What Makes Sustainable Paper Tube Packaging the Ultimate Green Solution?

Pinterest Every year, the world produces over 400 million tons of plastic waste, with packaging contributing to nearly 50% of that waste. Shockingly, less than

Custom paper tubes allow different customizations on surface finish, these finishes will make the tube packaging look standout and attractive on the shop shell, which will be liked by customers. What finishes can we choose from and how to apply them on the custom paper tubes, it’s not easy for a beginner. Here we’d introduce the top 5 surface finishes we proceed on custom paper tube packaging.

Matt Lamination is the most popular choice for custom paper tubes. Its less reflective finish can lessen the intensity of colors, looking paler and slightly duller, but more muted compared to gloss lamination. And it’s to be prone to scratching and showing fingerprints. While these muted features make matt lamination on custom paper tubes to give a look of high-class, it shows to a consumer luxury and it’s been the most popular way to establish tubes packaging & products as high-end.

Gloss Lamination is totally opposite, the light reflects off the cover, giving a look of a shiny finish. It’s visually attractive, rich in colors and it’s durable, dirt can be wiped clean easily, offering great protection. While wrinkles, scratches & fingerprints are more visible in a brightly light environment.

It’s hard to tell which one is the best option, they get different effects and look different on custom paper tubes. During our paper tubes custom proceed, matt lamination is to be applied more, we think it’s because it gives us a luxurious look.

Foil stamping is a printing process to uses metal dies, heat & pressure to apply foil films on a printing art paper. The foil film is a very thin film coated with colors, it acts as a carrier and then transfers the colors onto the printed paper by stamping process.

There’re wide colors of foil stamping, gold foil, rose gold foil, silver foil, and metallic foil common in the custom tubes packaging process, while there’re more and more to be chosen from. It’s used to emphasize the brand/product name, logo, or any content you want, making the tube packaging a touch of luxury, look premium, and eye-catching.

UV is short from ultraviolet, it’s a special varnish called UV varnish. The UV process on custom paper tubes is to cure the UV varnish onto the artwork by using UV light. And Spot UV is to apply this process to specific areas of the artwork, to make that area an eye-catching contrast, and make the full paper tube packaging lively.

During our custom paper tubes packaging process, Spot UV normally is used to make a contrast on the brand/ product name, logo, image, or outline of the image, also any areas you want to get

As we can see, they’re two opposite finishes, Embossing is to create a raised image by applying a metal die from behind the substrate, it’ll leave a mirrored indentation on the other side of the paper. While debossing is to create an indent in front of the paper by pushing the die onto it, it’d not leave an imprint on the rear of the substrate if the substrate is thick enough.

These two finishes add a unique dimension to our tube packaging, it’s a small yet subtle difference in surface texture will make us feel something interesting when we handle & touch it. It also brings us elegance & luxury sense. And they’re used in special areas too, such as on logo images and brand/product names, similar to the handling of Spot UV, these are the common operation in our tube packaging custom process.

By now we know about these finishes and their differences. They can be all applied on tube packaging, but we highly not suggest it, as it’ll make our packaging odd rather than standout, we kindly suggest combining two of them at a time on tube packaging if we want these finishes effects, for example, we can do foil stamping & emboss both on a paper tube packaging, it’ll make the packaging really attractive.

If you’re a beginner just turning to paper tube packaging, and still get confused about choosing these finishes, and customization issues, you can refer to our paper tube portfolio and custom services we provide, you’ll know more details about the paper tube packaging, or you can just contact our specialist directly, we’ll provide you professional tube packaging solution.

Pinterest Every year, the world produces over 400 million tons of plastic waste, with packaging contributing to nearly 50% of that waste. Shockingly, less than

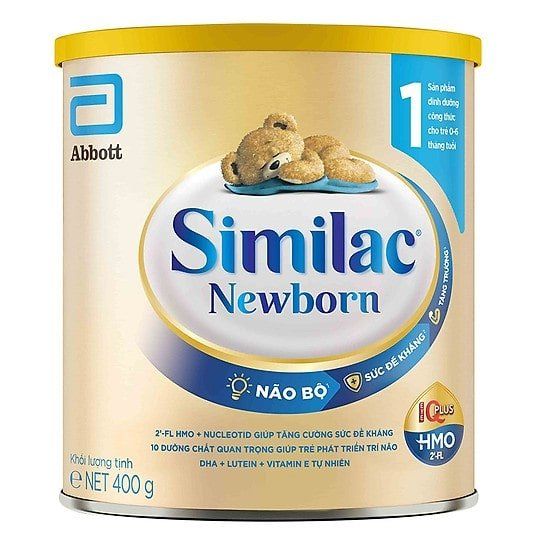

Powdered products—ranging from protein supplements and baby formula to industrial chemicals and pharmaceuticals—require specialized packaging that protects against moisture, oxidation, and contamination while maintaining freshness

The Future of Lip Balm Packaging is Here! Imagine this: You reach for your favorite lip balm. Instead of the usual plastic tube, you’re holding

Consumers are becoming more conscious of the environmental impact of packaging, especially in the food industry. Traditional plastic and metal containers contribute to waste and

Once Upon a Time in a Plastic-Filled World… In a world overflowing with plastic lip balm tubes and deodorant sticks, a small but mighty hero

Airtight powder packaging design from Pinterest When it comes to storing and transporting powdered products, airtight sealed powder packaging plays a crucial role in maintaining

Milk powder brands have traditionally relied on plastic and metal containers, but these materials contribute significantly to environmental waste. With growing consumer demand for sustainable

Shipping costs can be a significant concern when ordering paper tube packaging. Although paper tubes are lightweight, shipping agents often charge based on volume rather than

It is an easy step, fill out the form and we will be in touch shortly.