaging:

Brands may offer recycling reward programs, such as points or discounts, to encourage consumers to participate in recycling.

To ensure the quality and performance of paper lip balm packaging and to address whether the melting of the balm is related to the paper tube packaging, please note the following storage and filling considerations:

Temperature Control:

Humidity Control:

Storage Environment:

Appropriate Temperature:

Filling Process:

Temperature Sensitivity:

Paper Tube Selection:

Balm Formula:

A user conducted a test by placing a filled paper tube lip balm in a high-temperature car trunk and found that the lip balm melted and leaked out of the paper tube. This situation is primarily due to the following reasons:

By following proper storage and filling methods, you can effectively ensure the quality and performance of paper lip balm packaging. Controlling temperature and humidity, choosing the right paper tube materials, and ensuring the stability of the balm formula are crucial for maintaining product quality. In high-temperature environments, the melting of the lip balm is mainly due to excessive heat. The sealing and material selection of the paper tube also play a role. To avoid such issues, users should store lip balm in cool environments and consider improvements in packaging design and balm formulation to enhance stability in various conditions.

It would be best if you worked with a professional lip balm paper tube packaging factory. They will help you get quality lip balm paper packaging and eco-friendly custom solutions and affordable prices.

Contact us if you have any questions about custom paper tube on lip balm, deodorant too.

In the current coffee industry, many brands are finding […]

Packaging, presumably a significant portion of your bud […]

Shaker Tube Packaging: A Modern Twist on Convenience an […]

All Paper Tube Co. provides intelligent and innovative cardboard paper tube packaging solutions, from design, research, development, and production.

We hope to build a sustainable and greener future for our planet, together with you.

Copyright © 2022 Orr Industrial (Shenzhen) Co. | Sustainable Packaging Solution Provider

It is an easy step, fill out the form and we will be in touch shortly.